Hello everyone with you kompik92!

And this is the second part of creating a steam engine!

Here is presented its more complex version, which is more powerful and interesting! Although it requires more tools and tools. But as they say: “Eyes are afraid, but hands do”! So let's get started!

I think already everyone who has seen my past posts knows what will happen now. Do not know?

Safety regulations:

- When the engine is running and you want to move it, use forceps, thick gloves or non-heat-conducting material!

- If you want to make the engine more complex or more powerful, it is better to learn from someone than to experiment! Incorrect assembly may cause the boiler to explode!

- If you want to take a working engine, do not direct steam at people!

- Do not block the steam in the can or tube; the steam engine may explode!

Is everything clear?

Let's get started!

All we need is here:

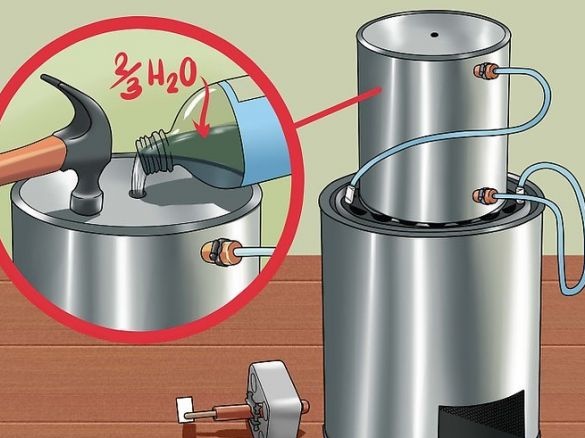

- Jar with a capacity of 4 liters (best washed well)

- 1 liter jar

- 6 meter copper pipe from with a diameter (from now on “dm”) 6mm

- Metal tape

- 2 tubes that are easy to squeeze.

- Junction box made of metal in the shape of a circle (well, it doesn’t look like a circle ...)

- Cable clamp that can be connected with a junction box.

- A copper tube with a length of 15 centimeters and a diameter of 1.3 centimeters

- Metal mesh 12 by 24 cm

- 35 centimeters of elastic plastic tube with dm 3 mm

- 2 clamps for plastic tubes

- Corner (only the best)

- Standard skewer for barbecue

- A dowel made of wood with a length of 1.5 cm and a dm of 1.25 cm (with a hole on one side)

- Screwdriver (Phillips)

- Drill with different drills

- Metal hammer

- Scissors for metal

- Pliers

Uhh .. It will be difficult ... Okay, let's get started!

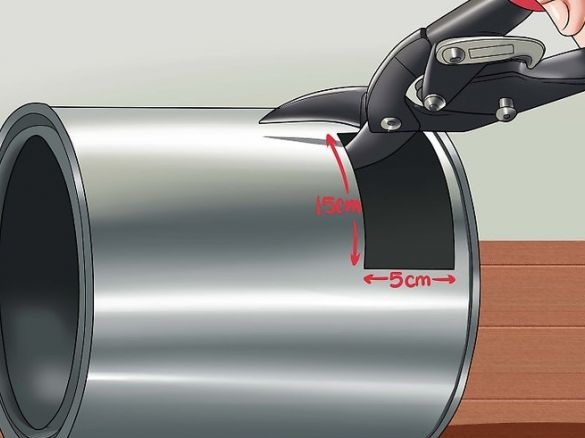

1. Make a rectangle in the jar. Cut a rectangle using pliers on a wall measuring 15cm by 5cm near the bottom. We made a hole for our furnace, it is here that we will set fire to coal.

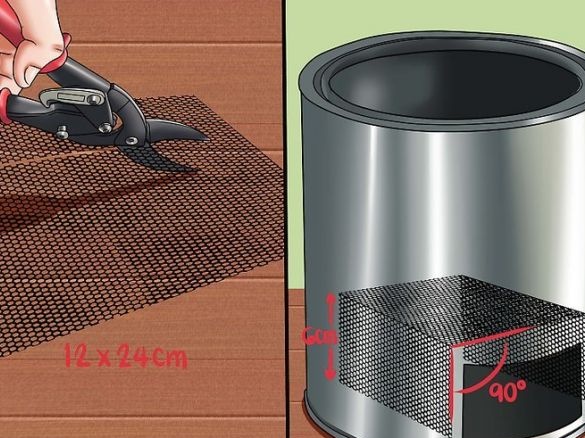

2. Put the grid Bend the legs near the net, and so that the length of the legs is 6 cm each, and then place it on the leg inside the jar. It will be a separator for coal.

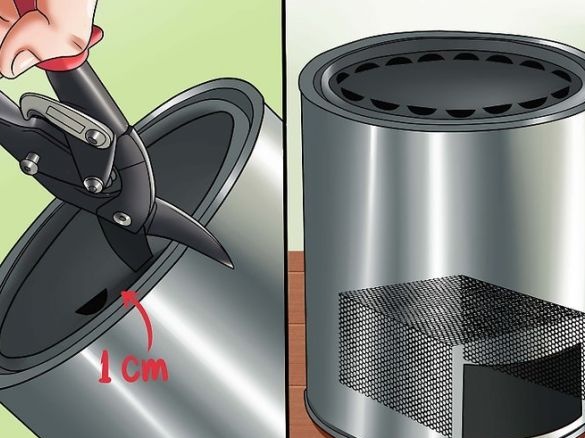

3. Ventilation. Make semicircular holes around the perimeter on the lid, use pliers. For a good fire, you will need a lot of air and good ventilation.

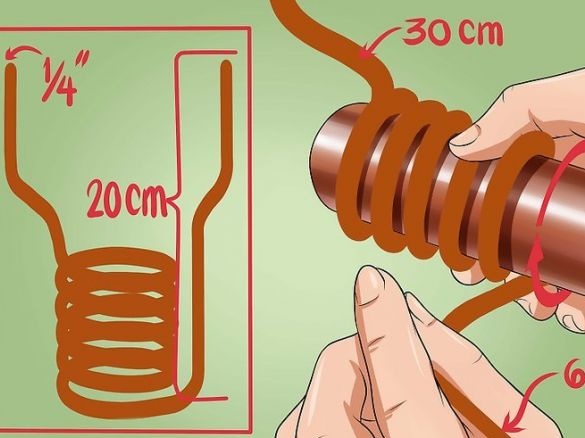

4. We master a coil. Make a coil from a copper tube 6 meters long, measure from the end of the tube 30 cm, and from this place measure 5 skeins of dm 12 cm. Make the rest of the tube 15 skeins of 8 cm each. You will have another 20 cm.

5. Attaching the coil. Fasten the coil through the ventilation. With the help of a coil we will heat the water.

6. Download the coal.Load the charcoal and put the coil in the upper jar and close the lid well. You often have to change this coal.

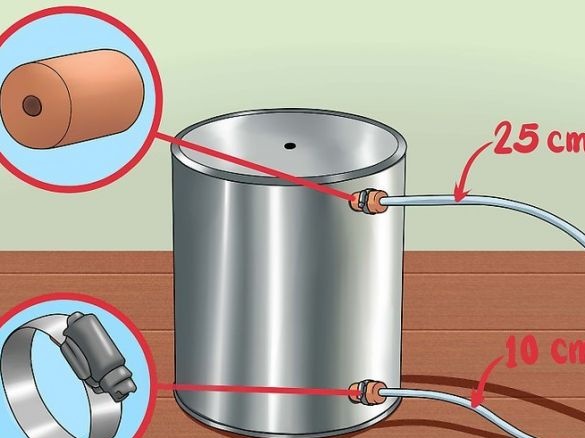

7. We make holes. Using a drill, make holes with a dm of 1 cm in a liter jar. Place them: in the middle from the top, and another two holes on the side with the same dm in one vertical line, one just above the base and one near the lid.

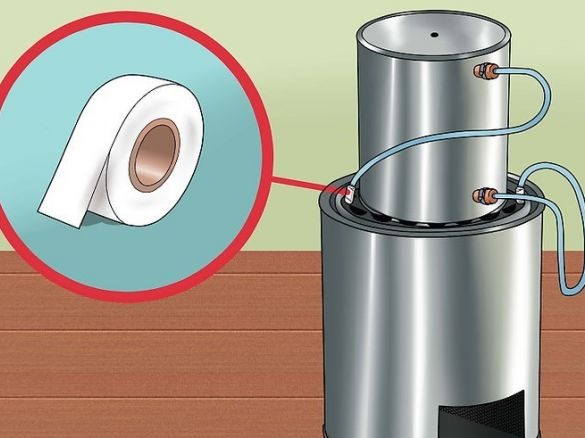

8. Fasten the tubes. Make holes with a diameter slightly smaller than your layer. tubules through both plugs. Then cut the plastic tube into 25 and 10 cm, and then fix the tubes into corks, and in them squeeze the cans into the holes, and then clamp them with a clamp. We made the entrance and exit of the coil, water comes from below, and steam comes from the top.

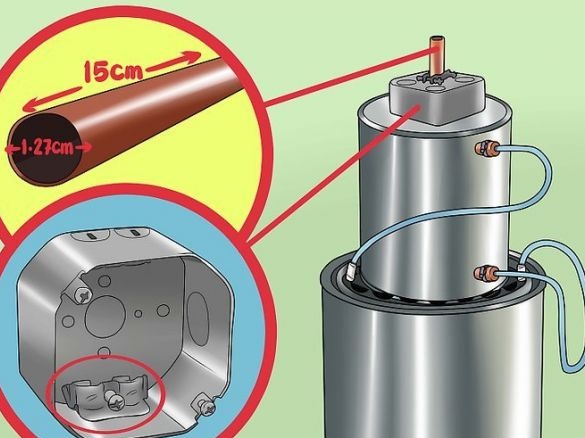

9. Installing the tubes. Place a small one on a large jar and fasten the upper 25 cm wire to the coil passage to the left of the furnace, and a small 10 cm wire to its right exit. Then fasten them well with a metal tape. We fixed the exits of the tubes to the coil.

10. Fasten the junction box. Using a screwdriver as well as a hammer, unhook the middle of the round metal box. Lock the cable tie with the locking ring. Attach a 15 centimeter copper tube with a dm of 1.3 centimeters per clamp so that the copper pipe extends a couple of cm below the hole in the box. Round the edges of the outgoing end inward using a hammer to 1 centimeter. Fasten the smaller end to the top hole of the small can.

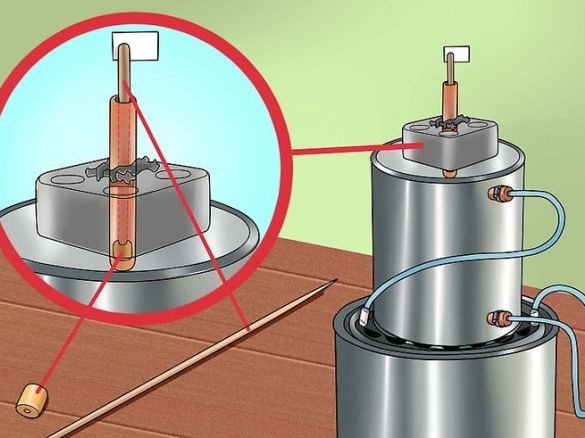

11. Add the dowel. Use a standard wooden skewer under the barbecue and attach either end to the wall plug. Insert this design into the upper copper tube. We made a piston that will rise when the steam is too much in a small bank, by the way you can add another flag for beauty.

12. Preparatory actions. Take away the junction box for a while and fill ⅔ of water in the upper jar (somewhere 0.3333 liters), check that it doesn’t leak anywhere, Close the lids firmly (preferably with a hammer) and put the junction box (also with a hammer) in place.

13. FIRE !!! Crumple a sheet of newspaper and put it in the firebox of our steam engine. Wait until the coal starts to burn. As it warms up, steam will go into a small jar, and after some time it will begin to raise the skewer. Add or reduce the weight of the skewer so that it goes up and down.

DONE !!! Have a nice day!

With you was kompik92!