Hello to all lovers homemade. For every master involved in electronics, this is familiar when you need to solder wires to batteries such as 18650 wires, they are not advised to do this with normal soldering, since you can overheat the battery, which in extreme cases can damage it, and since the second option is spot welding , it is in this article that I will tell you how to make my home-made spot welding with the smallest investments, the main donor of which will be the microwave.

Before reading this article, I suggest that you familiarize yourself with the video, which shows the entire process of making homemade products and tests under various conditions.

In order to do spot welding do it yourself, you will need:

* Microwave transformer

* Copper single wire, cross section, the thicker the better

* Wire for the welding machine 1 meter

* A pair of crimp lugs with a hole

* Two bolts with nut M10

* Hacksaw

* Drill, metal drill

* Microwave button

* 220V power cord

That's all it takes to build our homemade product.

Step one.

First you need to find a microwave, from which you will need a transformer and a button, a power cord is also useful, which for convenience has two terminals with insulation.

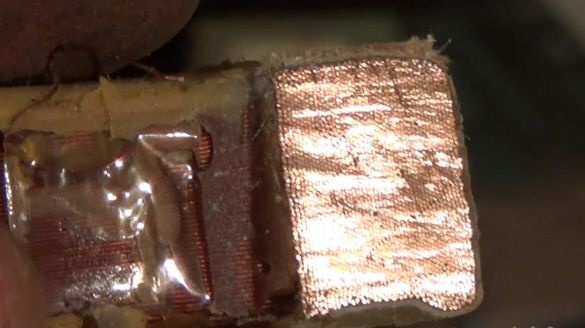

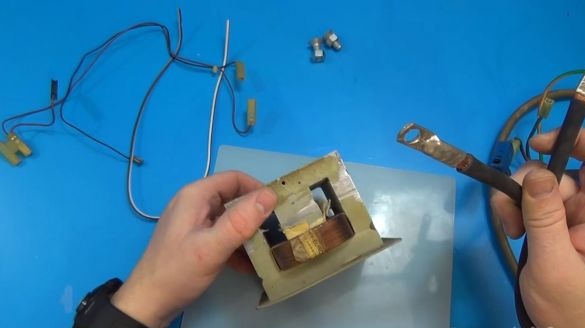

We disassemble the transformer. For this homemade product, it is necessary to leave the primary winding, the secondary one must be removed.

In order not to damage the primary winding, saw off the protruding parts of the secondary on the sides with a hacksaw. We do this carefully and follow, so as not to hurt the turns of another winding.

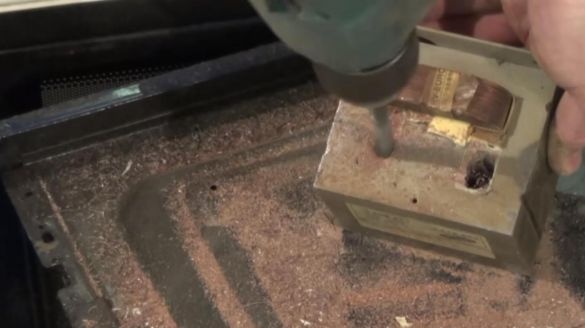

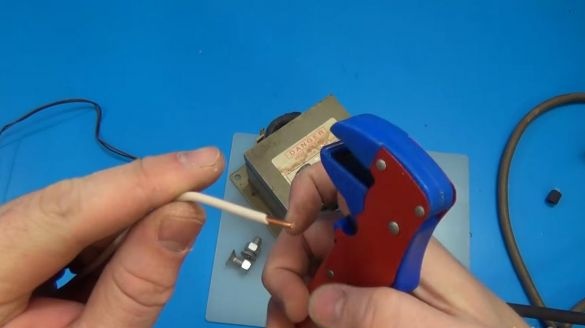

After the excess protruding parts of the winding are sawn off, you need to pull out and the part that is inside the transformer, we drill it with an electric drill and a drill for metal.

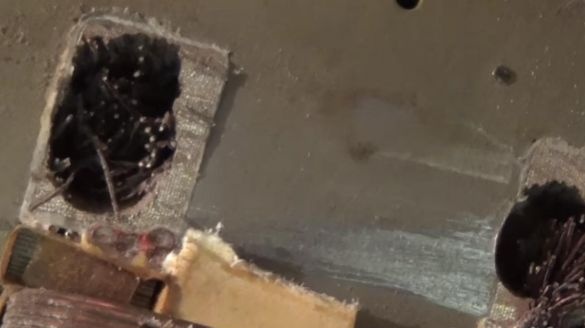

When the winding is drilled, we proceed to its complete removal, through the spacer from the metal we knock out the remaining parts of the windings, at the end they can already be pulled out by hand.

Step Two

After gutting the secondary winding of the transformer, remove the metal shunts that were under the winding.

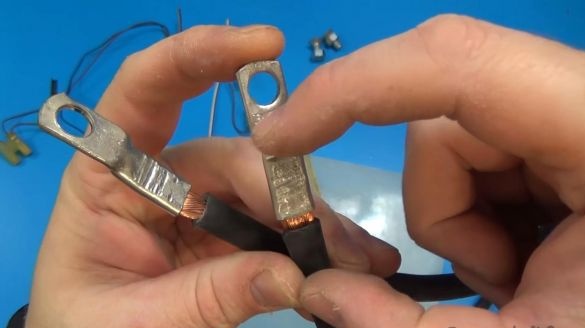

Next, we take a wire for the welding machine, the cross section should be at least 16 square cm, strip the insulation at both ends and crimp the terminals, who have a special device, it is better to do it with it, I made it with a normal hammer.

Step Three

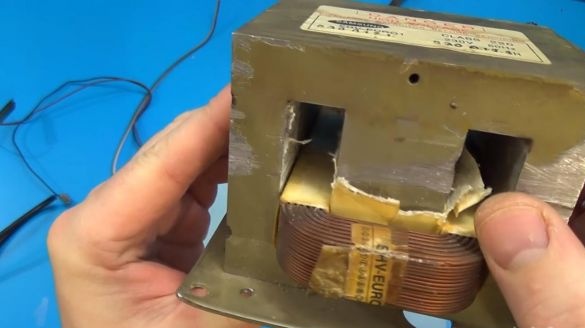

When the terminals are installed on the wire, you can thread it into the transformer, do one or two turns, some wind one and a half, it all depends on how much space there is for this.

One end of the wire comes out from below, the other from above.

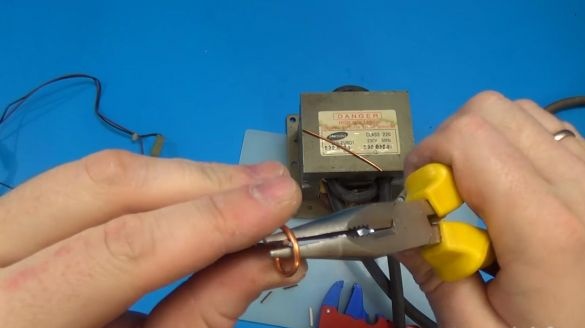

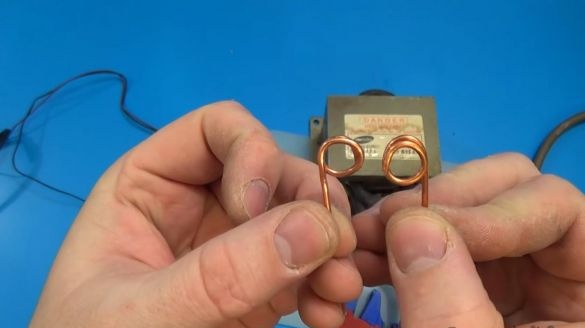

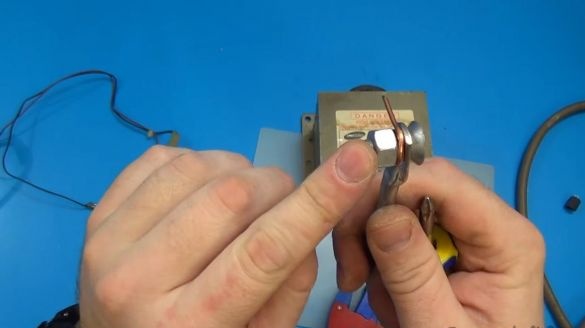

Now we make copper electrodes, strip the single-core wire and twist it into a circle for clamping with a bolt, we do the same with the second electrode.

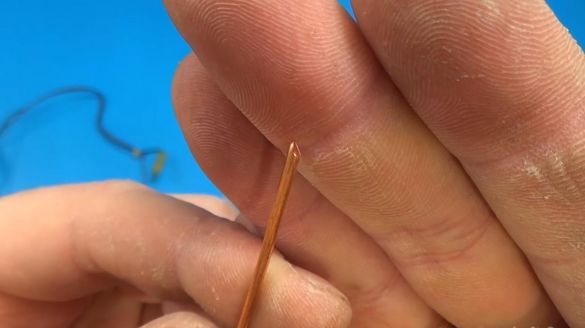

The tips of these electrodes need to be sharpened, this can be done using side cutters, after which we screw them onto the tips using bolts with a nut.

Step Four

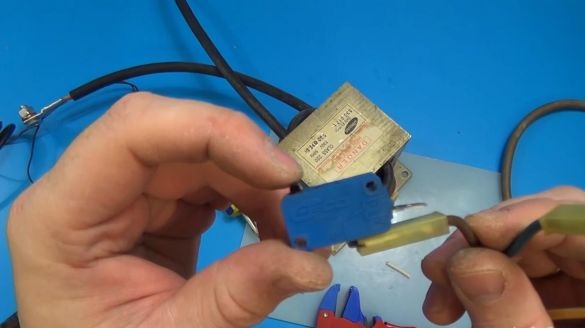

Next, we proceed to the supply wire, connect one of its contacts to the output of the primary winding of the transformer, and connect the wire from the button to the second one, which will interrupt the power supply.

When the button is pressed, the transformer will turn on and weld the nickel plate to the 18650 battery, the output voltage is almost 1.7 volts.

Step Five

At the end, we install a plastic spacer between the output contacts so that there is no short circuit and we fasten everything with electrical tape.

In the future, everything can be finalized and replaced with something more aesthetic and functional. We arrange the electrodes so that there are no skews when touching, and leave a gap between them of about 3-4 mm.

At this point, microwave spot welding is ready and can be tested.

First we try on a regular plate, we also check how the nickel plate holds on the 18650 batteries, points are formed during welding, but when they put in the force, they do not withstand the load, as for assembling some kind of electric homemade products, I think this is enough, if necessary, you can increase the number of turns and the cross section of the wire, as well as replacing the electrodes with more powerful ones, since with such a cross section it turned out that this section is slightly lacking, from which there are power losses.

Thank you all for your attention and creative success.