A couple of times, having disassembled the iPad and marveled at the generosity of the Yabloko on the cogs, I thought about acquiring a MINI electric screwdriver.

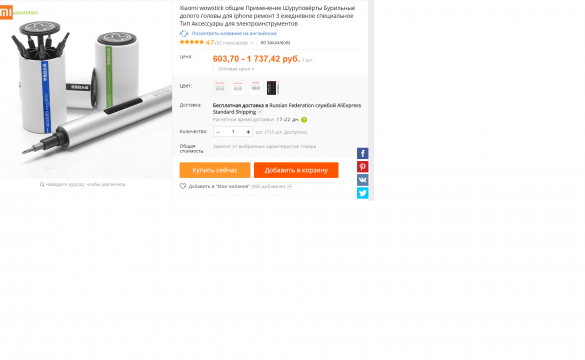

A quick search on the Internet networks yielded a result

Here she is a star of captivating happiness ...

But the awakening PLUSHKIN cooled the ardor by rising with a feeble chest between me and DREAM

The minimum price tag for the Chinese starts from 1800, the need for a device once a week (maximum)

Toad connected to the plushkin, the one that was sleeping on her chest,

In two creaky voices, they began to exhort and dissuade from such an unreasonable waste of money

- Do you really need a backlight, your lamp is off, or will you unwind the safes in the darkness? ...

-Do you really need mobility and you will spin a fallen satellite in a bare field ...

- Is it worth it to pay extra for a design ...

In some ways they were right

The screwdriver must WRAP and TURN, the electric screwdriver must do this with electricity

So the technical task for himself was born "to make a micro-electric screwdriver with minimal costs"

and so it will be required

- bit holder

- source of power

- cheto-type case

- (instead of snot decided to use) hot melt adhesive (it is cheaper)

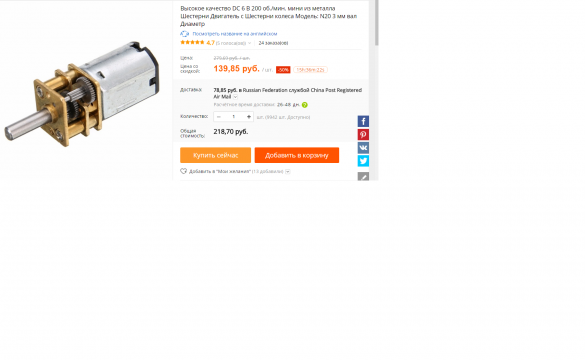

The gear motor is the cheapest of the smallest.

a 6-volt power supply produces 200 rpm (as it turned out later)

The bit holder was taken from a set for 50 rubles from the Fix Price store.

Something like this, and ruthlessly broken out of the handle

Rummaging through PLYUSHKIN’s reserves, a power supply unit was found that lay unnecessarily (AND THIS IS NEEDED) 20 years or 15

It was incredible luck that it has a + to - switch and vice versa, which will give the product a reverse function

The small sadness was that the plug on it was only for super ancient sockets, later it was ruthlessly broken off and replaced with a cord from a burned soldering iron (the same for 50 rubles bought)

After receiving parcels from China with a gear motor in the mail, we proceed to assembly

Holder for bits with glue on the shaft using hot melt adhesive.

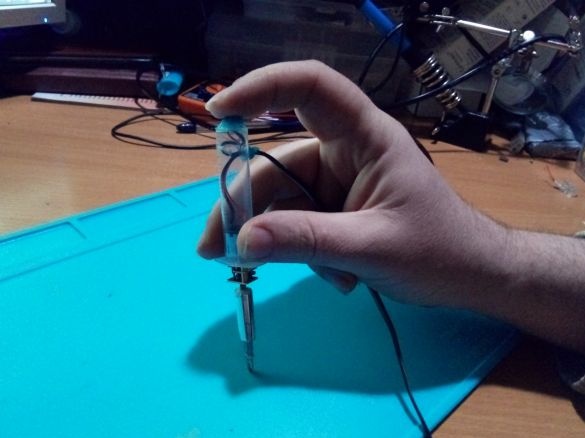

The motor is PERFECT in size with a 5 cc syringe.

On top of the syringe (with hot melt adhesive) we install a mini-button from a burned-out telephone headset.

We connect all components with wires.

We are experiencing.

During the tests it was revealed that 3V power supply is enough for comfortable operation

Quite powerful torque, the stingy screws can be hidden with your hand, hold the screwdriver comfortably, and like a classic with a rotating top

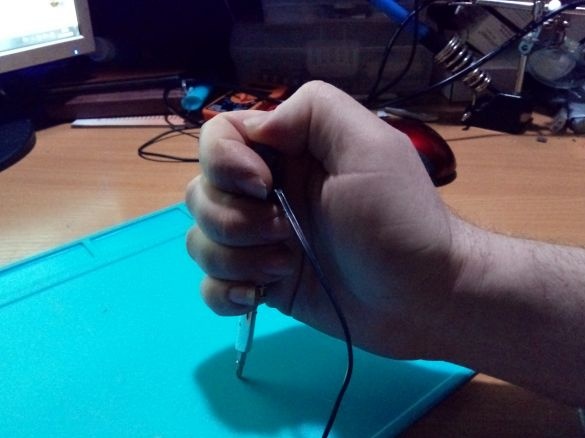

And a side grip

One power button on a screwdriver is enough

Since we first unscrew the 20 screws, then turn on the reverse on the power supply and tighten the 18 screws (2 sperm Plyushkin, for the future).

So with Plyushkin we are establishing a mass production (we have 30 more different power supplies) and ravaging xiaomi.

The first opus, you can throw stones .... (then we will collect them with Plyushkin and impose a toad on a pond.)