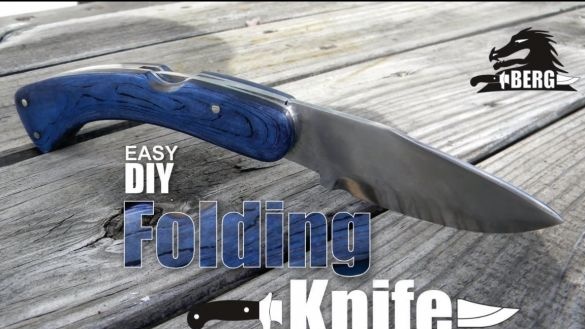

A folding knife is an excellent tool in a man’s pocket and not only. It must be taken with you when you go camping or just in nature. With a knife, you can not only cut sausage or open beer, but also protect yourself from enemies. And more often the enemy is not a person, but an animal, for example, a dog or even a fox. In this guide, we will look at how to make a nice simple folding knife. do it yourself.

To make a knife, the author used a pretty professional set of tools, he needed a jigsaw and other tools. But do not despair if you have skillful hands, such a knife can easily be made with ordinary hand tools. The locking device of the knife is also simple, all parts are made by hand. So let's get started.

Materials and tools used by the author:

Material List:

- high carbon steel (which can be hardened);

- pins (steel or brass is possible);

- material for linings (wood, plastic, and so on, optional);

- epoxy adhesive;

- spring rod (for the manufacture of the spring).

Tool List:

- ;

- a drilling machine or drill;

- clamps;

- grinder;

- vise;

- paper, pencil, scissors for making a template;

- sandpaper;

- oven, hardening oil.

The process of making a knife:

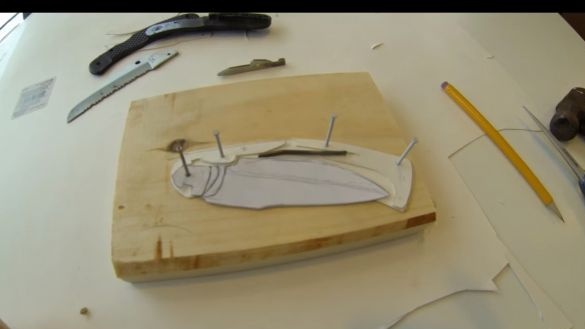

Step one. Template

First of all, the author makes a template, including all internal details. For those who have at least once made a knife, it will not be difficult to make such a template. You need to think through a locking mechanism, it is made in the form of a lever with a hook.

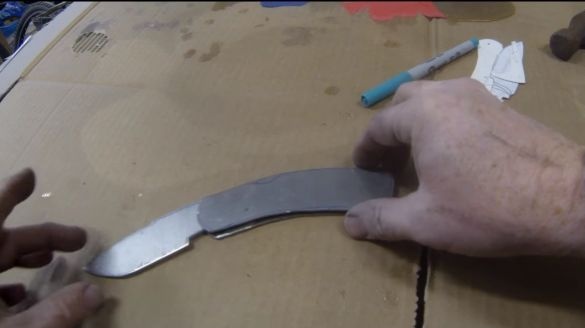

Step Two Cut the blanks

The author cuts out all the details of the knife from sheet steel. The locking mechanism consists of two parts, one part holds the spring, and the second is a lever with a hook that holds the blade.

To make a pen, you will need to grind two identical parts. All details, including the blade, the author cuts with a grinder. In hard-to-reach places where the grinder does not crawl, we make a lot of transverse cuts, and then gradually cut them out.

To make a blade, you need steel with a high carbon content, in America it is customary to use 1050 steel, in Russia 65X13 steel can be considered the most common steel grade for making knives. Good steel, which can be hardened, is widely used in the manufacture of tools. You can also use steel from an old cutting disc.

When you cut the blanks for making the handle, assemble them on pins or just on the bolts. Now grind the product along the contour, in the end you will get two identical parts.

At the same step, the author cuts the pads on the handle with an electric jigsaw, they will also need to be sanded together with the knife.

Step Three Grinding

We proceed to finer processing of the workpieces, namely, grinding. Here the belt sander will help us out perfectly. We bring the details to the ideal, and in the end we go through the file manually where we could not get the machine.

Using a grinder, you also need to remove the bevels on the blade. The author attaches the blade to a special device and proceeds to work. The main criterion here is the symmetry of the bevels.

In the end, the author processes the parts manually using sandpaper. The next step for us will be hardening, before that, do not forget to drill all the necessary holes in the workpieces, since then it will be problematic to do this.

Step Four We temper the blade

To keep your knife sharpening for a long time, the blade must be tempered. Since the blade is small in size, it can easily be heated to the desired temperature using a burner, as the author did. We heat metal until steel is no longer attracted by a magnet. If you approach this matter more professionally, then for each steel there is a clear heating temperature.

When you heat the steel, dip the workpiece into the oil. The used oil from the car, as well as vegetable oil, is quite suitable. After cooling the workpiece, go over the metal burner to burn the oil. Now steel can be checked if it is not taken with a file, which means that the quenching was successful.

The next step of quenching is necessarily the tempering of the metal, otherwise the steel will be very brittle. For holidays, a domestic oven is suitable. Place the blade in it and warm it for about an hour at a temperature of 200-250 degrees Celsius. Then let the oven cool when closed with the knife inside. Vacation done! Now the steel will spring, and the blade will not break under high load.

Step Five We proceed to the assembly of the knife

After hardening, grind the blade to a shine, because after heat treatment it will change color. Now the knife can be assembled. Lubricate all internal parts with engine oil so that the knife does not rust from the inside. Now we collect everything on the pins. Glue the lining with epoxy glue.

Grip the handle well with a few clamps and let the glue dry completely. Epoxy usually dries about a day.

When the glue is completely dry, we perform the final grinding. First, the product is processed on a grinder, and then manually using sandpaper. In conclusion, bring the handle to perfect smoothness with fine emery cloth.

If you used wood as overlays, then it must be protected from water. Soak the tree with linseed oil, or better Danish or the like. The oil will absorb into the tree and then dry. After oil impregnation, the pen can be polished, it will look very beautiful.

All that remains for you is to sharpen the knife well. For these purposes we use fine sandpaper dipped in water. Special ones are also suitable. fixtures for sharpening knives.

As a conclusion, the knife turned out to be excellent and durable. The author even opens it himself, if you suddenly wave your hand. If you protect the knife from dirt and water, it will last a very long time. That's all, good luck and take care!