And this article will describe the detailed assembly process.

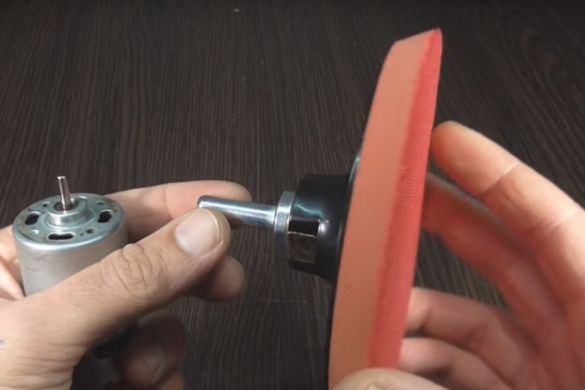

For the manufacture, the author took a 12 volt electric motor.

Velcro disc.

Since the shaft of the engine is small in diameter and can not withstand such a load, the author decided to put a pair of bearings on the disk shaft, and the engine will transmit rotation to the disk through the belt. It turns out this kind of not a big gearbox.

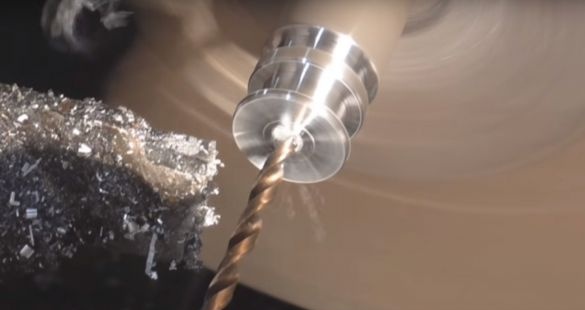

To implement such an idea, he will need to grind two pulleys of different sizes. The author will make a pulley for a disk from a metal round log, and it will be larger. And the author will draw a pulley for the engine from a bar of magnesium. According to the author, this is durable and at the same time lightweight material.

After both pulleys were machined. The pulley intended for the engine the author pressed onto the shaft with a vise.

And he began to manufacture bearings for bearings. Its author will make a 3/4 inch piece of metal pipe. Boring it from the inside to the size of the bearings and making grooves around the circlips around the edges.

The author also prepared a sleeve for mounting the engine to the bed.

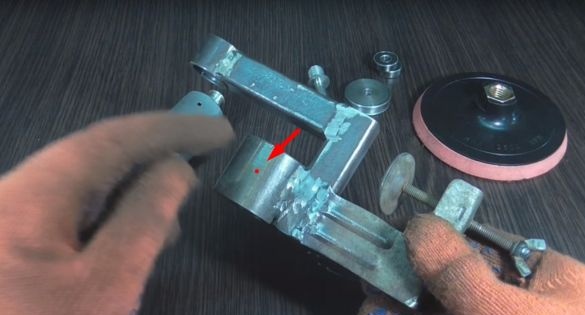

The author will make the bed for the machine from a pair of pieces of a profile pipe, which he will weld as shown in the photo.

Then it will weld a pre-prepared sleeve to them with the help of which it will fasten the engine, and it will also weld a cage for bearings.

And for fixing the machine, the author will weld an old clamp to it.

On the sleeve for the engine, the author will make a small hole, and will thread in it later on, he will screw a bolt into this hole and thus fix the engine.

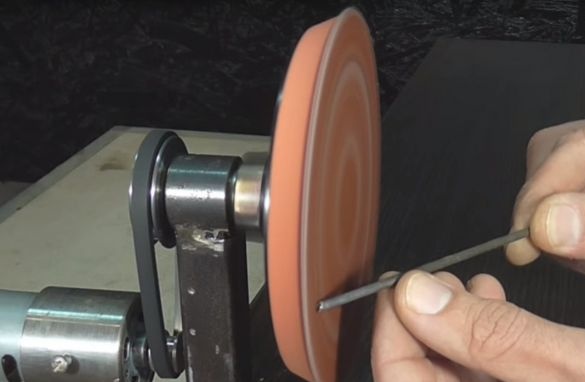

Then the author installed the bearings by putting a pair of washers between them and put the snap rings.

Then he put the drive shaft in the bearings, put on a couple of washers again and installed a pulley.

To prevent the pulley from turning, it will fix it by welding.

As a belt, he will use a sealing gum, from such an oil filter. 51

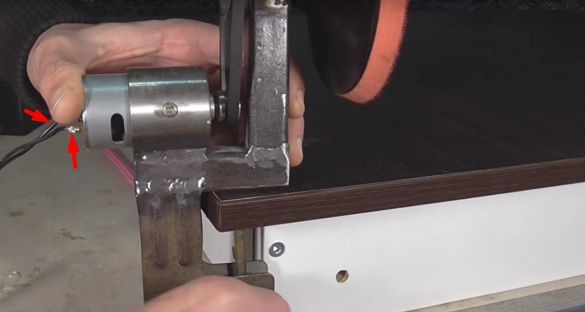

After the belt was dressed, the author set the alignment of the pulleys and fixed the engine with a bolt.

Then he screwed the disc.

Here is a view of the machine in the assembled state and is ready for the test.

Of course, the author soldered to the engine two wires from a 12 volt power supply.

Having attached the machine to the table and glued sandpaper, the author proceeded to the test. The photo shows that the machine copes with its tasks. Of course, on such a machine you will not process anything large. But as the author says, such a machine can greatly help in any small jewelry work.

Thank you all very much and see you soon.

Homemade machine video: