Stove heating by wood, implies a certain condition and quantity.

Firewood for burning in an oven should be dried for 1-2 years, and have a maximum humidity of 15%. When using raw firewood, the loss of calorific value can reach, according to Finnish sources, 34-57%. It also leads to rapid clogging of the furnace and increased fire hazard due to the rapid clogging of soot. Part of the heat released during the combustion of fuel is spent on evaporating the water contained in it. The heat expended in evaporating the water is lost with the steam leaving the pipe.

The low temperature of the flue gases and the high content of water vapor in it also cause the condensation of creosote and other dirty tricks in the chimney. A brick pipe gets wet and collapses from the inside - in winter also from freezing moisture, and in a warmer time from the effects of acids on the brick. Also, when tar and creosote run off into the oven, we have a pungent unpleasant odor in the room.

So, it is clear that the harvesting of firewood is not Khukhra-Mukhra, but the whole process. Considering that this process is most of all drying, and also taking into account a fair amount of fuel for three stoves (a house, a bathhouse, a workshop), the problem of a special place for them, firewood, storage inexorably arises.

In the first years of arrangement on your own land, living, at the beginning of hermit's house with a slightly improved potbelly stove, and then, for a while, and in the house with solid stove, firewood had to be dug out from under the snow, and then dried, or rather, dried in a room in a warm place.

Nothing good, I will report to you. Not only that, a lot of space in the hut is used irrationally, but also rubbish, constant shifting-sorting into “ready-made” and “dry a little more”, increased humidity in the house and other minor troubles.

Yes, it’s worth saying here that we are talking about the completion of firewood. From melted snow, autumn rains and other things like that. A year or two drying, a few days on the stove do not cancel. The fact is that in the woods there is native moisture, intracellular and one that will wet from the outside - like rain. So, to reduce the first, to a reasonable limit for fuel, is quite difficult. With natural drying, small-sized pieces of wood - boards, logs, reach the condition for exactly a year and a half. External moisture disappears several orders of magnitude faster.

So, we put the requirements for the construction.First things first - a certain space, quite large, under the roof. It is very good if it is next to the house, so that the firewood is worn closer. Well, as usual, cheaper to.

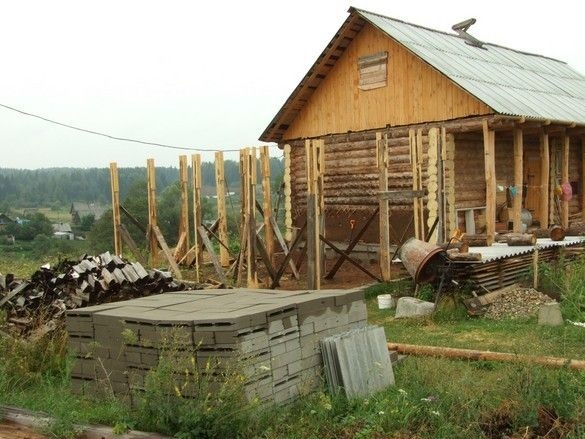

It was decided to make the construction as an “extension” on the north side of the house. A blank wall, the proximity of an empty flat area on the terrain where it is convenient for the tractor to dump logs and where there will actually be a sort of graveyard - a place for sawing and splitting chocks. Docking with the house, found a convenient opportunity - exit from the woodshed immediately to the veranda-corridor. In the future, when glazing the veranda, it will be possible to walk behind the firewood in slippers, which is convenient. Again, one wall was saved.

The floor is earthen, the roof is one-sided, the fence is an inch board (2.5 cm).

What did you use during construction.

Instruments.

First of all, a marking tool - used a 30m tape measure, home-made “arshin”, all kinds of pegs, ropes, a compass. The trench tool is a strong shovel, sledgehammer. Garden car. A simple carpentry, carpentry tool, a screwdriver and an electric planer were very useful. For carpentry, an electric chain saw is very convenient. A small concrete mixer with a manual drive, such as a meat grinder, was involved, of course, all kinds of buckets, troughs for concreting. I used a welding inverter a bit, an electric cutting machine (grinder). A good extension cord came in handy. Locksmith tool. A reliable staircase should be taken care of.

Materials

Not particularly air-conditioned boards for formwork, roofing material for it, reinforcement and steel strip for the foundation were used. Materials for the preparation of concrete. Unedged board for fencing (walls) and structures in the required quantity, fasteners for them (nails, screws), a piece of glass for a window. Roofing - profiled galvanized steel sheets were applied. Special fasteners to them.

It was decided to make a simple semblance of a foundation. In essence, this fence is mainly to prevent meltwater from flowing in the spring. Well, the pieces of wood will be slightly raised from the ground - they will rot less.

After careful marking, a shallow groove is dug, a thin layer of sand is poured into it, after tamping with water, a plastic film is laid on top (an obstacle to drain the concrete mix), a little reinforcement and flush with the ground are poured with concrete. After hardening, from simple improvised means, an impromptu crawling formwork was fixed and concrete was poured into it along the lace level.

Such welded fittings were pre-installed in it. Mentioned in the articles - we live in a rather windy place, and the roof of a large area with a light roof, like the whole building, has significant windage. The task of the elements protruding from the foundation is to attach a light external shelter to at least a massive foundation.

In addition, within the building, several pillars were planned. Separate soles with similar fasteners are arranged for them.

A piece of ruberoid folded in half put on a pin in the middle for waterproofing - a good tone. After, in a pillar laid to one side, with a powerful electric low-speed drill with a spiral drill of corresponding length, a hole was drilled in the center. Then, the pillar just snapped onto the pin. In conclusion of all the work, the strip at each column was bent and through the hole, a "cracker" was screwed into the tree with a wrench. A sort of powerful screw with a turnkey hexagon head.

Excavation works completed - turf removal, soil leveling.

Everything is prepared for woodwork carpentry.

The columns were temporarily fastened by braces and rails to each other. A whole forest of auxiliary boards, but on each pillar, it was possible to climb up, leaning against the stairs. Everything was fixed on self-tapping screws.Then, after the columns are completely aligned vertically, their height is refined by the string, the excess is sawn off. At the end of each, a U-shaped mount is made, prepared thick poles are laid in them. Well, or thin logs. After fixing, the latter, the posts were finally fastened with permanent screeds and braces from the boards. On the roof, a lathing is nailed up and roof sheets are fixed. Special fasteners - self-tapping screws with rubber. Into the crest of the "wave." The sheets are not heavy, and all the work is quite capable of one. Yes, be careful with the galvanized roof - its lateral ends are quite smooth, but the end and the beginning (across the “waves”), where they are cut during production, have edges as sharp as a blade, which is very easy to cut.

All the woods immediately under the finished roof!

The ceiling logs are not too strong and have a significant span, it was necessary to strengthen them with braces on both sides.

The photo shows the structural elements on which the fence boards are attached. The fence itself is made of an “inch” unedged board (much cheaper), planed on the front side (absorbs less water, does not decay longer). The boards are attached with an overlap - two boards are fixed at a certain distance from each other, on top of the gap, another one is attached. This method allows you to use the uneven edges of the boards, with careful execution it is decorative, it neutralizes possible cracks when the wood dries.

Simple doors were made and installed (wide two-leaf so that it was possible to drive a wheelbarrow) to the street and the usual to the veranda. Above the street door, a simple window was made and installed.

The construction turned out to be about 6x7 m in size and performs the function of not only storing firewood, but also a large storage room. Living with him has become much more convenient.