The compressor is a very convenient thing, this device helps out especially well when painting. First of all, painting with it quickly, and secondly, it is much better than painting with a brush, but everything, of course, depends on the equipment and skill. It is also convenient to pump automobile wheels with a compressor.

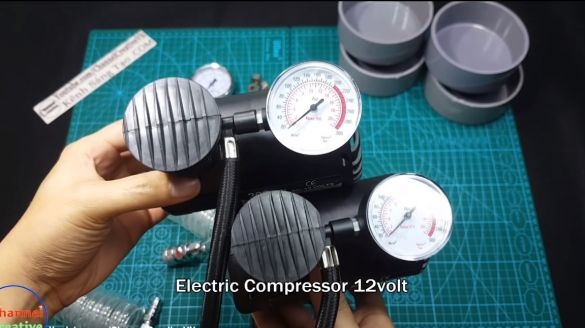

In this instruction, we will look at how to make a simple compressor with a receiver, which means that they can carry out paint work. For the manufacture of the receiver, the author used a size of 110. Automotive compressors for 12V were used as a pump, for greater efficiency, the author put them in two pieces. The main feature of such a device is that the compressor can operate on a 12V battery.

Materials and tools used by the author:

Material List:

- two compressors for 12V;

- two pieces of PVC pipe at 110;

- 4 caps to the pipe 110;

- air fittings:

- a piece of hose (for high pressure);

- metal clamps;

- hose and spray gun;

- pressure gauge;

- FUM tape;

- a piece of board;

- An old car camera with "nipples";

- wires;

- crane;

- glue for pipes;

- switch;

- steel plate;

- cogs with nuts, screws and other little things.

Tool List:

-

- scissors;

- screwdrivers, wrenches;

- a hacksaw for metal;

- roulette;

- marker;

- .

Compressor manufacturing process:

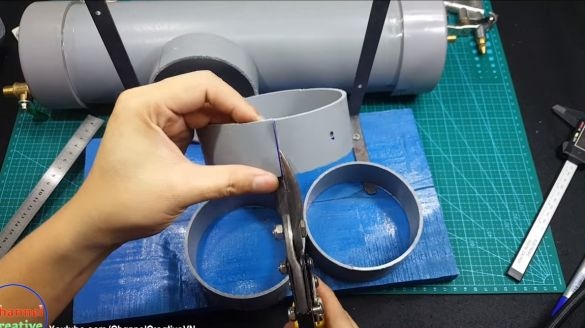

Step one. We prepare stubs

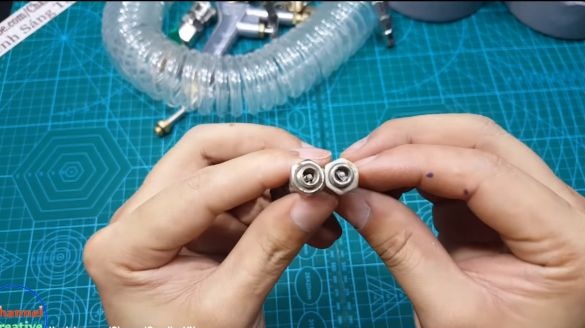

To assemble the structure you will need 4 plugs for pipes. They install all the necessary fittings for connection. The first thing we install is the fittings for connecting the pumps, we must have 2 jokes. The author cuts out these fittings from old automobile cameras. We take scissors and get the necessary parts. The point is that the gum remains on the fitting, which works as a stop.

In the plugs, drill holes and install fittings. We put the washers, and tighten the nuts carefully on top.

Now we proceed to install the pressure gauge. We drill a hole for it, and wind the FUM tape onto the thread. On the other hand, you need to put a rubber gasket that can be cut out of the car camera, and also take the washer, nut and tighten the whole thing.

You also need to install a crane, we will take air from it.

Now we take two more stubs, it is necessary to install one fitting in it. They will be needed in order to combine both containers using a piece of hose.

Step TwoWe collect the receiver

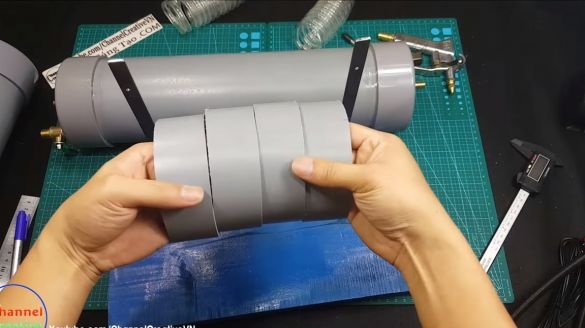

Cut two pieces of PVC pipe of the desired length, the larger this parameter, the more air the receiver can store. We glue the plugs using a good glue. The most important thing here is that the glue holds the plugs tightly and also does not let air through. For fidelity, it is better to screw the plugs with screws, so they just will not fly off in case of something.

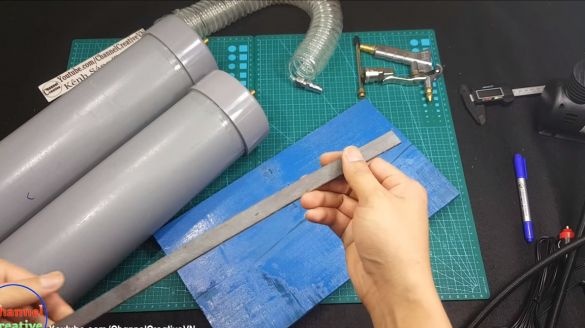

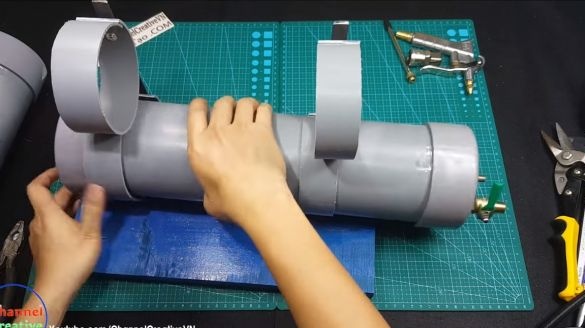

Step Three We prepare the base and install the receiver on it

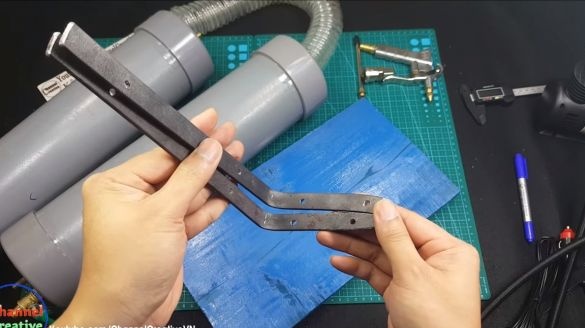

As a basis, the author uses a piece of a massive board, the base must be heavier for the device to stand reliably. Paint the tree so that it does not absorb moisture and looks beautiful. As fasteners you will need two steel plates. We bend them in the form of the letter "G" and drill holes.

How will we fix the pipes? Very simple, you will need 4 small pieces of 110 PVC pipe. Drill holes in them and then cut across. The result is excellent pipe clamps. We fasten them with screws and nuts to the plates, and then install the pipes.

At the end, you will need to connect a hose to combine both tanks. The hose must withstand high pressure. The author inserts one hose into another, and then clamps them on the fittings with the help of clamps.

Step Four Preparation and installation of compressors

The compressor, the author decided to use two pieces, they work synchronously. Everything will work on one pump, but one will pump air much more slowly. The author decided to disassemble the pumps and solder one common cable to them for simultaneous start-up. You will also need to install a switch in the circuit.

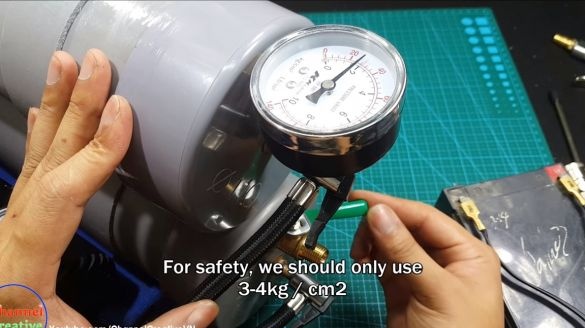

To fix the compressors, the author used double-sided adhesive tape, as well as a pair of self-tapping screws. After installing the compressors, connect their hoses to the receiver fittings. You can experience it! We turn on the pumps and monitor the pressure, it is not recommended to pump more than 3-4 atmospheres. Once you reach the desired pressure, the pumps can be turned off.

Step Five The final stage of assembly and testing

At the end, you need to connect a hose, as well as a spray gun or any other device. Use FUM tape on all threaded connections. We connect the battery, achieve the desired pressure and try to paint.

Homemade ready. The disadvantages of the design include the fact that during operation it is necessary to increase the pressure from time to time, since the receiver is small in volume. But we solve this problem, we can install a switch that will turn on the compressors when the pressure drops below a given value. In general, there is no limit to perfection. Good luck