, with the help of the wizard, we examined the manufacture of a surfboard, in this we will figure out how to cover it and how to process it and what additional elements need to be installed.

Tools and materials indicated in the first part.

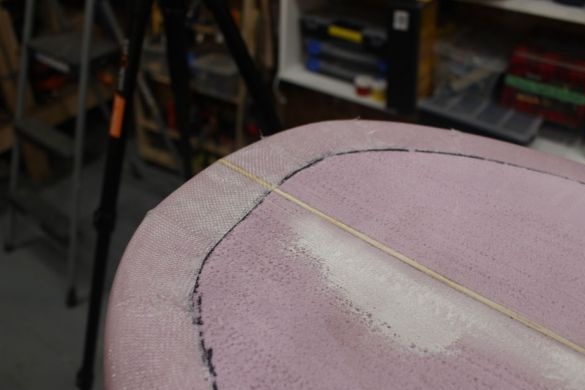

Step one: gluing the bottom with fiberglass

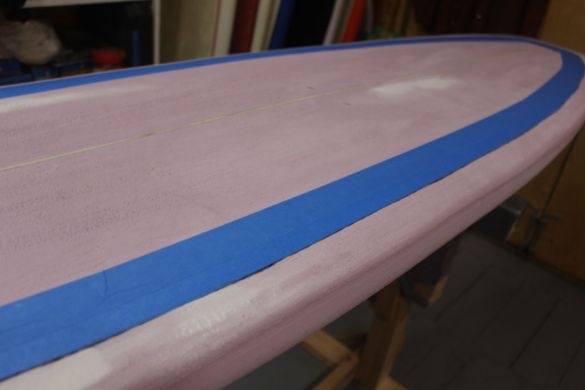

For better adhesion, grind the surface with a rough sandpaper with a grain of 40-60. For the bottom, the master uses fiberglass weighing 5.5 grams per 1 cm². There are two layers for the top. One 5, 5 g * 1 cm², the second 4 g * 1 cm².

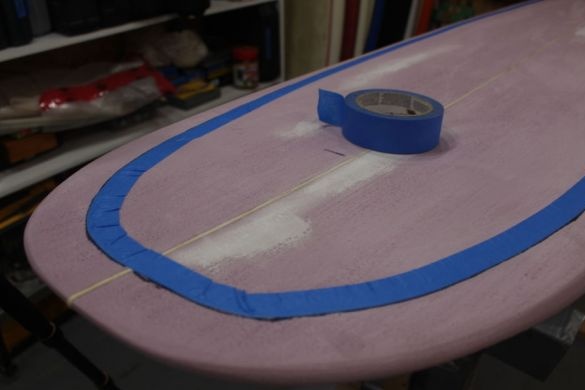

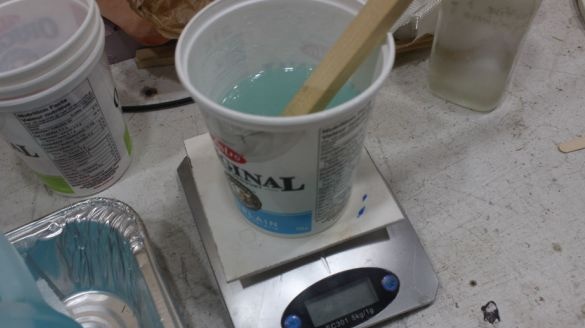

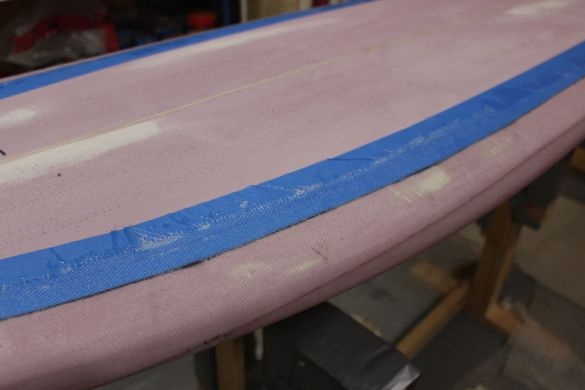

First glues fiberglass to the bottom of the board. Adhesive tape adheres to the edge of the deck. Cut fabric with launch on deck. It breeds epoxy resin. Adds the additive ADDITIVE F. If desired, pigment can be added. Apply resin to fiberglass. Smoothes, removes air bubbles. Removes tape. It glues another layer of fiberglass on the tail, in the place where the fins will be fixed.

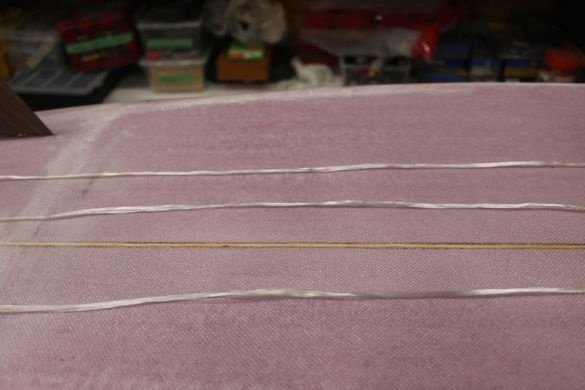

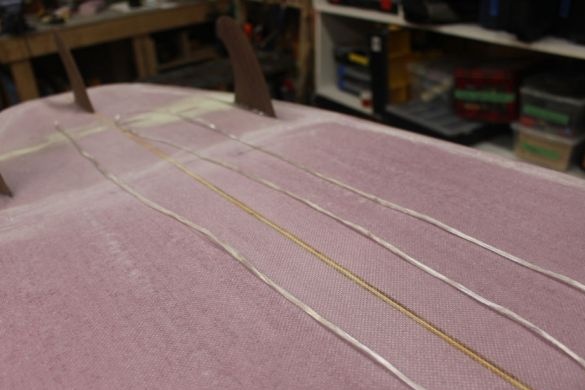

Step two: gluing fiberglass deck

Deco glues in the same way as the bottom. The only difference is that two layers of fiberglass are glued to the deck. Dry fabric is laid on the board in two layers and applies glue. Before laying the fabric, the edge of the glued fiberglass should be sanded. After drying the resin, polishes the edge.

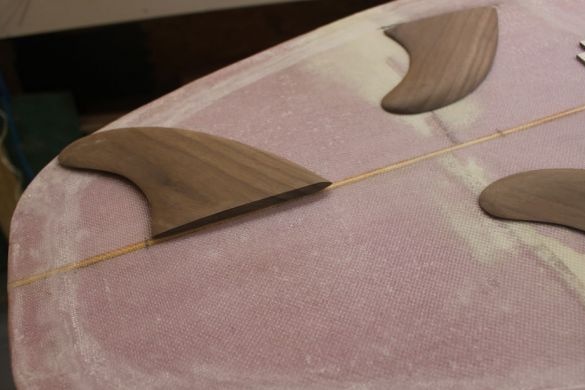

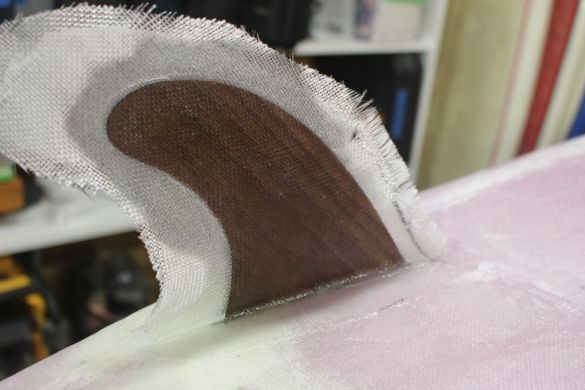

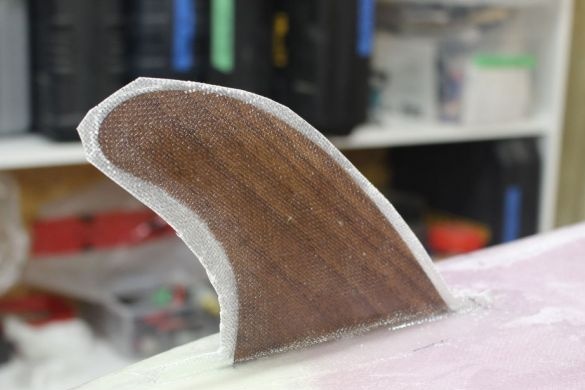

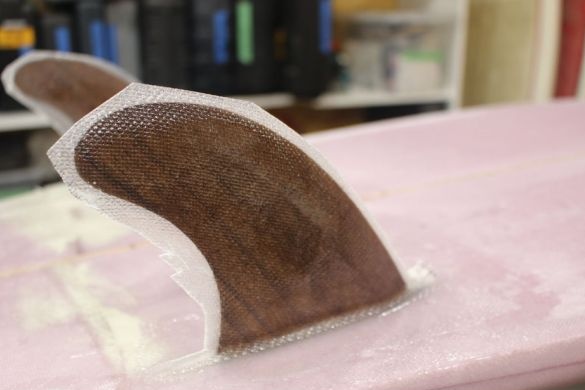

Step Three: Fins

The fins direct the movement of the board and largely determine the possibility of control over the board, how it rotates and how fast it moves.

Fins are removable and non-removable. The master will do non-removable. According to the removable fins, draws a template on the board. USMMko cuts out fins. Grinds. The inner part of the fin is smooth, the outer rounded.

The fins are set according to the preferences of the surfer. The speed and maneuverability depend on the installation angle. There are special templates for installation. Pastes fins with fiberglass and glues them to the installation sites. After solidification, grinds fins.

Step Four: Extra Resin

Next, you need to level the surface of the board. Pastes, with a protrusion, the edge of the board with masking tape. Knead the resin. Pours onto the surface of the board. Smoothes the resin with a brush over the surface.After 2-3 hours, removes the masking tape and leaves the board for a day. After a day he does the same operation, on the other hand.

Step Five: Grinding

Grinds the board.

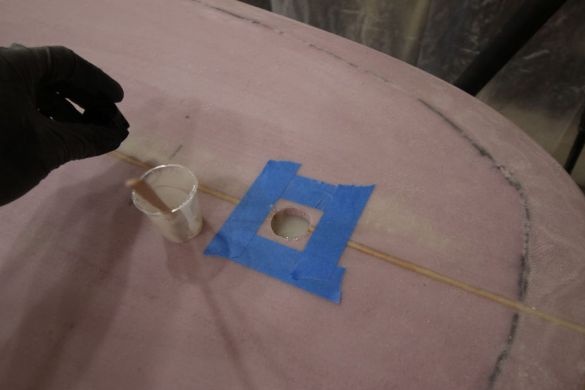

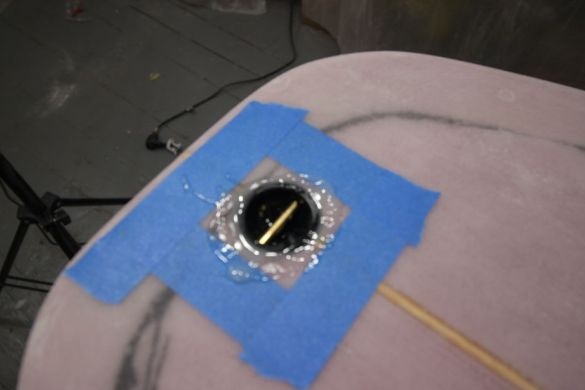

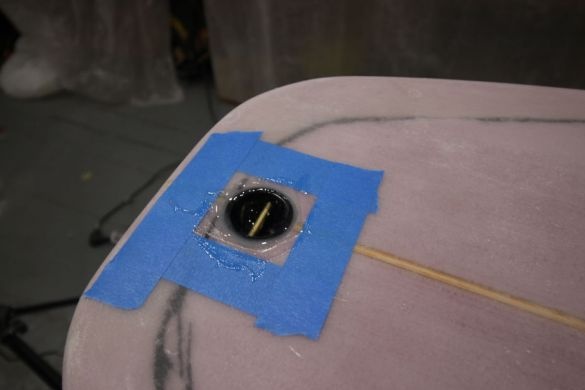

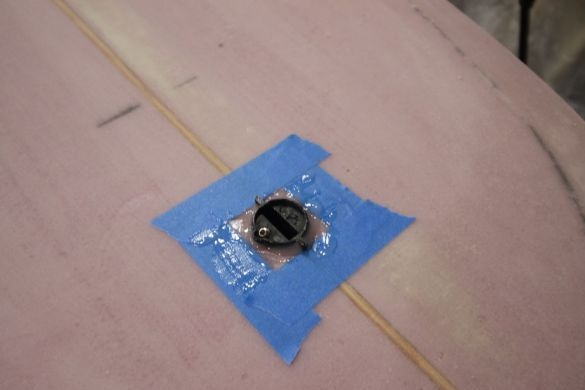

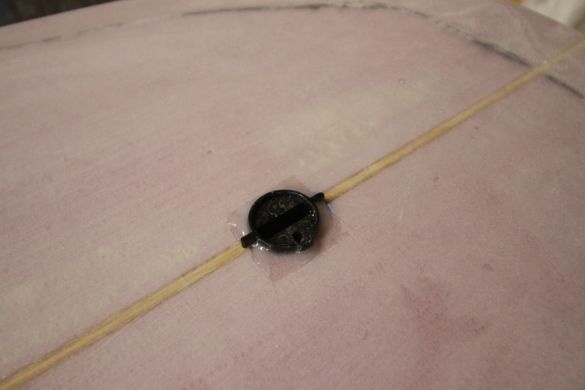

Step Six: Mount

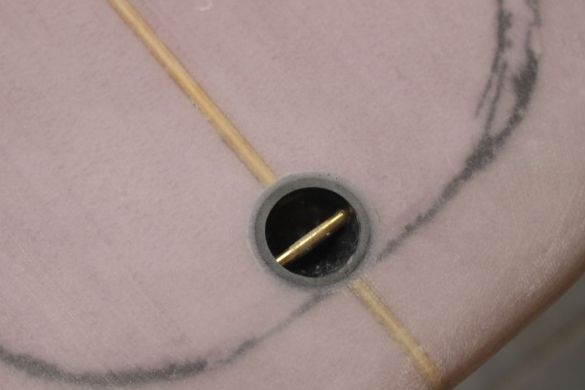

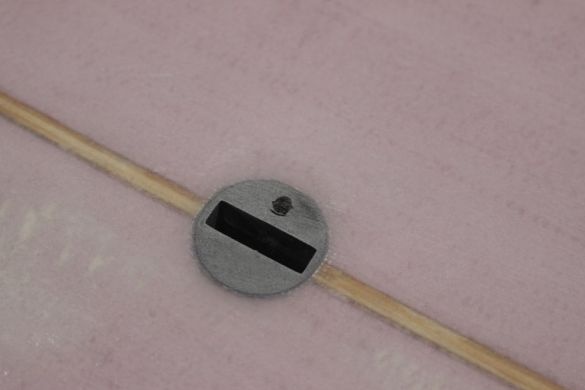

To install the Go Pro camera, the wizard installs the mount. Cut a hole in the board. Paste the mount. Grinds the surface.

Seventh step: painting

Degreases the surface of the board. Apply water-based paint. Sticks on the logo.

Step Eight: Final Grinding

After painting, another layer of epoxy is applied as described in step four.

After drying, the resin polishes the entire board. Sandpaper uses from 220 to 2000.

After polishing, it dyes a black line.

Surfboard ready. As you can see, manufacturing is complicated, but the result is excellent.

Link to the first part.