Hello to all lovers homemade. Often you have to look for some containers for your homemade products, be it paint or some kind of solvent. But the fact is that such containers are not always found, and also it is not possible to find the required volume. Having asked this question, I decided that it was necessary to think up how easy and simple, without special efforts, to make a tank of a suitable size and volume, without spending any financial resources. In this article I will tell you how to make any container out of a bottle using a homemade glass bottle cutter, which will be discussed later.

Before you start reading the article, I suggest that you familiarize yourself with the video, which shows the assembly process, and also demonstrates the operation of the finished device, if you can call it that.

In order to make this homemade glass bottle cutter, you will need:

* Boards, small sheets of chipboard or parquet are also suitable

* Wood screws

* Screwdriver

* Wood drill

* Nichrome thread

* Glass bottle

* Power supply with a voltage of 12V

* Powerful copper wires

That's all it takes to make a device with which it will be possible to cut bottles of glass, budget and does not take a lot of time to make.

Step one.

First you need to make a frame, since in each device it is an indispensable thing, in this case it is made of sheets of chipboard, which must be fastened to each other at right angles.

Here you can use not only a sheet of chipboard, sawn into two parts, but also parquet or a board made of hard wood.

Next, you need to screw this "jamb" to another plank, but before that, drill holes for the screws, since the board can crack, the wider the base, the more stable the whole structure will be.

Step Two

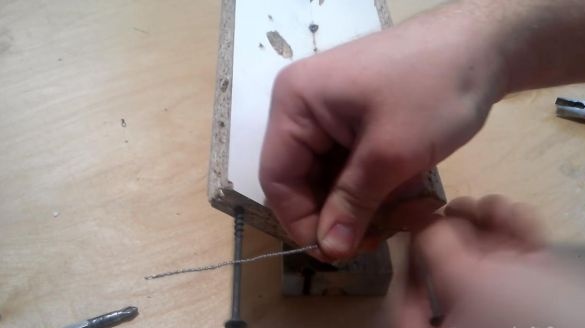

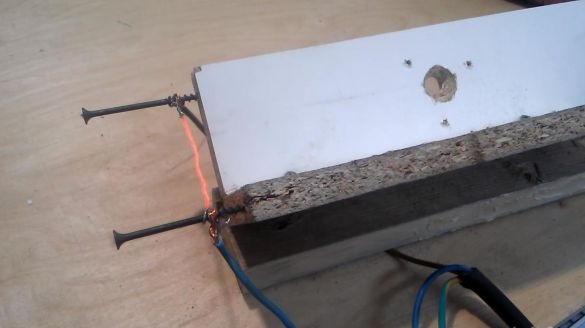

After making the frame, you need to make the cutting part, here it plays the role of a nichrome thread, which can be purchased, for example, in a radio store. This nichrome thread needs to be twisted into a spiral, four layers will be enough.Then you need to screw two screws to the end of the frame, you need to screw a nichrome thread on them and tightly fix using pliers, we also attach powerful copper wires to them.

Step Three

Since the nichrome thread should heat up sufficiently enough, as a result of which the glass will be cut, you will need a powerful power supply with a voltage of at least 12 V, in this case the power supply from the music center with an output voltage of 21 V has turned up, which is quite enough for cutting bottles nichrome.

We connect the wires from the nichrome thread to the power supply and test the homemade. To install the bottle in one position so that it does not mix relative to the thread, install a screw that abuts the neck, thereby preventing horizontal movement of the bottle.

That's all, the bottle is cut quite simply, turn on the power supply and slowly rotate the bottle, touching the nichrome thread, as a result, it heats up at the touch point and after some time the glass is cut off, which ultimately makes it possible to get completely useful bottles capacities of the capacity and sizes you need.

Thank you all for your attention and creative success.