This article will cover how to make an extruder. But first, let’s know what an extruder and extrusion are.

An extruder is a machine for continuously processing polymer raw materials into a homogeneous melt and shaping it by forcing it through an extrusion head and a special calibrating device.

Extrusion (technological process) is a method and process for producing products from polymeric materials by forcing a melt of material through a forming hole in an extruder.

In simple terms, in the chamber of the device, the plastic is melted and squeezed out under pressure through the nozzle of the head into the mold.

Tools and materials:

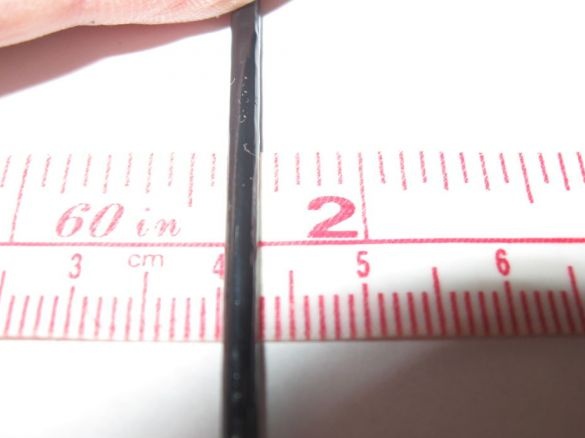

-Metal pipe with thread on the end;

-Face head;

Extender for the head;

-Welding machine;

-USHM;

-Vise;

-File;

-Perforated corner;

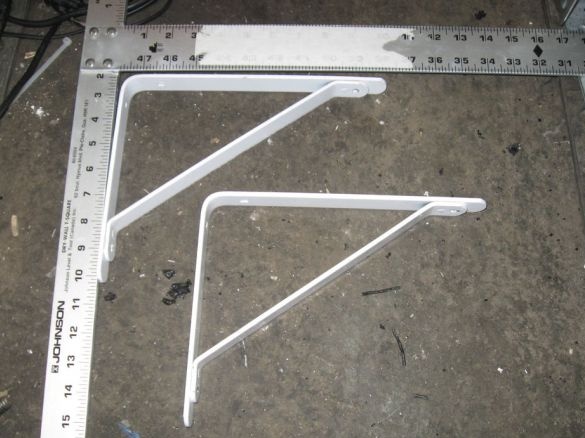

-Two brackets;

-Copper tube;

-Fasteners;

-Metal clamp;

-Heating element;

- Thermostat with a sensor;

-Fiberglass;

- Aluminum tape;

-Fitting;

-Metal strip;

-Gon;

-Drill;

Step One: Piston

The extruder chamber will be from a 20 mm metal pipe. The inner wall of the pipe should be flat without a seam. Inside the chamber, plastic will be laid, heated and squeezed out through the nozzle. You need a piston to extrude. The master made the piston from the socket head. I picked up the head by the diameter of the tube. Installed it on an extension cord. Welded the head to the extension cord. Brew the end hole of the head.

Step Two: Camera

There is a thread at one end of the pipe. At the opposite end makes a boot window. Marks and cuts the pipe wall. Cleans the edges with a file. Through the slot, plastic will be loaded into the chamber.

Screws the adapter sleeve onto the thread.

Step Three: Heating Element

Now you need to install a heating element on the camera. The master uses two heating elements of 400 watts each. From a perforated corner makes a mount. Secures heaters with metal clamps. A copper tube is installed between the corners.A temperature sensor is installed in the handset.

Step Four: Thermal Insulation

Fiberglass wraps the device. Metal tape wraps on top of fiberglass. Thermal insulation will prevent heat loss and protect against accidental contact.

Step Five: Installation

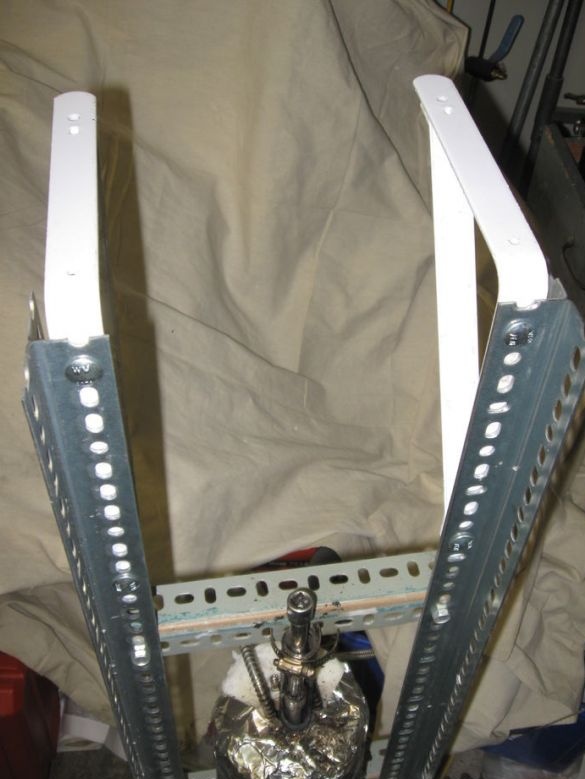

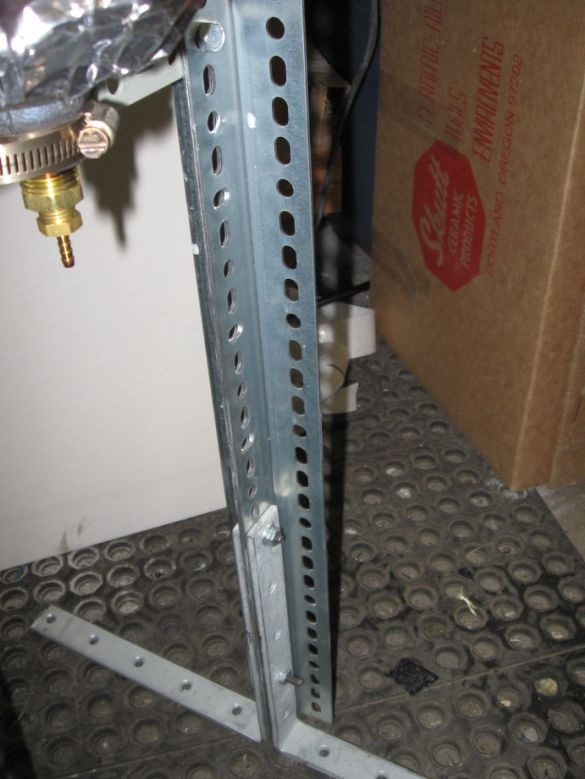

From the corner, the master made a frame for attaching the extruder. Secured the device to the frame.

Step Six: Nozzle

The role of the nozzle in the extruder is played by a brass adapter. Screws the adapter.

Seventh step: lever

Now you need to make a lever. First, the master lengthens the piston pusher.

Fastens the corners to the frame. Fastens the transverse pipe to the corners. A pipe with a slot connects to the cross member. He takes another piece of pipe. One end is flattened (it is mounted in the slots of the previous element), the other end is connected to the piston rod. All connections are movable.

Step Eight: Testing the Machine

First you need to warm the chamber above the melting temperature of the plastic by 2-3 degrees. Then load the crushed plastic into the chamber. A little smoke in the beginning is normal, if there is a lot of smoke and it goes on constantly, you need to lower the temperature.

It is necessary to work with the extruder in a well-ventilated area using protective equipment.