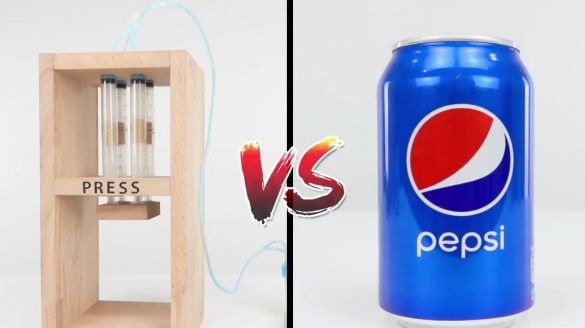

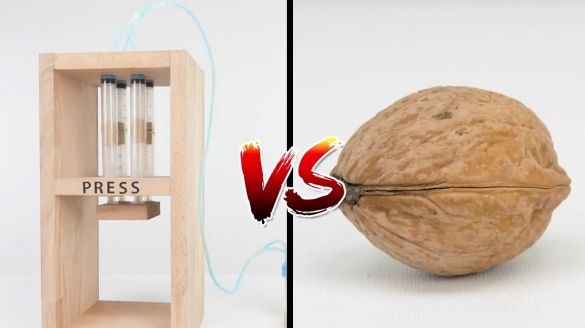

Good day to all! In today's article, I would like to share with you a very interesting and possibly useful to someone homemade, namely today's article will be devoted to the hydraulic press do it yourself! This press, although very simple and does not have any electronics, but it is still very effective. Having small dimensions it can be used in everyday life for your needs. For example, this press can calmly chop a walnut or squeeze an aluminum can. Homemade is very interesting so we will not pull.

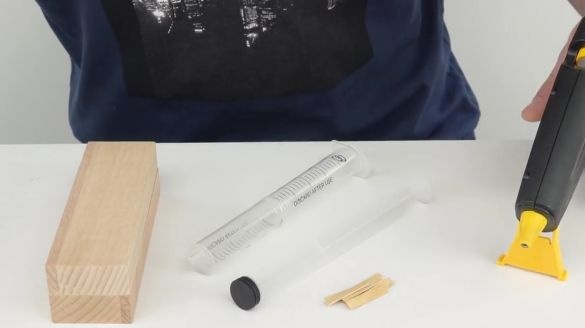

And so just a hydraulic press is needed:

- flat wooden boards, 2-3 cm thick

dropper

- three splitter for dropper

-two small tubes

-6 syringes

double for dropper

ice cream sticks

bolts

From the tools you will also need:

thermal glue

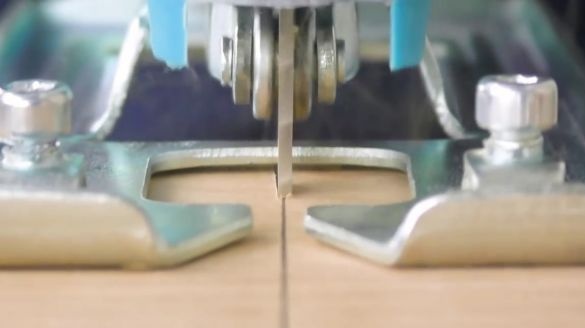

-electro jigsaw

-stationery knife

-Scotch

hexagon

-electric drill

And so the first thing is to do the marking on the board so that it turns out 3 squares of 15 cm on each side and 2 rectangles with sides of 38 cm and 15 cm. After it we take a jigsaw and cut out the blanks as follows:

Take an electric drill and use a drill for your screws or screws to drill 18 holes at a distance of 3.5 mm in general, as shown in the photo:

Now we change the ordinary drill to a feather drill and make 8 through holes as shown in the photo:

We begin the assembly of the structure.

To do this, with the help of self-tapping screws we fasten two long and one square planks as follows:

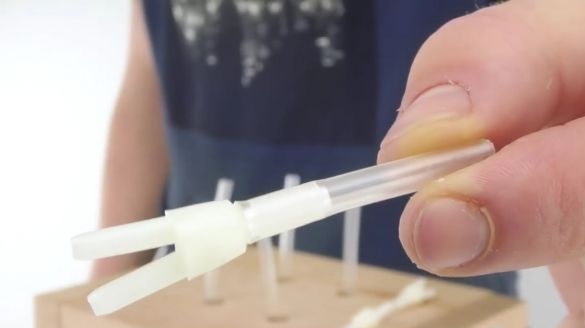

We take two syringes and one with the help of a clerical knife cut off the front part, and the second back part:

We connect both syringes with adhesive tape, you can strengthen the whole thing with cold welding or super glue, the main thing is to be tight and tight:

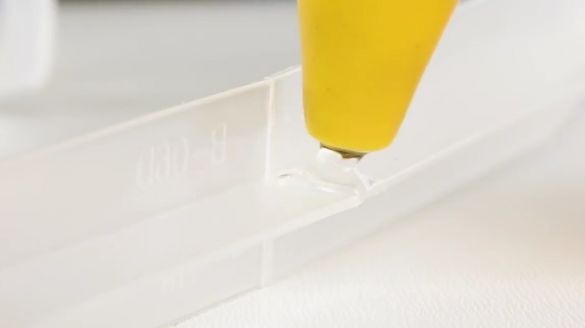

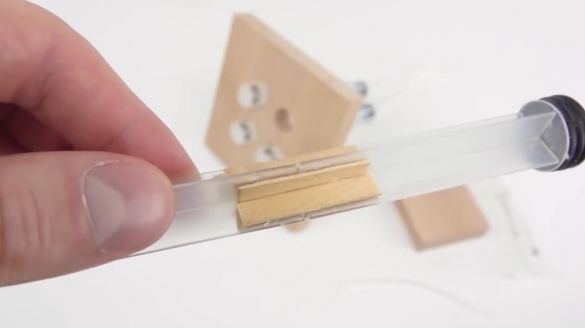

Now, for the “mega” syringe, you need to make the piston in a similar way: for one we cut off the front part, and for the second one the back, we connect both halves using thermal glue and we strengthen the connection point with ice cream sticks:

We are testing. Tightness is very important!

We take a tube from a dropper and cut a length of 10 cm from it, then put it on the “nose” of the mega syringe:

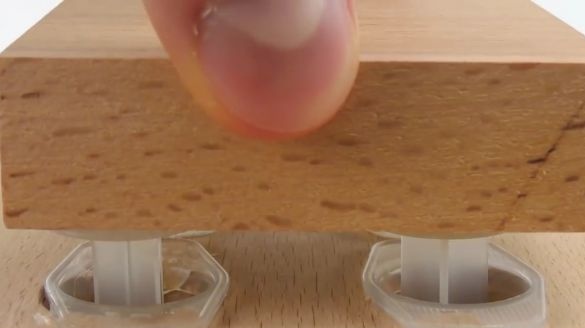

In total, you need to make 4 such blanks, after which we insert them into a square plate with the largest holes:

We apply thermal glue to the pistons and glue a small block on them as evenly as possible, thereby obtaining a single large piston which will act as a pressure piston:

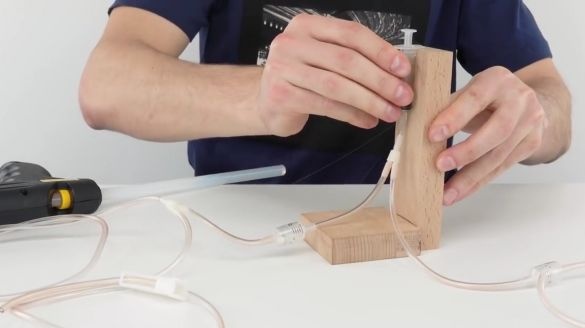

Take another square plate and insert the “mega” piston with thin tubes into it like this:

Then we insert it into the previous workpiece, so that the holes for the self-tapping screws coincide, insert the already mentioned self-tapping screws into the holes and twist with the hexagon:

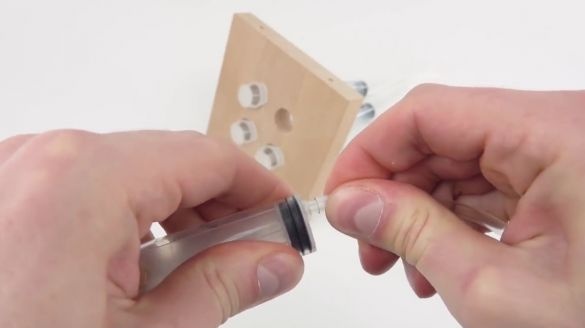

Now you need to take two splitters for the dropper and put them on as shown in the photo:

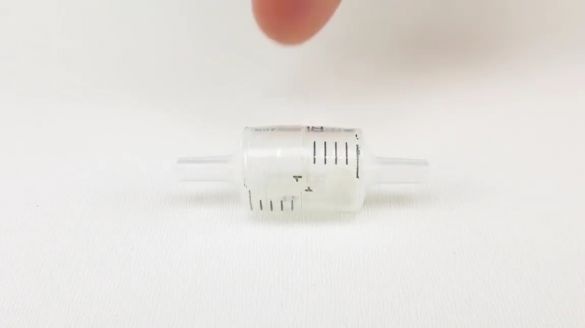

Then you need to make two valves:

We take a small bead of such a size that it is slightly larger than the diameter of the "nose" of the syringe, after which we take the remaining front parts of the syringes and glue them in place as shown in the photo, placing the bead in advance:

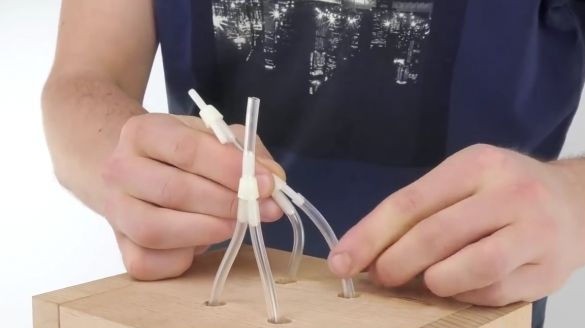

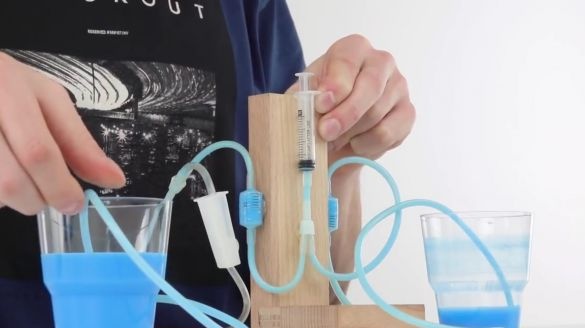

Now you need to collect all the hydraulics, for this we connect the dropper with valves and a syringe through the splitter in this way:

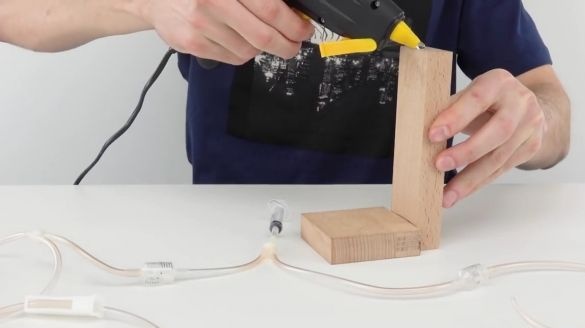

We take two small cubes and glue them as shown in the photo:

Glue the syringe with the piston up, as even as possible:

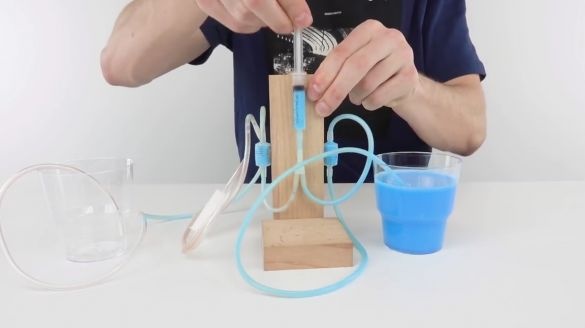

Now we take a glass with ordinary water and paint it in the color that you like, the author of the video painted in blue, as for me this color looks best:

We lower one end of the hydraulics into a glass with colored water, and the second end into an empty glass:

We fill the whole structure with water using a syringe, the glass which at the beginning was empty should be filled, after filling it is necessary to pour the liquid back into the first glass:

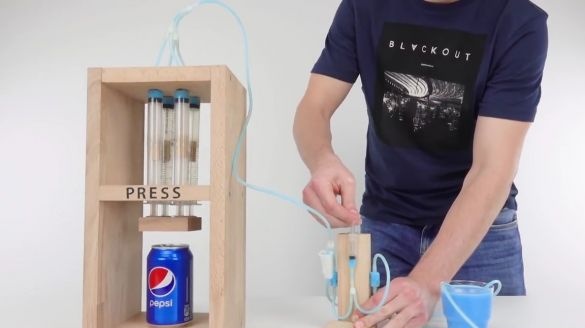

We take both designs and connect the tubes from the droppers with the same splitters, it should turn out as shown in the photo, after that you can decorate the press by signing it:

That's it! A homemade mini hydraulic press is ready and it remains only to test it, for this we put, for example, a nut under the piston and start pumping water with a small syringe into the mega piston, while it starts to move and squeezes the nut. Then we simply push the piston back and get the nut out. Also, this press can calmly crush an aluminum can from under soda. You can experiment with other objects and even calculate its power and pressure on the subject of the main piston.

I think you can increase the power of the press by increasing the number of "mega" syringes or by increasing the volume of these same syringes.

Here is a detailed video from the author on the assembly and tested of this homemade product:

Well, thank you all for your attention!