An ax fell into the hands of an old one, beaten by life and a careless owner.

It was a pity this poor fellow and it was decided to give him a second life.

Tools needed

1. Welding inverter.

2. Angle grinder.

3. A drill on a rack.

4. The plane.

Tools that were used but you can do without them.

1. Grinding machine.

2. Electric jigsaw.

Expendable materials.

1. Electrodes Monolith Life RC 3 mm.

2. Cutting discs.

3. Disk cleanup.

4. Disc cleanup flap.

5. Emery paper of gradation from 60 to 240.

6. Stain under the oak.

Donors helping restore the ax.

1. Chip car springs.

2. Dry log from acacia.

3. Old water meter.

To begin with, we disassemble this disabled person.

Grinder align the edge of the blade and adjust approximately the thickness of the spring.

Weld the spring to the cutting of the ax. First we remove the chamfers from the ax and springs, we weld in three passes, on both sides. It is also necessary to wait until each seam cools completely to minimize overheating.

We clean the seam, if everything suits, draw the desired contour of the ax and cut it out with a grinder.

We clean the surfaces with clean circles, first with ordinary, then with flap circles. In the process, periodically water the part with water. Overheating is not allowed.

If there is a sharpener, then finish grinding and sharpen better on it.

It remains to polish the blade with sandpaper and polish it on a felt circle using GOI paste, but this is optional.

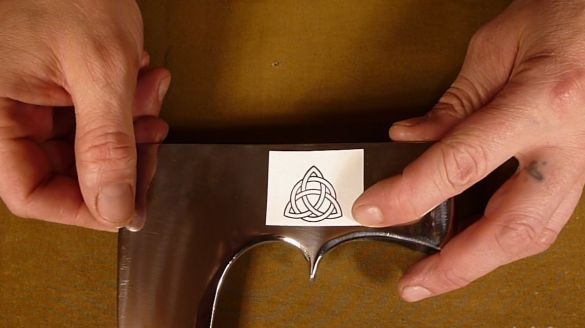

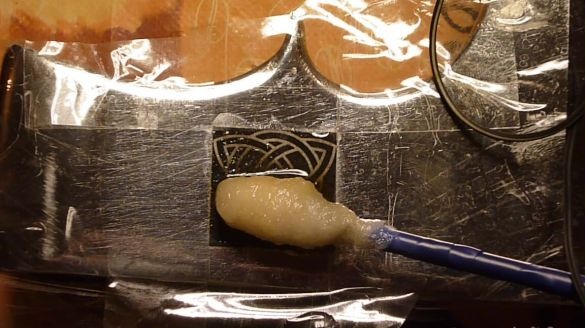

Also, if desired, for decoration, you can make a drawing.

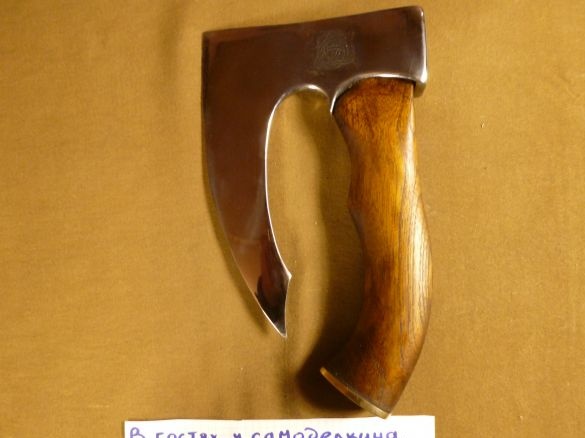

For the ax we use acacia logs.

To begin with, we remove the plane with a plane.

We draw an approximate shape of the handle and cut it with an electric jigsaw.

With the help of a grinder and a stripping flap disc, we give the hatchet a convenient shape.

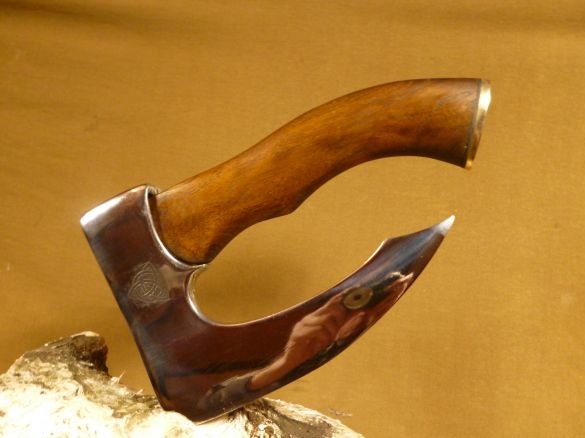

An old water meter came up to make a brass pommel.

We cut off the bottom of the counter, we have a brass blank 5 mm thick.

Mark the contours of the end face of the handle.

We cut and drill one or two holes for attaching to the ax.

We drill holes to tighten the screws in the pot.

If the top does not fit snugly against the handle between them, you can insert a piece of rubber from the car camera, while tightening the screws, it will hide irregularities.

Grind the ax with sandpaper.

Finally we remove all irregularities with a clean felt circle, without GOI paste.

If desired, the ax can be opened with a stain.

We collect the parts together and have a cool ax instead of the old invalid.