The oxidation of iron is called rust. Oxidation of other metals - patina. The first fight. Chasing the second.

They are chasing not to expel, but rather to restrain. Coin collectors, for example, say that "patina on coins is the life experience of banknotes." The raid testifies to the antiquity of the exhibit, the respect for it by previous owners.

However, in addition to the natural patina formed by the interaction of the metal with the atmosphere and the environment, there is also an artificial one. The main purpose of the man-made film is decorative.

It is created using various acids and oxidizing agents. They are part of special mixtures.

On some metals the film is green, on others it is red, on others it is black. The tone of the raid also depends on the conditions in which the item was stored and operated.

On bronze statues standing on the streets of cities, the patina is greenish. But, there are metal figures, with a touch of other colors.

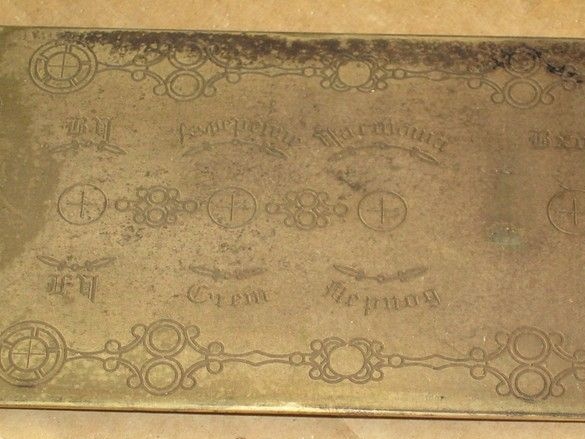

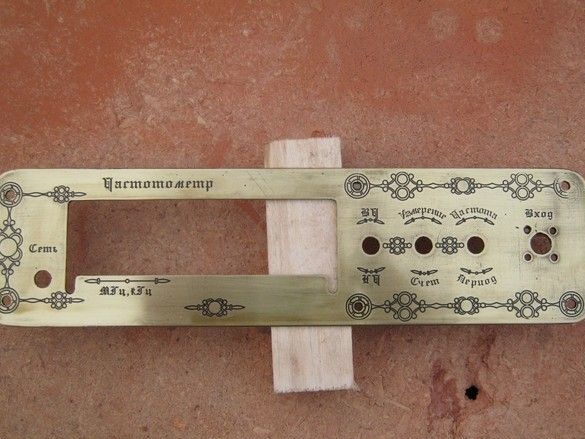

In the practice of a technical master, the need for patination often arises during the decorative etching of glands from copper and its alloys; these two techniques are practically inseparable. Indeed, having obtained a certain relief image by chemical etching, for greater contrast, it is necessary to fill the deepened areas of the piece of iron with dark. This allows you to see the picture from any angle and at any reasonable level of lighting. In addition, the finished piece of iron, after patination, acquires a spectacular look "antique". Given the simplicity of the process, neglecting such a decoration technique is simply unreasonable.

Compared to filling the recesses with paint, the artificial patina has several advantages - this also reduces the toxicity of fumes and, in most cases, the greater film strength.

The process is really simple, you just need to stock up on the necessary simple reagents.

Patinationing itself looks something like this - with an etched gland, a layer of protective varnish is washed off with a solvent (acetone). All the gland is patinated and covered with a dark layer. After drying, it is carefully ground with a “null” sandpaper, while the patina layer on the surface of the workpiece is sanded, and the patina in the recesses remains intact. The pattern "appears" in all its glory.After, it is desirable to polish the surface with a piece of felt with GOI paste and cover it with nitro or acrylic varnish. And you can enjoy squinting with pleasure.

It can be a scale of a device or device, a dial, a tag, a nameplate, a decorative panel or an overlay on the case. All this makes our finished device unique, and I dare to hope that it is beautiful, or at least, pretty.

What was used in the work.

Instruments.

Actually, a certain measured capacity, the capacity of which it is not a pity to throw out, larger, for sintering the sulfuric liver, for a small amount, a can, a portable gas burner for the same sintering is well suited. Capacity for patination. For "patination" with a coffee solution, you need a gas burner for soldering.

Materials

Access to water (dissolution, washing), necessary chemicals, solvent, rags, GOI paste, cloth or piece of felt. Nitrolac.

Well, let's move on to recipes patinating solutions.

The method spied on by steampunkers - blackening a saturated solution of instant coffee. Strictly speaking, the method is not entirely chemical - the reaction does not occur, but a layer of dark soot-like substance is formed, which tightly flows into the pits and recesses of the workpiece.

So, more details. A saturated solution of instant coffee is prepared in warm water. Brought to the consistency of the syrup. Then, the etched blank of our piece of iron is smeared with this paste, from the side of the drawing, it is clear.

You can brush, you can just use your finger, in small circular motions, that way, rubbing coffee paste into all the recesses. Then, without drying, we burn the workpiece in the flame of a gas burner.

Here, it is important to more or less accurately withstand the temperature. It should be such that the workpiece almost begins to glow. Exactly. At the same time, coffee paste on the surface turns into ashes and soot, but still does not have time in the recesses. If you don’t warm it up, the coffee on the surface will not burn out and looks like sticky hard-to-rub dirty.

After cooling the workpiece, the surface is ground by “nulling” and polished, varnished.

It is best to heat it with a gas burner, I tried to put the workpiece on burning coals - heating is too fast, it is difficult to control. An extra moment and everything burned out.

Yes, sometimes blackening in the recesses, for some reason, turned out to be not black, but gray. After coating with nitro-varnish, the filling darkens and becomes charcoal-black.

The “patination” method is a miracle as good - blackening comes out very dense and contrasting, the reagents are simple and accessible, the “patina” is not afraid of nitrol varnish - you can blink a brush without special ceremonies. However, in some cases, a method requiring strong heating of the workpiece is not applicable - for example, a large and / or thin workpiece (possible warping) or inseparable melting or burning parts. In this case, we turn to traditional, chemical patination. Yes, chemical patination, in addition, looks more “authentic”, more like a natural patina, so appreciated by antique lovers.

I will bring several recipe solutions for artificial patina from available components.

- Sulfuric ointment

Colors: Light brown to black.

Sulfur ointment is applied in a small amount to the workpiece and rubbed in a circular motion until the desired patina color is achieved. In the open air, the patination process is fast enough and some copper alloys instantly get a black tint. Such a patina is unstable and subsequently easily erased by fingers. It is recommended to apply the ointment to the workpiece completely immersed in water, pre-lubricating it with petroleum jelly or vegetable oil. Then the patina lies more evenly and less intensely.

If, during the patination process, the workpiece or its section has received an excessively black color, it can be washed off by households. soap under running warm water.

- Golden brown with a weak raspberry tint and moderate gloss patina obtained using a solution of the following composition, g / l:

Copper sulfate CuSO4 • 5H2O ________________________ 20

Potassium permanganate KMnO4 ____________________________ 5

A solution of room temperature is applied with a brush to the prepared surface of the product, after a day it is washed with hot water, dried and the operation is repeated 3-4 more times. Upon completion of the formation of the film, the surface is polished with a dry cloth. The same result can be obtained by holding the product in a solution of the given composition for 4-5 minutes (subsequent processing is the same). When immersed in this solution, heated to 95-99 ° C, a uniform dark brown film forms on the surface of copper and copper alloys.

- To obtain a patina from light to dark brown, use a solution of the following composition, g / l:

Potassium permanganate KMnO4 ____________________________ 20

Sulfuric acid (density 1.84 g / cm3) ___________________ 7

A solution of room temperature is applied to the surface of the exhibit; after drying, the surface is washed with hot water and dried. Processing can be repeated 2-3 times to obtain a uniform and dense layer of patina. The film must be sealed by polishing with a dry cloth or bristle brush.

- Patina of a beautiful, olive-brown shade, can be obtained using copper chloride solution (HOM). . This substance is used as fertilizer and is sold in the relevant departments of stores under the abbreviated name HOM. A popular and widespread fertilizer.

In ~ 600 ml of water, two tablespoons with a slide, chloroxide. After dissolution, pour 100 ml of ammonia, pharmacy. For a more uniform result, it is advised to stir the solution, or hang the product on a wire and chat with it in the solution. If the product was overexposed in the solution and it turned completely black, then it can be returned to its original state with the solution of Trilon B. Just keep in mind that Trilon corrodes zinc faster than copper, so the surface will become a little more porous and susceptible to further coating.

- for patination of copper, you can use sodium thiosulfate in ampoules, which is on sale in almost all pharmacies.

And finally, the classics of the genre - "Sulfuric liver". A simple, fast and convenient reagent for applying a durable, beautiful patina. It is well stored in a dry form, components for manufacturing are easily accessible and not expensive. The only negative is to cook it (the liver from the word “oven”) should be in the open air.

So.

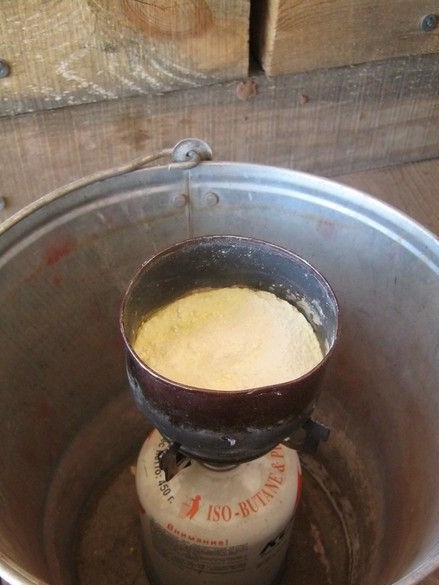

To prepare the sulfur liver, you need to mix one part of the powdered sulfur with two parts of potash in a can and put on fire. After a few minutes, the powder will melt, darken and begin to sinter, gradually acquiring a dark brown color. During sintering, sulfur fumes can catch a faint blue-green flame. Do not shoot down the flame, it will not worsen the quality of the sulfur liver. After about 15 minutes, stop sintering.

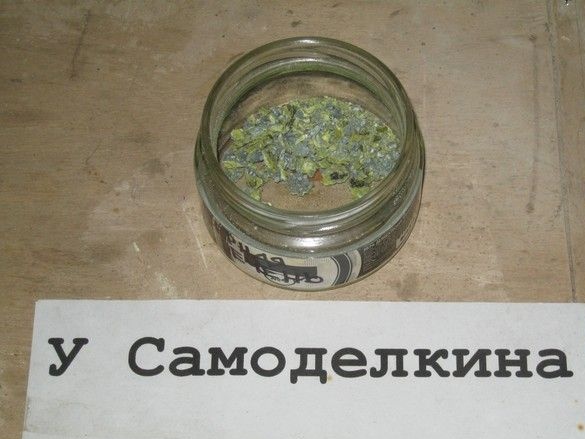

For long-term storage, crush the sulfuric liver into powder and fill it in a glass jar with a tight lid. When preparing a solution in one liter of water, add 10–20 g of sulfur liver powder. The patina obtained on metal in a solution of sulfuric liver is durable and beautiful.

Sulfur is not difficult to get in the hardware store, the store "Garden" and the like. It is presented as an additive to animal feed. You can also ask in pharmacies that have a drug preparation department.

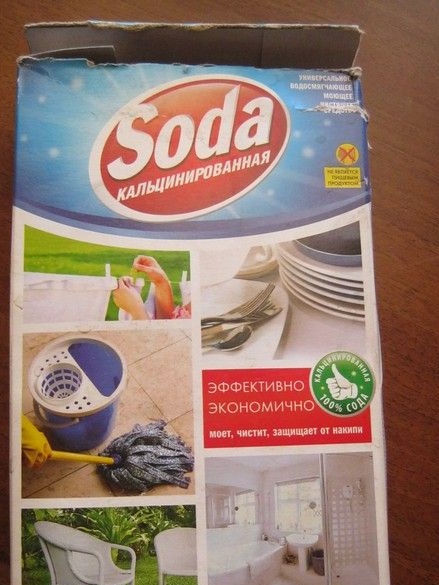

Potash is potassium carbonate (K2CO3), now it is not so easy to obtain, but there is a quite acceptable substitute. Soda ash (Na2CO3). Perfectly suitable - also alkaline metal, the same acid residue and the same amount. You won’t have to recount anything. Sold in hardware stores, next to laundry detergents.

We measure out the components, mix thoroughly. For a more accurate "dosing", the slide at the spoon should be removed with a stick.

For sintering, you will have to sacrifice a can. He warmed himself on a tourist gas stove, put it all in a bucket, so that it would not blow out much with the wind.

The process is going on, not smoke is emitted, but sulfur dioxide gas. God forbid, breathe in - eyes pop out on the forehead, so stay away from the windward side, approach, holding your breath.

Everything seemed to react, turn off the heat, let cool.

We pick out what we pick out, pour the pieces into a jar with a wide neck and a tight lid, we will certainly sign it.

An aqueous solution of sulfuric liver should be heated to ~ 60 ° C before patinating.