As the modern Russian proverb says, “Make an ice in the summer and a skateboard in the winter.” Here we will be engaged in the manufacture of a skateboard, under the guidance of a master, in this article.

Tools and materials:

-

-

-

-

-

-

-

-

-

-Plywood;

-Installation box;

-Rule;

-Pencil;

-Band-saw;

- Clamps;

-File;

Milling cutter;

-Sandpaper;

-Drilling machine;

-Varnish;

-Knife;

-Soldering iron;

-Heat-shrink tubing;

-Hair dryer;

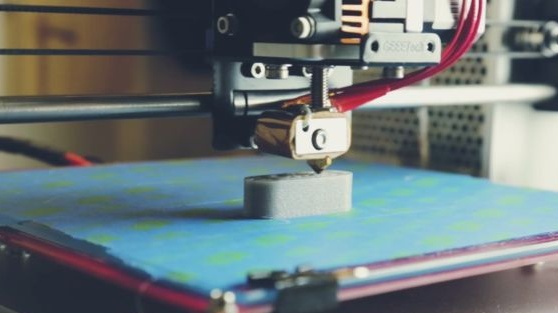

-3D printer;

-Drill;

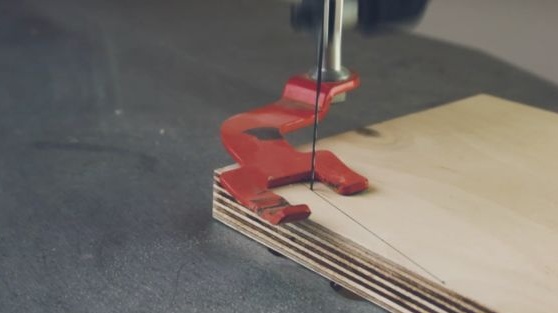

- Jigsaw;

-Glue;

Step One: Deck

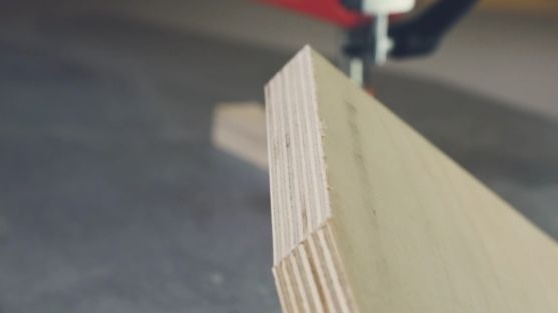

1/2 inch (1.27 mm) thick birch plywood sheet cuts the deck. Processes the end part.

Drills holes for suspension.

Varnishes.

Glue the skin onto the front of the deck.

Step Two: electronics

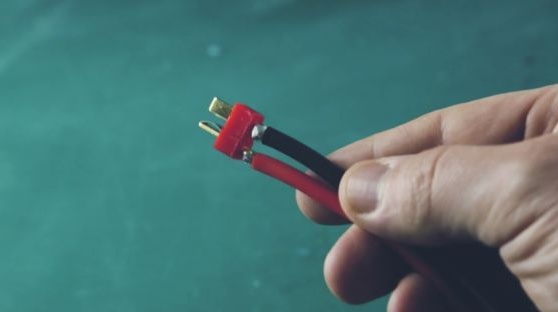

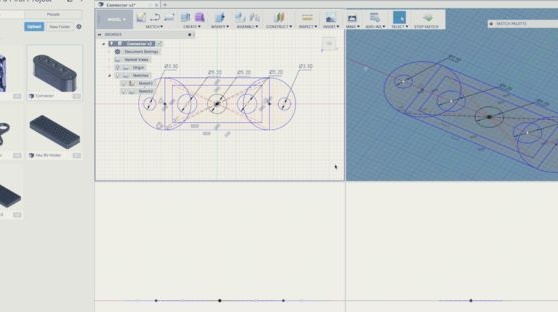

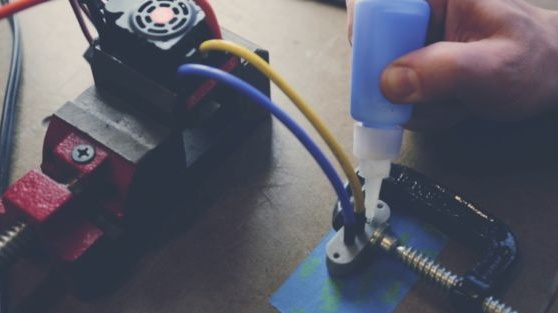

The master replaced the controller's standard connectors with the XT60. He printed a mounting block on a 3D printer. I sawed holes in the mounting box for the pads. Set the pads. Connected according to the scheme: battery-controller, controller-mounting block (then to the engine), controller-signal receiver. I also installed a switch in the circuit.

Step Three: Suspension

Gathers the suspension. Installs engines. Tightens the wheels. Rotational movement, from the engine sprocket to the wheels, is indulged through the belt.

Step Four: Final Assembly

Screws the pendant to the deck. Screws on the mounting box. Connects engine connectors to pads.

Checks the operation of the electrical part.

The electric skate is ready.

You can also familiarize yourself with the manufacturing steps and tested the skate from the video.