Often in life there is a need to get a voltage of 220V from a lower, say, 12 Volt. For example, you need to connect the charger from the laptop to the car battery, this is not a problem. In addition, inverters are widely used in alternative energy. Usually they are put on windmills, hydroelectric power plants and so on, which in most cases generate low voltage.

Today we will look at how to make an inverter do it yourself. There is no complicated electronics, the set of components is very small, and the scheme is clear to any beginner. All you need to do is connect a few resistors, transistors and a transformer. Intrigued? Then move on to learning the instructions!

Materials and tools used by the author:

Material List:

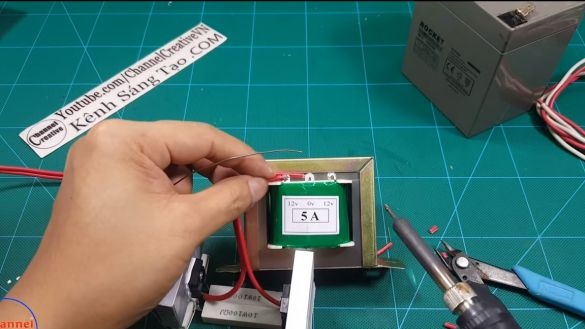

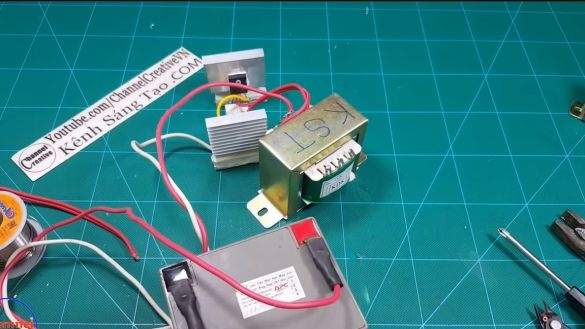

- transformer 12-0-12V at 5A;

- 12V battery;

- two aluminum radiators;

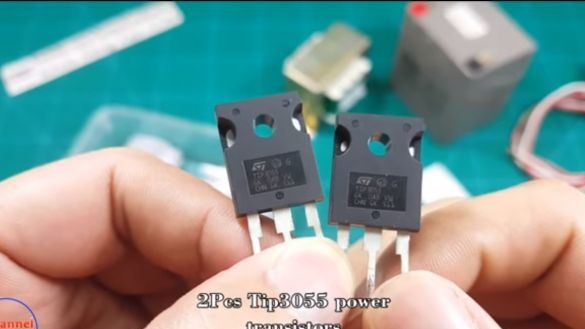

- two transistors TIP3055;

- two resistors 100 Ohm / 10 watts;

- two resistors 15 Ohms / 10 Watts;

- wires;

- plywood, laminate (or other for the manufacture of the body);

- socket;

- thermal grease;

- plastic ties;

- cogs with nuts, etc.

Tool List:

- soldering iron;

-

- ;

- nippers;

- a screwdriver.

Inverter manufacturing process:

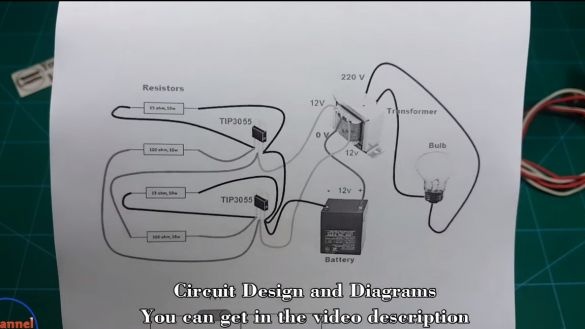

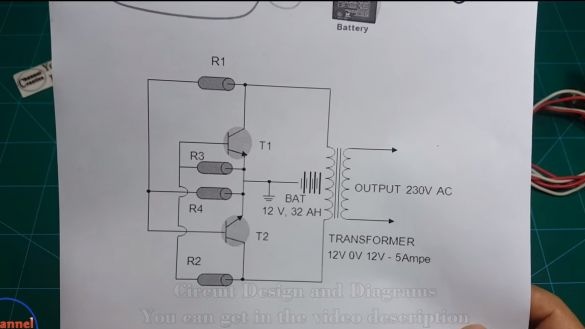

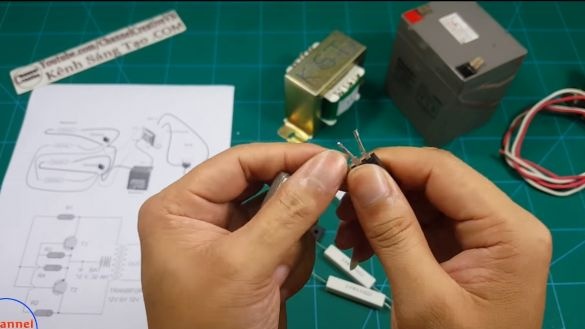

Step one. Check out the diagram

Check out the wiring diagram for all elements. There is how electronic a detailed diagram, as well as simple, intuitive, where and which wires to connect.

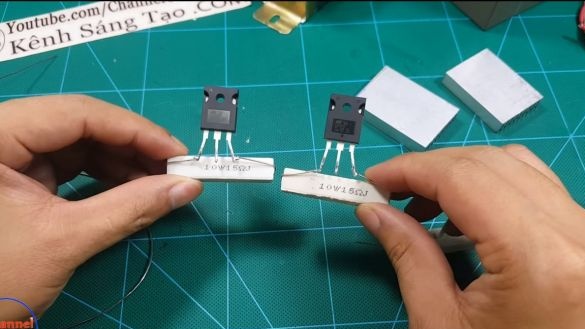

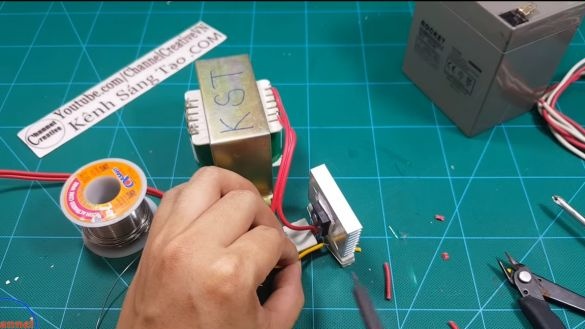

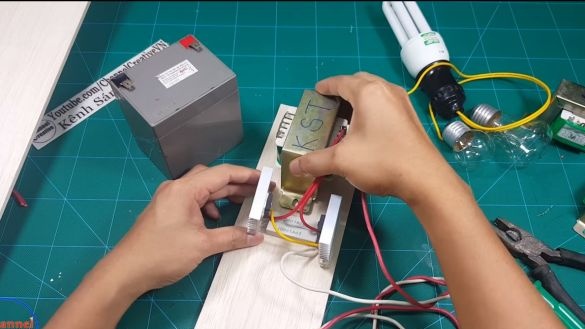

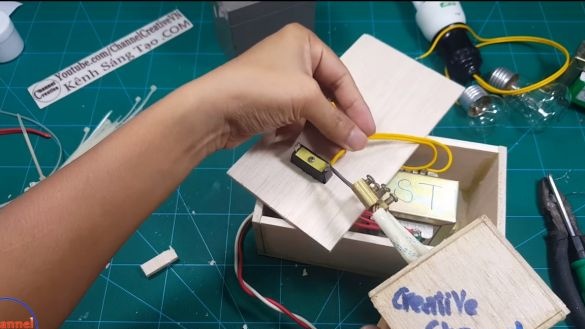

Step Two We collect two circuits from resistors and transistors

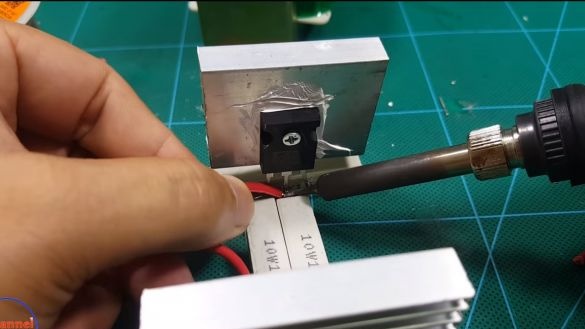

We take the transistor and attach it to the 15 ohm resistor, as seen in the photo. In the same way we fix the second transistor.

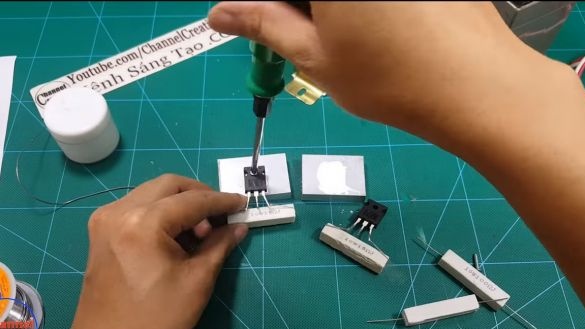

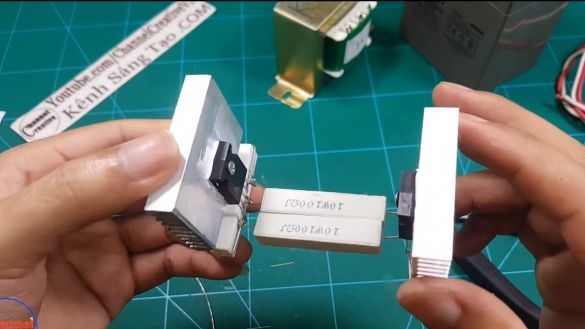

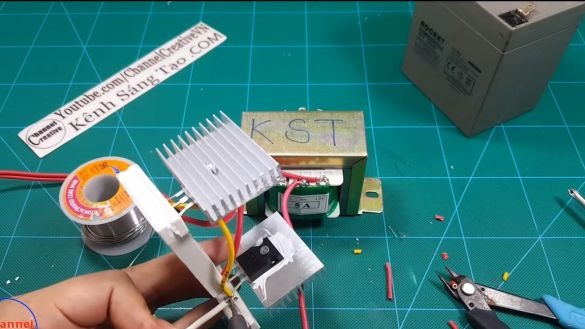

Step Three Radiator

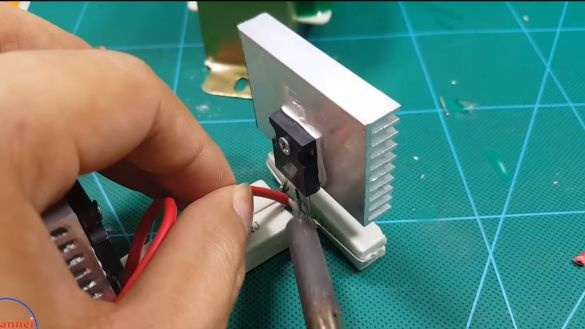

During operation, the transistors will warm up, and if this heat is not removed, they can fail. Here you will need two radiators. We drill holes, apply thermal paste and carefully attract the transistors to the radiators with self-tapping screws.

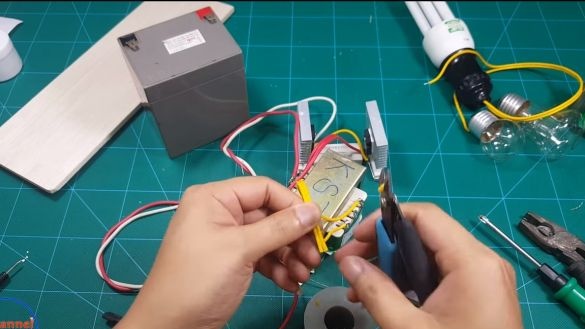

Step Four Connect two circuits with 100 ohm resistors

We take two 100 Ohm resistors and connect the two circuits diagonally. That is, you need to solder the contacts to the two extreme left legs of the transistors, if you look at their front part.

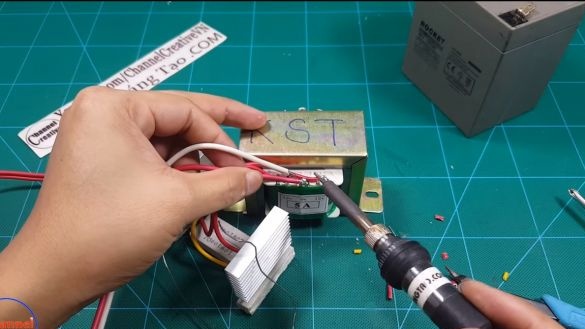

Step Five We connect the central paws

We take a two-wire wire cable and solder one wire to the central contacts of the transistors. Then these wires are soldered to the leftmost and rightmost contacts on the transformer, as seen in the photo.

Step Six Jumper

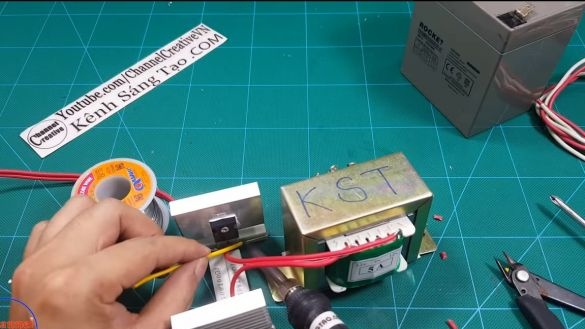

In accordance with the scheme, you need to install a jumper between the most extreme and right contacts of the transistors. Cut off a piece of wire and solder them to the paws.

Seventh step. Further connection

We take another piece of wire, it is pink from the author. Solder it to the central contact of the transformer, plus from the battery will be supplied to the transformer through it.

You will also need a piece of white wire, it will be minus from the battery, you need to solder it to the yellow wire, that is, the jumper installed earlier.

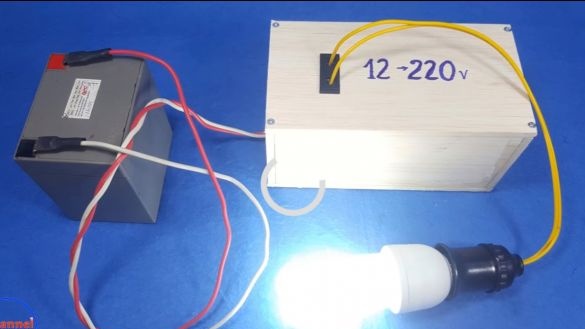

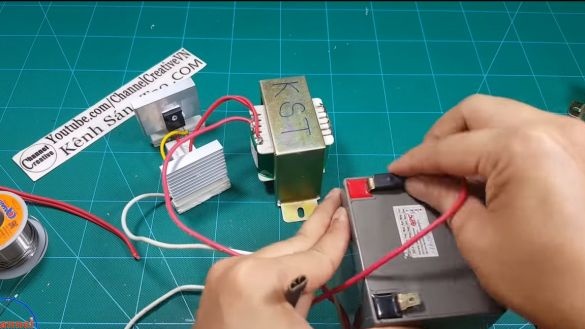

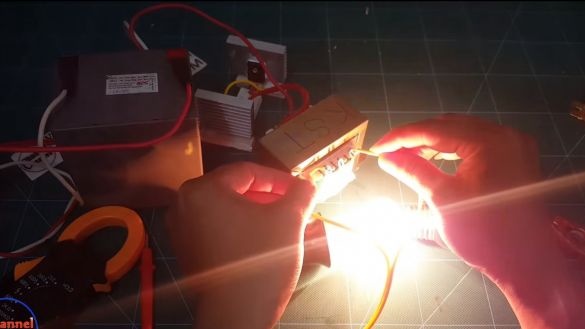

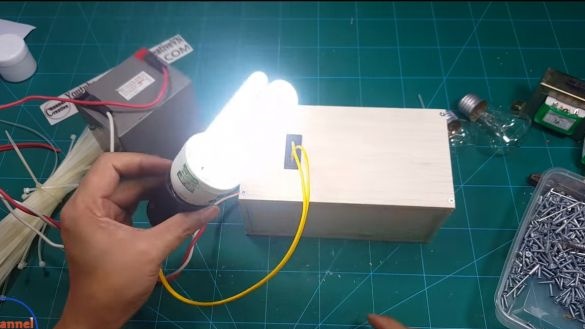

Step Eight. Testing!

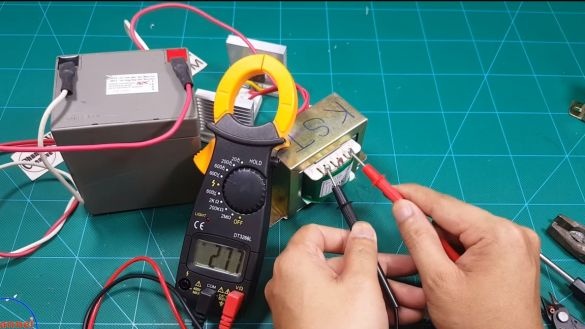

We didn’t have time to look around, as the electronic part of the inverter is assembled, you can test! We connect the battery and measure the voltage with a multimeter. It jumps in the range of 200-500V.

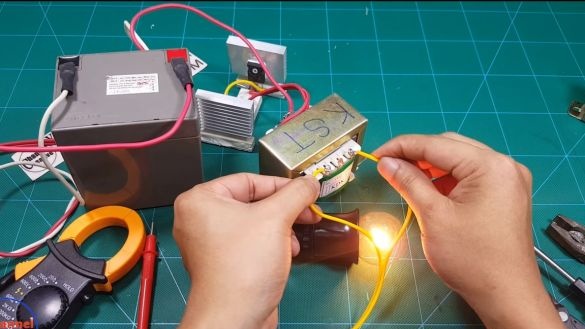

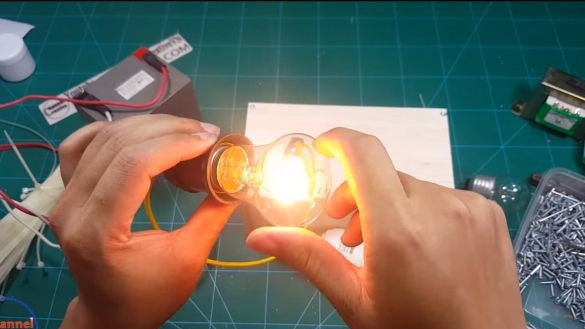

First, the author decided to connect a very weak 5-watt light bulb to the inverter, it caught fire without problems.

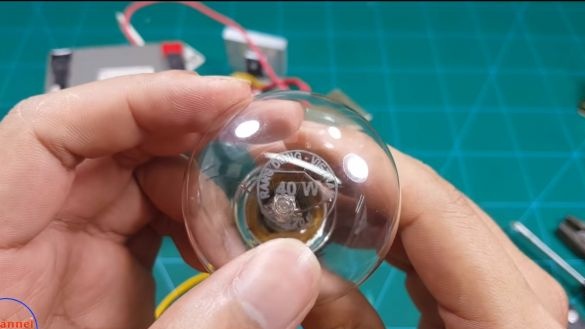

Then a more serious 40-watt bulb was connected, and it burns as if it was plugged into a power outlet at home, but actually it is powered by a small 12V battery.

In the end, the author decided to connect a 15-watt fluorescent lamp, it also caught fire without any problems.

It was also decided to try to connect charging for mobile. The phone charges without any ado.

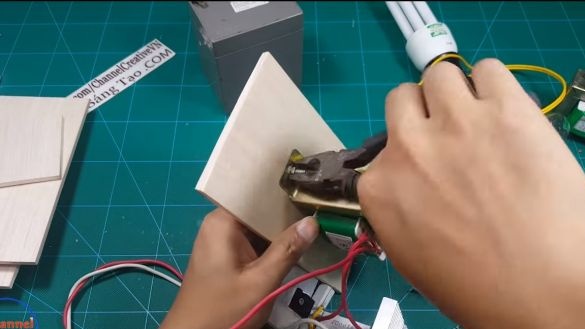

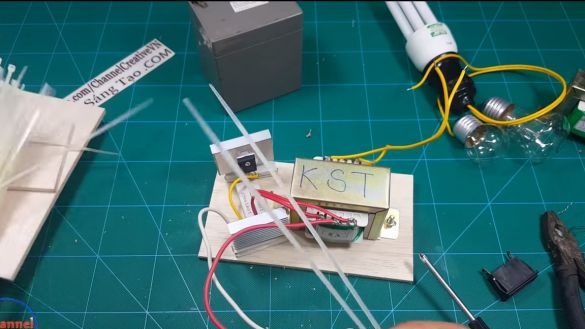

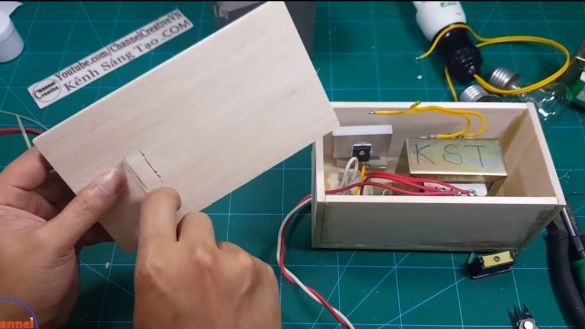

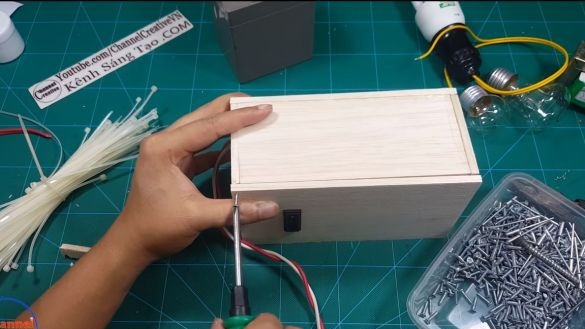

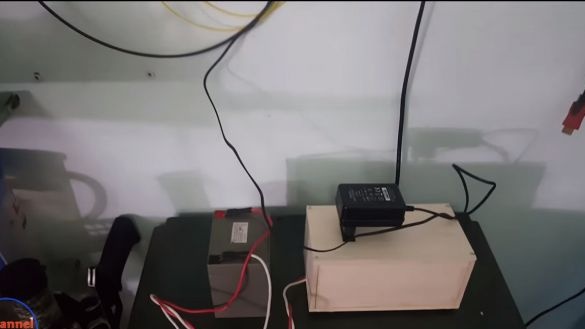

Step Nine. Putting the case together

To make everything safe and look aesthetically pleasing, we will make a housing for the inverter! To do this, you will need a socket, a piece of cable, as well as plywood, laminate or something similar. Cut the material to the desired pieces to make a box. We fasten the transformer to the base, for reliability, the author decided to fasten it with screws and nuts. As for the electronic part with transistors, it was decided to fix it with plastic ties. We drill holes and draw the lower resistors 100 Ohm to the base.

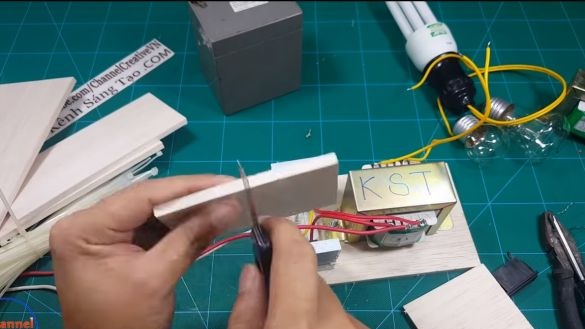

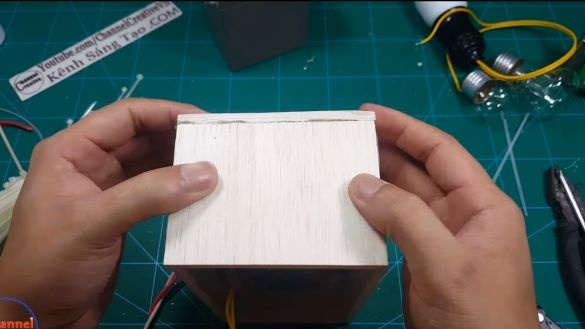

The case can be assembled, for these purposes the author used hot glue. As for the top cover, then you need to cut out a seat for it under the outlet. The author’s material is soft, he cuts the window with the help of an office knife. If the window is a suitable size, the outlet should lock in place. On the reverse side, it can be further strengthened with hot glue or epoxy.

It's time to install the cover, we fasten it on the screws to have access to the inside of the inverter.

Step Ten Final tests

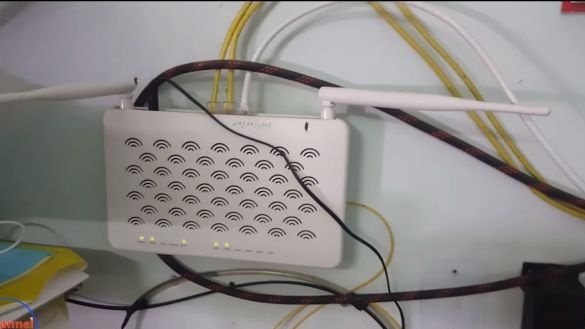

The inverter is ready, you can check! Light bulbs burn without difficulty, but what will happen to more serious electronics? The author tries to power the network router from his brainchild and it works without problems! Now you will not be left without WIFI, even if you turn off the lights.

That's all, good luck and take care! Do not forget during assembly that a voltage of 220V is generated, and this is life threatening!