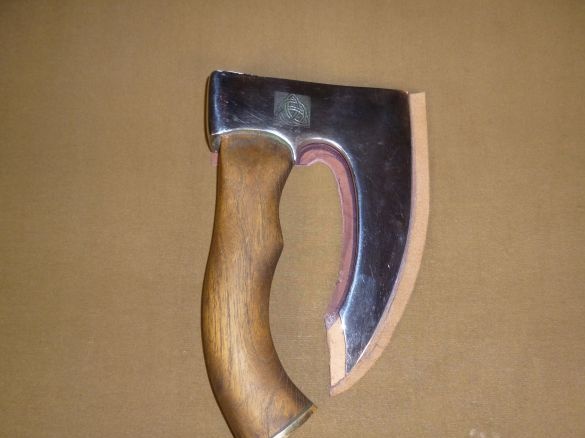

Greetings to all lovers of crafting something do it yourself. As they say, a knife without a sheath is the floor of a knife. For a tourist, an ax without a cover is the floor of an ax. Let's make a simple leather case for our homemade hatchet.

Tools needed and fixtures.

1. Electric drill on a rack.

2. Vise.

3. Scissors.

4. The hammer.

5. Two balls from the bearing.

6. Iron.

7. Pliers.

Donors and supplies.

1. Shafts from old boots.

2. Harness.

3. Rivets.

4. Copper tube.

5. Leather lace.

6. Water resistant adhesive.

7. Paint for the skin.

8. A piece of plastic from siding.

Everyone knows that knife scabbards and similar products are best made from shabrack, but since we don’t have it, we use the bootlegs from old boots.

We mark the contours of the cover on the skin, circling the ax blade with a pencil and making allowances of about 1 cm.

We cut out two pairs of such details. Details should be paired, two left and two right.

Unfortunately, the skin on the shafts is very soft. To give it sufficient hardness, we glue a plastic siding insert between the skin layers. We align the plastic, smoothing it with a heated iron through a rag and cut out the liner to the size of the ax blade.

We coat the parts with waterproof glue, put them together without forgetting about the liner. Clamp for a day in a vice between two planks. After a day, we get two dense blanks for the cover.

So that the ax blade does not cut the threads on the seam, glue a strip of dense leather onto one of the blanks, for example from a belt or sword belt.

We will make a suspension and a fastener from the same sword belt.

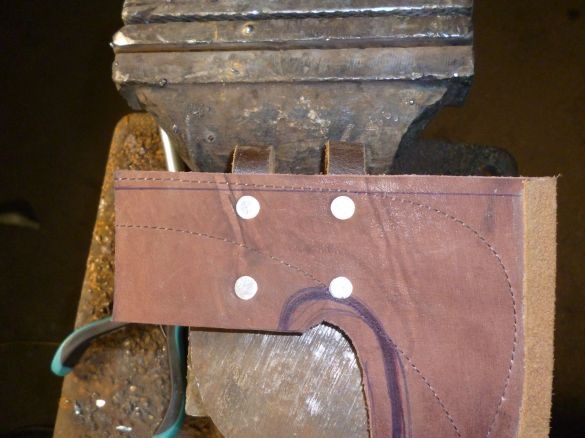

We glue the segments of the belt on the bottom of the cover, wait until it dries, drill holes and put two rivets.

We measure the desired size of the suspension, wrap the belts and drill holes in the same way and set rivets.

We mount the fastener in the same way.

We glue the parts together, smearing with glue only the leather insert between them. Clamp in a vice and wait a day. In places of the greatest load we install eyelets. The holes in the skin for the eyelets are best drilled with a metal tube of suitable diameter.

From the copper tube we cut off segments 1.5 mm longer than the thickness of the cover. We process the edges and clamp in a vice, setting the balls from the bearing at the ends. Slowly we reduce the jaws of the vice, the balls flare the edges of the tubes and we get a grommet.

We mark and drill holes for lacing. For precise marking, you can use a fork.

Stitch the edge of the cover with a leather cord. The cord can be cut from thin leather, we pulled from an ancient wicker belt. We pass the wire or shoe awl through the holes and stretch the cord, nothing complicated.

We cover the worn, old skin with paint and it again looks like new, we also install the second part of the fastener.

The cover is ready. Now the ax can be safely put in a backpack or hung on a belt during a hike or fishing.

Good luck to all.

You can watch the video on making the case here.