If you do not know how to fill the empty space of the wall, make a watch with a large dial. The diameter of the watch dial made by the Master is 1.22 meters. For their manufacture, the following

Materials and tools:

-Drill;

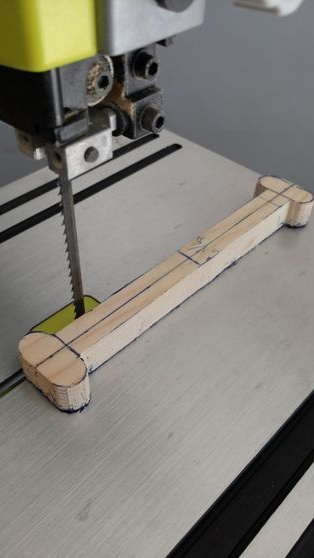

- Jigsaw;

-Sander;

-Band-saw;

-Protractor;

- Roulette;

-Level;

-Putty knife;

-Miter saw;

-A circular saw;

-Paint;

-Brush;

-Board;

-Sponge;

- Stain;

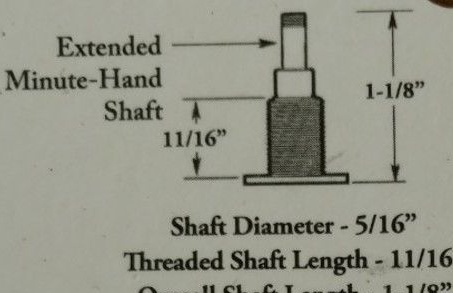

-Clockwork;

-Bar;

-Rail;

-Polyurethane;

-Fasteners;

-Cord;

Step one: numbers

The numbers on the clock, the master decided to make Roman. First I made wooden patterns I, V and X. The remaining figures were made of polyurethane from the patterns. The numbers are 19 cm long.

Step Two: Painting

Paints wooden numbers with white paint. For uniformity, it also paints numbers from polyurethane.

Step Three: The Dial

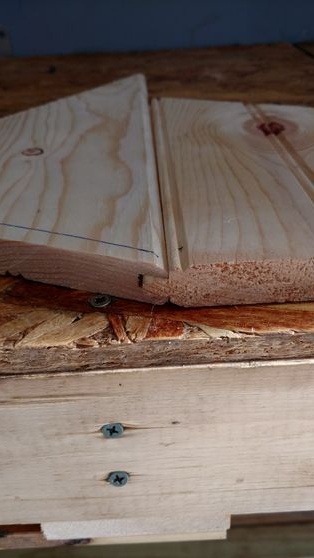

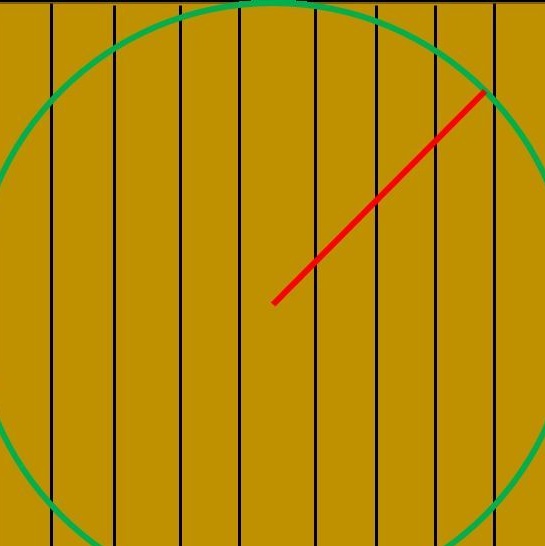

The dial is made of boards. The boards have a spike-groove connection. Connects nine boards. Finds the center. Fastens the end of the cord in the center. Draws a circle with a diameter of 1.22 m. Cut the dial.

Covers the front surface with stain.

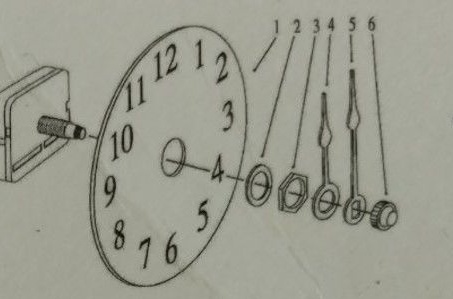

Step Four: Clockwork

From the back, in the center, makes a through hole for the shaft. Secures the clockwork.

Step Five: Build

Makes markings on the dial. The numbers are fastened with screws through the board from the back. That would not be mistaken makes a landmark from the cord.

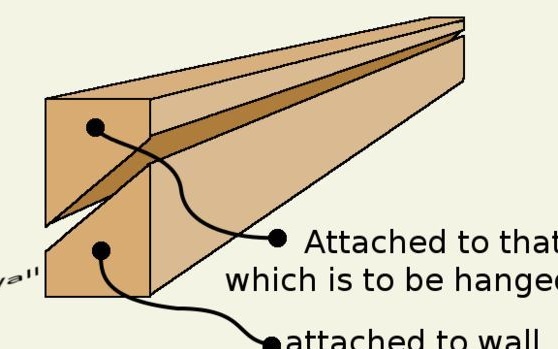

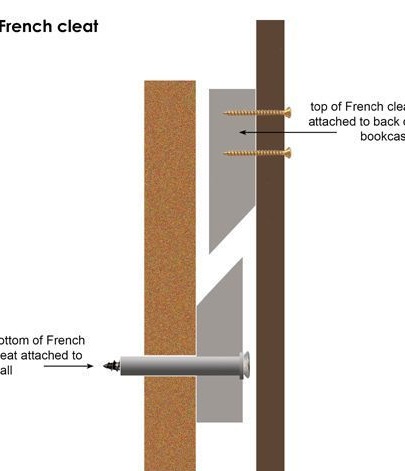

Cuts two bars in half with an angle of 45 degrees. Fastens two halves on the dial from the back. The remaining two are attached to the wall.

Sets arrows.

The watch is ready. Hangs them on the wall.