Despite the development of the gas industry in our region, a centralized gas supply for the villagers remains something unattainable. Cooking - replaceable gas cylinders, heating, mainly wood stoves or makeshift boilers. The latter are often combined with an electric boiler. Recently, the cost of gas and services for designing, conducting, connecting the highway has increased significantly and amounts to more than 100 thousand rubles. Gas bills are impressive and if in the old clay days when there was main gas in a private house, the owners skated like cheese in oil, now the advantage (compared to firewood) is only in ease of use - there is no need for a firebox (morning, evening), no garbage in the house, there is no need to organize special places for storing firewood (of a rather significant amount), to carry logs here and there, to take care of timely acquisition (a year and a half for drying), and even the little things.

It’s convenient, which is already there, however, the cost of firewood in our region is low, moreover, the inhabitants of the villages have the right every year in the local forestry to “prescribe” a certain amount of wood for independent firewood harvesting. As a rule, the people delegate their right to people specializing in logging operations, having special equipment, skills, and personnel. In exchange, the latter bring the agreed amount of firewood for free. Logs, lumps chopped by logs, how to agree.

Here, it is also worth remembering that the reserves of fossil fuels on the planet are not rubber, but wood, which is one of the few renewable sources of fuel. Indeed, when a tree grows, in a tangible form, solar energy actually accumulates. Proper and controlled felling, the forest is only beneficial - old and diseased trees, lumberjacks are destroyed, after felling, they are obliged to plant seedlings of young trees and make sure that they have taken root. Of course, it is unlikely that it will be possible to significantly improve the environmental situation by moving to stove heating, but it’s still nice.

However, to the point. The choice of a furnace, and more generally - the type of heating for a home, is a serious matter. Based on local characteristics, the aforementioned, and also taking into account low incomes, the heating was adopted stove, wood.The boiler probably has the best performance characteristics, however, such a heating system requires considerable funds, constant maintenance of temperatures above zero or the use of expensive chemicals - “antifreezes” or electricity at a positive temperature. In a word, a heat-intensive heating furnace, convection-type heating, was chosen as a relatively simple and inexpensive heating option, uncritical to periodic freezing. Requirements for a heated room, such as the presence of fairly large openings for moving warm air, were fully respected.

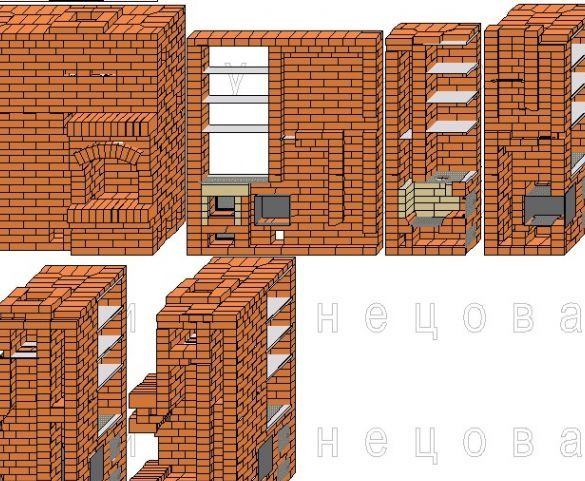

The design of the furnace was chosen by OVIK-5 Kuznetsov.

This is a bell-type heating and cooking stove with a firebox, lined with refractory bricks, a two-burner stove, an oven and shelves. Thermal power with two furnaces per day, about 4 kW / h.

In the fall, the foundation was made for her. Winter was the idea of a stove with a fireplace. A similar stove was chosen, but with a fireplace in the back. Her configuration allowed to do modernization of the "old" foundation, which was performed in the spring. I had to sweat.

New OVIK_ZK13 furnace. Everything is the same, but a small fireplace is “implanted” at the back, connected through a smoke chamber to one pipe with the stove. The pipe is larger. Thermal power comparable to OVIK-5.

It was needed for the laying of the furnace.

Instruments.

The main tool of the stove-maker is a special trowel or trowel. It is more convenient small and narrow. Certainly a cutting machine (grinder) with a diamond disc, a rubber mallet, a rule or a good straight rail a meter and a half long. Protective transparent visor or glasses, headphones. A set of ordinary locksmith tools, marking tools, level, better short and long. Ropes A screwdriver came in handy. Used welding. To prepare the clay-sand mixture, it is convenient to use a powerful low-speed drill with a stirrer attachment. Tanks for soaking bricks, materials, water, clay soaking. A large sieve for sifting sand and rubbing-filtering clay.

Materials

It is clear brick, clay and fireclay. Clay, sand, mortar or a special composition for laying refractory. Basalt cardboard. Asbestos cord. Steel annealed wire or thin perforated tape for laying in seams. Stove appliances (door, gates). Galvanized or better, stainless steel for shelves. Sheet steel for making an oven or a finished oven. Pieces of boards for the base of the fireplace arch and long slats for the corners.

Temporary stove, made of iron potbelly stove and heating shield in haste - the beginning of winter is in the yard. He warmed water and clay on it, thawed pieces of frozen sand.

The stove floor is ready. By the way, the “verticals” of the slats at the corners are not very convenient, the ropes are better. And it’s more convenient to pull on and do not interfere with the rows align.

I laid out the fireplace arch on such a mold from pieces of boards. I sawed the top with an electric jigsaw, fastened it with self-tapping screws, taking into account the fact that then I will have to carefully disassemble it through the “portal” of the fireplace.

The author suggests making shelves of galvanized steel 0.5mm, however, even taking into account the bending, they seem to be not too strong - to dry the mittens-caps. Broke into 1.5mm stainless steel. It was difficult to get the bend with a small bending radius, and I had not yet guessed to file the material with a cutting machine at half the thickness. Applied welding.

The standard two-burner cast-iron stove in this furnace is somewhat covered with bricks, therefore, it is better to use a continuous cast-iron floor, without burners.

Fire door closure, part of the refractory lining is visible. The corners of the refractory bricks should be sawn so as not to stick out. Then I didn’t guess.

Instead of the classic ash door, a special box was used - practice has shown its significant advantages, I will talk about it separately.

Oven. Oh, this is just a wonderful “option” for a heat-intensive stove. While the family was building and living in the city, it really saved me from fussing with cooking - rice and chicken are cooked in three movements, put at night and in the morning, you lick your fingers.Now, my young ladies are acting up - the stove is more convenient in the electric one, the result is more predictable, but cabbage soup, pilaf, chicken with rice, it's all there, in the stove.

It’s somewhat clumsy from the inside - the material was cut out from a crumpled bath stove, inherited from relatives. In fact, it is worth using heat-resistant and heat-resistant steel. I reasoned that in the bathhouse furnace with its infernal furnace, everything that was supposed to burn out had already burned out, and everything that was deformed would not go anywhere. And so it turned out.

Here's another curious moment - 18 row, see orders. On row 17, you can see the overlap of a small "cap" behind the firebox. Above, in this furnace there is a dull empty space and through a piece of iron, it gradually warms up. He wrote to the stove from the author’s cohort, they say you can put vulgar galvanization, that's enough for our age. I still had a suitable stainless steel trim from the shelves, I applied it.

Seating for valve frames. But it’s interesting, how did the stove-makers get out before, without a diamond disk? Kirochka, ok half or a quarter to chop off, and the rest? The riddle.

Top cap.

Second upper hood and lift channel. Do not forget to periodically climb inside and rub the seams with a wet cloth until the hand reaches out, otherwise it will accumulate where soot.

You can clearly see how the “summer move” works; its latch in the photo is ajar.

Flue gases go along a short path, bypassing the hood, into the chimney.

Well, the stove itself is ready, it remains to connect the chimney and start cleaning, but here they are pretty and to avoid the suction of cold air, which is almost inevitable in the case of using clean doors, the cleanings are laid with half a brick on the rib.

Latches, sawed out "arches" to climb a finger.

The chimney in haste, from two sheets of galvanized steel, fastened with self-tapping screws with large flat hats.

Passed the temporary pipe through the ceiling. At the intersection, carefully wrapped with basalt cardboard.

Order. You can dry it with frequent small smolders, first with slivers, then with chopsticks, then chop each log into 4 parts and so on until completely dry. Also, it's time to do a marathon - wash the masonry until the clay at the seams is dry. Wet rag or large sponge. To water without fanaticism, to change water more often.

This is the current photo.

Yes, in the course of life, when we had normal electricity, another small modernization was carried out - the installation of a small electric heater inside the furnace. Two heating elements of 1.2 kW each are connected in parallel, mounted on a small metal frame. The oven is placed through one of the cleaning holes, under the lower hood. Half of the brick on the edge that covers cleaning is drilled through with a carbide drill in two places (TEN leads), in four places at the corners blind holes are drilled with a depth of 10 ... 20 mm, in them M5 screws are glued to the epoxy resin. A protective cover is attached to them. A hole has been drilled on one side of the casing. From the inside, a neon bulb with a current-limiting resistor is fixed - an on indicator. The tail of the cable goes into the basement, there was installed a programmable thermostat with a powerful contactor.

The electrical part, in the absence of a stoker, made it possible to slightly warm up the house by his arrival. The thermostat was connected to the computer via the COM port, so there was no need to climb into the cold basement for reconfiguration, and the control program looked much more clearly.

Furnace orders and some useful materials from the author’s site: