In the farm, as well as in a private house or workshop, the garageThere are many processes associated with a change in temperature and a possible reaction to these changes. Moreover, the reactions can be quite diverse and dependent on time and calendar. It can be a “big brother” to look after the aquarium-terrarium or complex step-by-step heat treatment in a high-temperature furnace, control of the heating and ventilation system at home and just making calls at the educational institution.

It is not difficult to solve a similar problem by using a microprocessor-based radio module as a control. For example offered by Masterkit.

Key features of the device.

Timer Control:

Turn on the load in a certain period of time

Load management for specific days of the week, days in a month, or for selected months.

Temperature control (temperature control):

Management as a cooler

Heater control

Alarm clock sound + light (display backlight).

1. The number of connected temperature sensors: 32.

2. Non-volatile real-time clock (full calendar taking into account leap years).

3. Save all settings in non-volatile memory. Continuation of the correct operation of the program in the event of a temporary disconnection from the network.

4. Outputs:

a. opto-isolated cascade for connecting power triacs (optionally - 4 optocouplers are already on the board, it is possible to add 8 more to control external power cascades on thyristors / triacs)

b. logic outputs with a maximum current of 10mA.

5. Remote control of the thermostat via COM - computer port through specially developed software.

7. Indication: 2-line 16-character LCD-display with the ability to programmatically control the contrast and brightness of the backlight.

8. Sound indication by the built-in micro-speaker.

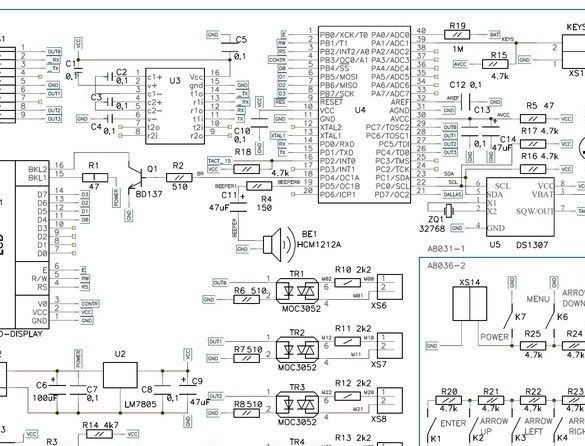

A schematic diagram of the device is presented below.

Circuit description

The thermostat is based on the Atmel Mega32 microcontroller. The following are connected to the input-output ports: text 2-line indicator, DS1307 real-time clock chip, MAX232IN level driver, opto-sims. The keyboard block is made as a separate board. The key code pressed is decoded by the analog-to-digital converter (ADC) of the controller.In addition, the ADC monitors the status of the backup battery for the watch. The voltage stabilizer is made on the LM7805 chip. DS18B20 temperature sensors are connected using the 1-wire protocol. The backlight brightness is adjusted using a transistor switch. Using a miniature speaker connected through an isolation capacitor and a quenching resistor to the controller port, the device can emit sound signals.

The performance of the circuit is ensured by the internal microcontroller program. At startup, the program analyzes the 1-wire bus and initializes the “registered” temperature sensors to a 12-bit thermal conversion mode. Next, all other blocks are initialized (text indicator, RS232 port, clock chip). After initialization, the system enters the main loop mode. In this mode, there is a constant processing of updated information from the clock, from sensors, and the status of the control buttons is also polled. In addition, the process responsible for timer control is constantly running.

The device is offered in the form of a set of radio elements with printed circuit boards, among other things - a microcontroller with a program. Structurally, the assembled thermostat-timer looks like a volume module assembled from three boards. On the largest "motherboard", on metal screw racks, two additional boards are installed - an indicator and a keyboard.

What was used.

Instruments.

A set of tools for radio installation, a soldering iron with accessories, a multimeter. A jewelry jigsaw came in handy. A small bench tool. Something to drill holes, plus drills. Used hot melt adhesive. Construction dryer for working with heat pipes. A soldering iron with a capacity of about 60 watts, for structural soldering. In some places, a drill, a small gas burner, and a screwdriver came in handy.

Materials

The radio designer himself. Radio elements for electronic keys, power supply, also used pieces of foil material for printed circuit boards, different heat pipes, mounting wire, fasteners. Galvanized steel sheet for the front panel, a piece of plexiglass. Access to a computer with a printer.

Initially, the module was used as a control device for underfloor heating in a city apartment.

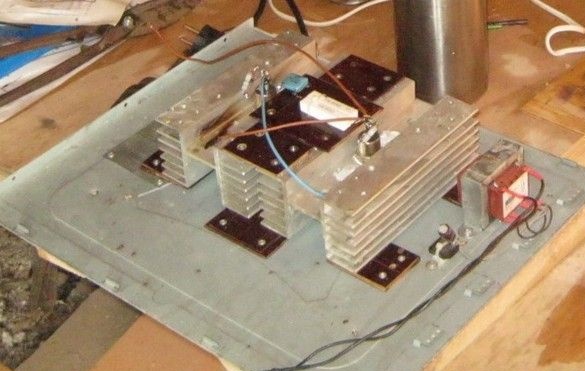

The entire heated area (corridor, kitchen, bath-toilet) consisted of four independent heaters. “Thin warm floors” were laid in a layer of tile adhesive. Together with each heating grid, a digital temperature sensor DS18B20 was walled up. All wires were planted in a dedicated cabinet in the kitchen. There were also some electrical components not related to floor heating - a unit for smoothly turning on halogen lamps in the bathroom (as in a theater, without it they had an extremely low resource), an RCD of the boiler. The control unit was equipped with triac keys on powerful radiators, a power supply. The cabinet had two ventilation grills and a door with a lock.

Above, the circuit of one of the triac keys. The RC circuits shown in the figure, connected in parallel with the thyristors, are recommended to be used to improve their dynamic characteristics. The smallest resistor of the range corresponds to the resistive load, and the larger to inductive. In parallel, the load was turned on by a neon bulb. Placed in plain sight, very convenient when setting up and monitoring work.

In the village, a thermostat-timer was relocated to the casing from the old computer system unit. The main field of his activity is the control of heating elements in the furnace. At that time, I often had to leave for several days, including in the winter. Heating at home, the process is very inert - the first one and a half to two days after arrival had to freeze.Automatic control of electric heating inside the furnace, avoided this, with a reasonable consumption of electricity.

Since the control unit was located on the street - in the unfinished basement of the house, the case was insulated, and one of the channels was loaded with a small heater of several watts of five watt wire resistors in a rectangular ceramic case (arrow in the photo). They maintained inside the case a few degrees above zero. For switching the heater, a small contactor was used.

After some time, such a furnace mode was no longer necessary and the control unit was upgraded for use in. The case insulation was removed, the module was moved to one of the walls so that it was convenient to use from the outside. Contactor removed, powerful thyristor key for one channel added - heater control. The rest of the keys are made low-power, their load is small - fans and possibly additional illumination lamps (seedlings).

The control module is disassembled into separate boards, all of them are fixed on the same plane with the help of racks, so that it is convenient to use it from the outside - the screen is at the top, below it are buttons. Opposite the screen, of course, a rectangular opening was cut. Brass racks, with a flat end, were simply soldered to galvanized steel (it is well treated with “soldering acid” - zinc chloride). On the "motherboard", to increase reliability, the power connector and the sensor connection connector are removed. The leads from the mounting wire are soldered to their pads.

A metal circuit board with an installed thermostat is mounted on the front wall of the housing. Blind rivets.

The front panel is printed on a color printer and covered with a piece of plexiglass. In general, the design turned out to be "industrial", and it is not bad.

The thyristor key was assembled according to the scheme above. The advantages in comparison with the triac are the “diversity” of the key crystal in two cases - a significantly larger area of heat removal. The rest, see the diagram with the triac.

The thermostat module has been updated to version 1.9. This allowed us to use several more useful functions of the device, for example, it became most convenient to use analog sensors, a very useful ability appeared - the dependence on each other of different stages of the program. An alternative version of the control program for the computer is also attached to the new version, the most useful difference of which is the “data acquisition” mode — recording the temperature of the sensors in a file. Let me remind you that updates are distributed by the developer and are located at the links above.

Until the garden season, the thermostat was involved in ancillary work - loaded with an improvised “drying cabinet” from an old oven, for drying a photo varnish on blanks of printed circuit boards and other pieces of iron - the process involves a fairly accurate temperature range.