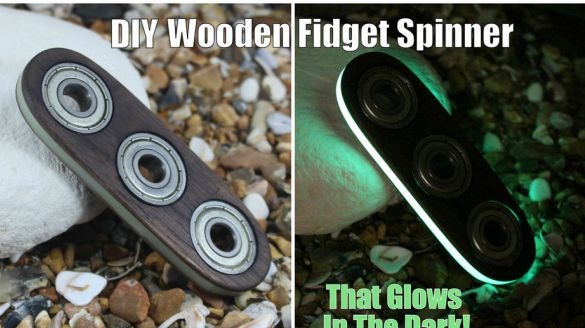

Hello. The article will tell and show about how to make a glowing spinner do it yourself!

Herself homemade will be made of walnut pieces, also of a simple bearing, which the author found at home and from mikarta - a multilayer material that is made of components such as fabric, glass wool, fiber, paper, carbon fiber, and plastic.

Part 1: Parts and Accessories

Bearings;

Fluorescent cyrinitis;

Feather drill 21 mm;

Band-saw;

Machine Tools: Lathe, Sanded, Drilling

Part 2: Preparing the blanks

First, the author will cut a walnut and kryptonite into small pieces with a band saw. Then he will polish the workpieces on the sides for good adhesion of the parts.

The width of the walnut blanks is 5 mm, and kryptonite is 3 mm.

Part 3: Connecting the parts

The author will demonstrate to you a "sandwich" of kryptonite and walnut, while he glues the pieces together with super glue.

After the author squeezed the pieces, he removed the excess glue with a paper towel so that the clamps would not stick to the tree!

Part 4: Planning the outcome

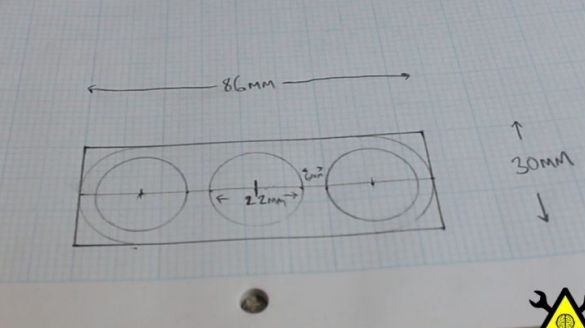

The author drew a template on graph paper and carried it glued blank

Part 5: bearing bore

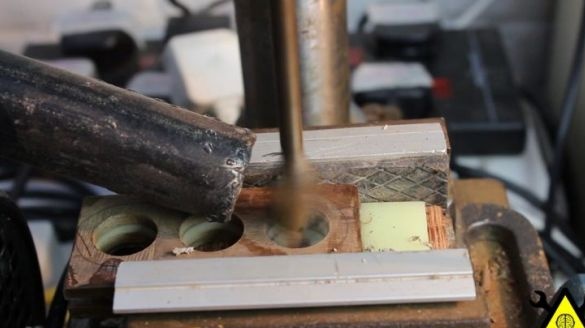

The author drilled a hole using a pen drill, the length of which is slightly less than the diameter of the bearings.

In the author’s case, we drill a fragment of a tree with a drill, at a later stage he removed the resulting damage.

Part 6: Processing

The author returned to the band saw and cut the blank in one shape.

Part 7: Selecting Holes

Holes at this stage have become slightly smaller than the diameter of the bearings, so the author will need to increase them to 22 mm.

Instead, the author took glue to fix the bearings, using friction. During

collections, the author needs to constantly monitor the size of the holes using a caliper.

When the length is close to 22 mm, the author will switch to sandpaper.

Part 8: Finishing

The author started polishing. Gradually, he increased the graininess. He also settled on sandpaper with a grain size of 12,000 units.

This allowed the author to make the surface of the spinner smooth to the touch and he removed traces of machining.

Part 9: Cleaning and Handling

To clean, he took ordinary medical alcohol, after which he applied oil to parts of wood.

The author took some oil and now the spinner will spin for a very long time.

Part 10:

Thank you for viewing and reading this article, all enjoy reading and using.