We live in the Perm region, it’s not that Siberia, and not quite the Urals, but nearby. And the weather is appropriate - the summer is short, frosts in spring and autumn make this “short” very small. Therefore, every self-respecting gardener in our country has a greenhouse on the farm, and often more than one.

Mostly grown cucumber tomatoes. Bell pepper still, perhaps. By the way, letting the tomato ripen on the bush is unacceptable luxury, it is torn off brown, and it reaches its tomato condition on the windowsill. A joke on duty is in use - (our district -) the edge of evergreen tomatoes.

Perhaps the times have passed, when the only way to grow something, despite the weather, was to make the greenhouse itself, with its own gold and sometimes people paved for something that was pulled to capture for memory, in a word, to the best of strengths, abilities and building-locksmith or carpentry carpentry skills. From which it is not a pity. Nowadays, when spaceships plow the big theater, the chemical industry never ceases to amaze with inventions, the other day, which seemed almost fantastic. Cellular polycarbonate was invented. The material for the greenhouse "fence" is just a miracle how good, only infection is a little expensive. Again, ready-made greenhouses, in a disassembled form, are universally offered for purchase. A kind of designer "do it yourself", A la Ikea. Sizes and, accordingly, the cost of choice.

Generally speaking, to buy something ready, which is not so difficult to do yourself, we consider to be bad manners - it turns out to be pretty cheaper, often more accurate and more durable. We conceived a greenhouse for a long time, but all hands did not reach. In addition, in the process of studying third-party experience in greenhouse construction, an amazing design was found - the Ivanko vegetarian. For those interested in gardening, I recommend that you curiosity, the book is easy to find on the Internet. It was decided to build it, with adjustments in size for local conditions. And even the place was found almost perfectly meeting quite unusual requirements for placing a greenhouse - a strong slope towards the south, southeast. However, a veggie is a much more capital version of the “classic” greenhouse, and even by the roughest estimates, requiring a fair amount of money and time for construction. Of course it’s worth it, but there were more priority construction tasks, so for now they were putting it off.

This winter we were presented with a greenhouse. Factory. Of course, this is not a vegetarian at all and it’s worth it, but for the money, you could buy so many pieces of iron and carbonate, and make three, no, four times as much! But no, nevertheless, the thing is very, very not bad, and its main advantage is that everything is already ready, only assembled. Yes, and we still decided to improve it. To begin with, the foundation, the site we have, hmm ... well, not very smooth, we can say heaven for a landscape designer, but also with the presence of a flat place under, say, beds ... well, not very good. So, for evenness and fencing of beds. Plus, the mass is an anchor that will not allow the entire structure to fly away with a decent gust of wind. So, what else do we have Comrade Ivanko invented there? Yeah, a dirt heat accumulator. As the Hunter said in the movie Ordinary Miracle, - "New ... new ... tempting, damn it ...". Well, then, take it.

What did you use.

Instruments.

First of all, a marking tool - used a 30m tape measure, home-made “arshin”, all kinds of pegs, ropes, a compass. The trench tool is a strong shovel, a sledgehammer. Garden car. A simple carpentry, carpentry tool, a screwdriver was very useful. A small concrete mixer with a manual drive, such as a meat grinder, was involved, of course, all kinds of buckets, troughs for concreting. I used a lot of welding inverter, electric cutting machine (grinder). A good extension cord came in handy. Locksmith tool.

Materials

In addition to the greenhouse itself, not very conditioning boards were used for formwork, roofing material for it, reinforcement for the foundation. Materials for the preparation of concrete. Rectangular pipes for additional braces. Pipes for external sewage with a diameter of 110 mm, for underground ducts, plus the corresponding tees-corners. Aluminum flexible hoses, fans, wires. Old slate for fencing beds.

So, photo chronicle with comments.

Spring, the long-awaited sun, warm, wait! Accordingly, with a shovel, it’s just the same pleasure to warm up.

"Zero cycle", as we say - diggers of all trenches. A collar, called "castoff", marking on it.

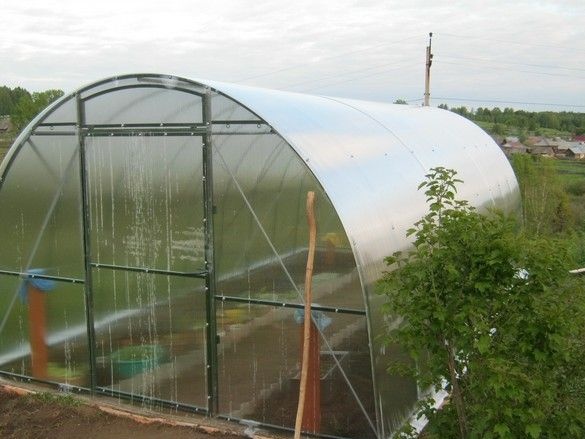

Here she is my beauty! In the words of the Foreman from Operation Y ... "by the power of your imagination, imagine what a wonderful housing estate here will be"

Something was dealt with in the sense of boards; for some of their economy, it was necessary to make the formwork in parts and rearrange it as it was concreted. Moreover, after concrete work, planks are considered lost for decent carpentry use.

Such T-shaped reinforcement elements had to be welded and placed in key places - the upper shelf will be exactly flush with concrete and to it by welding, then we will attach the frame to death.

A view of the corner.

Done! Oh back, oh arms and legs ... By the way, a lot of "hollow-forming elements" were laid in concrete, namely, bottles and pieces of polystyrene foam. Here and generally in wooden construction, the strip foundation is redundant and wasteful in the sense of materials. But then you do not need to plug any holes between the columns with anything, they swam, we know. But like that - with cans and bottles, it comes out rather economically, although, of course, you still have to tinker with it. Again, warmer.

He instructed the child to drill holes in pipes — she loves to drill, there are many pipes, holes too, everyone’s joy — energy, so to speak of the atom, in a peaceful way. Holes, that is, holes, evenly throughout the pipe from below, so that condensate falling on the inner surface of the pipe goes into the soil. After all, the pipes are underground, which means their walls are colder than the passing warm air, and moisture condenses from it. Almost drip irrigation.

That means, the finished assembled duct under the eastern bed.

The same pipes, a slightly different look. For clarity.

Soooo Fitted-sawn-drilled and finally assembled, the "right channel". And cubic meters of soil here and there ... ohohonyushki.

The ends of the pipes, without fail, are to be tucked-to-bind. Once this habit very well saved nerves and means.

Trying, looking at night. Well what to say.Not without some flaws, but everything seems to be falling into place.

Strengthening went - braces, struts, braces ... Boiled in full. I admit, I learned recently, but I love this business very much. Before, how are you going to do what and get to the need for welding, your hands will drop, and now ... just the same, I can! In the frame of the greenhouse, I must say, very thin-walled pipes were used and I had to prettyly make holes, remembering with a small plumb bend, those who saved so much when constructing. But he picked up the electrodes, the current, and it went. By the way, the internal "interior" was formed somewhat spontaneously. The initial configuration seemed flimsy. The design was as follows - welded, staggered, poked, cut off. As a result, the design for which the purchased materials were not satisfactory turned out to be satisfactory; Yes, the manic strengthening of structures and structures that, no matter how significant sailing is, is not a whim, or rather, not quite a whim. Our place turned out to be very, very windy, and it happened in stormy weather from the open veranda that the refrigerator was blown away. So to avoid and for your own peace of mind.

Here, the “pediment” is shot in order to make it convenient to call in a wheelbarrow - to carry compost “from outside”.

Modifications are painted only in places close to the transparent fence, so as not to bite the polycarbonate later, then the rest, under the roof, is a very wet year, every day it rains.

In Trelloni’s voice from the movie Treasure Island, “Admire Our Beauty ...” and further on.

Each sprout, with a sigh of relief, said, “Well, finally!” With seedlings, it’s generally difficult for us. The houses are not so light, the windows open onto the open (so far) veranda, that is, not a lot of sunshine and a lot of sunshine over them. Fluorescent light also does not add much light. All the same, the sun is the sun and it is difficult to fully replace it with electric lighting. Sprouts are pale and frail. And here is the beauty!

It was thought that this motor with a centrifugal fan should be installed for suction of air, at once on two “channels”, but after all ... hands-hooks ... were too lazy to dash after the tester, connected the wires as an inner voice suggested (there were three wires, one is very similar to ground). Well, that ... smoke, stink. The motor set off to places rich in game. I had to look for something else. The list of candidates was, frankly, small, from one point. Fans from pulsed PSU system units of a computer.

This is the process of their implantation in flexible aluminum ducts. The top of the mayonnaise bucket is glued with silicone (neutral, or thin aluminum is eaten!) Sealant, and a fan is already crashing into the lid of this bucket. The lid with a fan was jammed onto the end of the duct equipped with a mating part, the wiring was connected and the order - tightness, maintainability, simplicity of design, low cost.

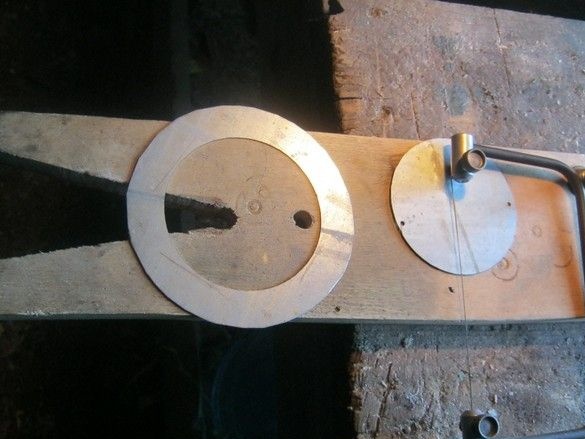

From a roofing "galvanization" sawed a ring. Once again I was amazed at how convenient a jewelry jigsaw tool is (I recently got it, I haven’t got enough of it yet). Previously, I would have to drill a bunch of small holes, then with a file, then straighten this bent disgrace ... br-r.

Yeah, here is the assembly. The prototype, so to speak.

After a few days, he cultivated a little - he sawed up the screws and pulled the mesh so as not to arrange a cemetery in the pipes home animals ...

This is why the ring was needed.

Tee for 12 volts.

The air intake is also with nets, practice has shown that it is not in vain, garbage would have piled there over the season ... By the way, the planted tobacco seedlings are in the photo, a variety that does not require fermentation.

A window leaf on the north side was initially ignored, but it was needed. I had to level the air ducts, fortunately it is not difficult.

I adapted a barrel for watering with water warmed in the sun. Previously, it was heated with water for washing, on an impromptu hearth, almost a fire. Here her monstrous soot turned out to be the way.

After some time, a pair of such channel fans, 220 volts, were purchased.

Installed instead of computer, "blowing". Changed the configuration of the ducts.

The time has come to gather our courage and cultivate temporary wires on the earth. Thick power cable (heating), thinner pair of wires (separate fans and lighting) and a cable with twisted pairs for sensors. All this good was evenly distributed and shoved into two pieces of a metal-plastic water pipe. There were still dances with a tambourine, but overpowered. All this got into the workshop not deep underground.

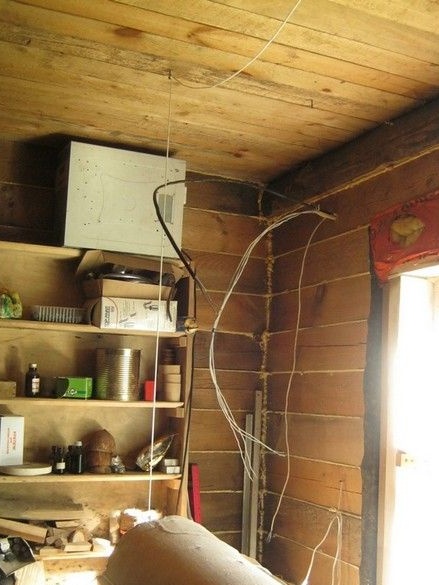

Here, under the ceiling, the unfinished ends in the workshop and the control controller on the shelf are visible.

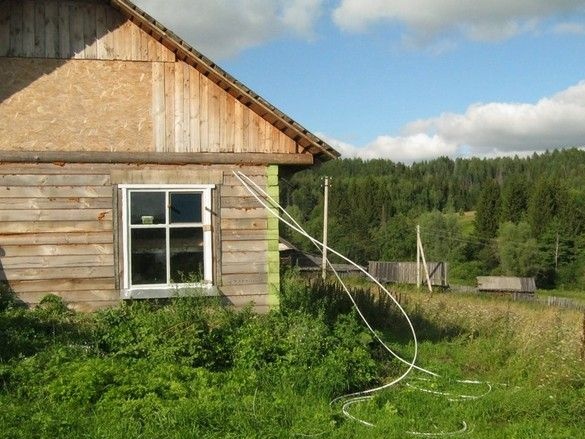

From the workshop window.

Season worked, now hibernation. The fans are disconnected and hidden in a warm place, the sleeves are tied with plastic bags so that no debris, dust, insects are packed inside. The greenhouse is used for seasonal storage of garden supplies, materials.