All the good time. Today our hero decided to assemble a mini hand drill or, more simply, an Archimedean drill. According to the author, using such a drill it is very good to make small and precise holes without piling. Who cares about the manufacturing process and the test, read the article below.

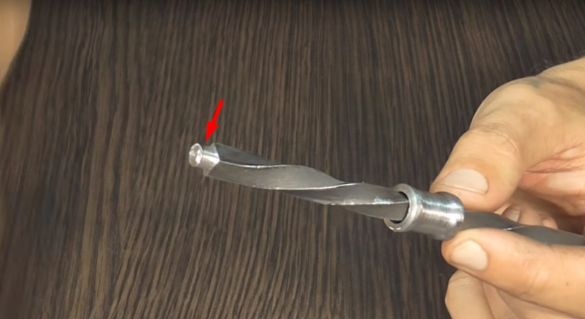

And so, for this tool, the author took a small cartridge. In which he will continue to clamp the drill.

He will also need a steel square of 6 * 6 mm.

Since our hero did not have a finished square at hand, he decided to make it himself from a spring leaf of suitable thickness.

And here is what he did.

Since the spring leaf is very steel, the author decides to let it go a little, he heats it and waits until the square cools completely.

After the square had cooled down, the author squeezed one of its edges in a vice, and put a handle with a square hole on the second edge, and began to turn the handle clockwise. Thus making a screw thread on the square.

Then he made a handle from a round on a lathe with the help of which the cartridge will rotate.

Almost the entire length of the hole in the handle, the author made this size so that the square freely entered into it.

The author made only the last 5-7 mm holes in the handles with a drill of a smaller diameter.

Then, with the help of a needle file, the author will turn the round hole into a square. (From the side where the hole is smaller in diameter.)

Then he heated the edge of the handle with a square hole to red and stuffed the handle onto the thread.

After he gave this pen a neater look and shortened it.

And he also worked one edge of the square under the bearing.

And the second edge is under the cartridge.

The cartridge inside has a cone, so as not to guess it on the square, the author will simply warm the edge of the square and press it into the cartridge. To prevent the author from overheating the cartridge quickly, he lowered it into the oil.

After the cartridge was in place, the author put the handle and bearing in place.

The author put a wooden cork on the bearing.

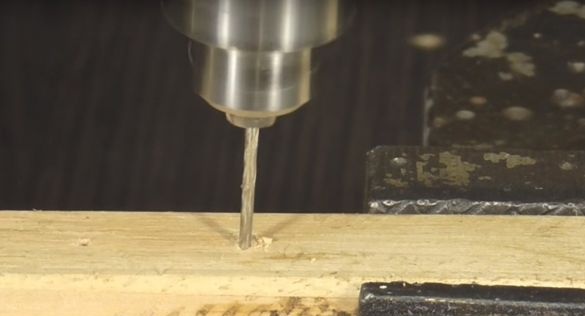

And now the author will clamp the drill into the chuck and test the finished tool on different materials.

Tree.

Plastics

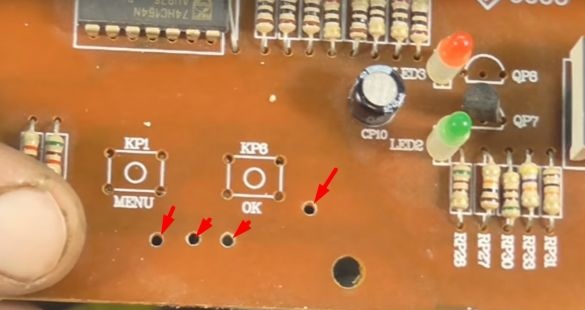

Textolite.

Aluminum corner 3 mm.

As you can see the tool made by the author passed the test on all of the above materials, and the author did not adjust much effort. Also, according to the author, working with this drill feels good drill, and this is the key to its long-term operation.

Thank you all for your time. See you again.

Video homemade: