220 volts from firewood. Thermo-electric generator.

The main problem of using thermoelectric modules is a thin boundary temperature transition, which is difficult to observe.

With proper installation, you will not be able to achieve destruction, given the constant heat sink by the radiator.

Unless of course coal is heated, which is strictly prohibited due to the high combustion temperature and the danger of metal melting.

Moreover, this is not a novelty, finished stoves have been sold for more than 10 years.

It is desirable to connect directly to the load through the stabilization unit.

To batteries it is possible directly, but only through a diode. Otherwise, in a cold oven, you will heat or remove heat back, depending on the polarity of the connection.

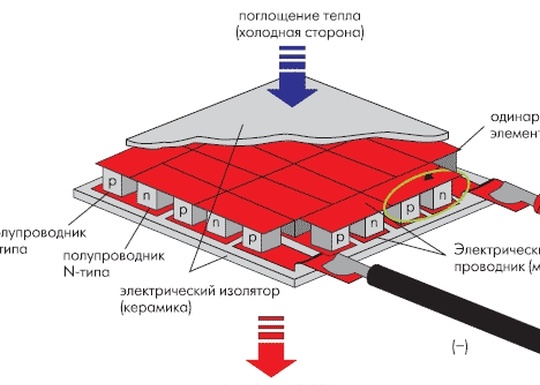

Structurally, the product consists of five elements.

The first, thermo-compensation-stabilizing, on the hinges, serves to compensate for temperature deformations, .. (bends, changes in geometry) during rapid or uneven heating.

That is, being an independent part, without a rigid connection with the second element, it can change its geometry, but at the same time the second element does not bend, to which the generating modules are pressed.

At the same time, it transfers heat to a neighboring element by contact, infrared and convection.

In which the constant contact of the coolant with the generating module and further with the radiator is ensured, protecting the latter from mechanical destruction and maintaining good thermal contact.

In other words, if the design of the heated element were monolithic, the hot part would very significantly change its shape relative to the cooled radiator, the interlayer between which is the third element, the generating modules themselves.

Simply, the modules would collapse or not reach the specified mode.

The fourth and fifth structural elements are the radiator and fans, respectively.

In case of failure of the fan or two, the active furnace should be stopped, closing the air flow. And wait until the stove cools down.