The reason for this article was the appearance of two batteries for the Bosch NiMH 14.4V, 2.6Ah screwdriver. These batteries were replaced with new ones due to their refusal to work after two or three years of inactivity. Storage of batteries took place in a case, in room conditions, with a full charge on the "native" memory, after rare use. At the next removal from the case for urgent work, the battery of the screwdriver gave all its strength in 5-7 minutes. After the same charge time, the charger reported that the charge was full. And so in a circle, for the entire time of work. The second backup battery behaved similarly. After a natural replacement, they came to me.

A nickel-metal hydride cordless screwdriver battery with an operating voltage of 14.4 volts is assembled from 12 separate elements with a typical voltage of 1.2 volts connected in series. But different elements in the production receive a certain range of characteristics. Some have more capacity, while others have less. As a result of constant charging in a bundle, elements with a lower capacity are constantly recharged. Because of this, they are rapidly degrading. Batteries with a smaller capacity will also degrade during discharge. They are discharged earlier than other elements, and further discharge leads to their deep discharge. Because of this, in the event of a NiMH battery malfunction for the screwdriver, one or more battery cells will usually fail, and others will follow. Therefore, the main task when repairing the battery of a screwdriver is to identify failed elements. And in the future, it is possible to restore the battery of a screwdriver with a simple set of serviceable elements from the main and spare batteries or with an attempt to restore some elements to complete the battery.

Opinions are often expressed on the Internet, often controversial, on how to restore such batteries. Many consider this simply unpromising or ineffective due to the short life after restoration. But since the above batteries had a small number of charge-discharge cycles, they actually operated under load only for a short time, I decided to try out the possibility of their element-by-element analysis and, if possible, recovery. You may be able to collect a spare battery for a screwdriver or use the "surviving" elements in others homemaderequiring the discharge of high discharge current in a short time.

To identify unreliable battery cells:

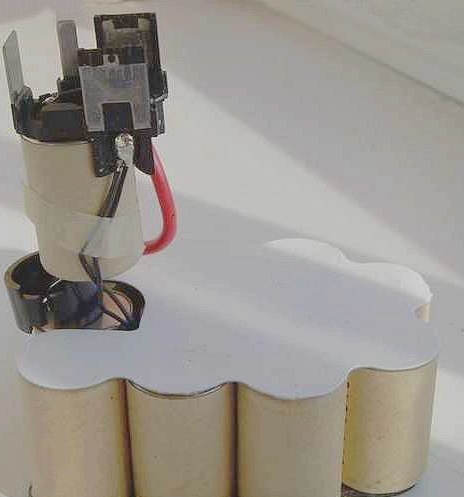

1. Dismantled the battery case of a screwdriver (4 screws) and removed from it a block of series-connected cans (12 pieces) of NiMH battery cells.

2. Having removed the upper and lower insulating gaskets, he released the plates connecting the poles of the elements for contact.

3. Inspection of the battery cells did not reveal any external defects (dents, swelling, smudges, corrosion) that could affect the operation of the battery.

4. For the proper operation of NiMH batteries, it is recommended to maintain the operating voltage on the cells within 1.2–1.4 volts, a reduction to 0.9 -1.0 volts is allowed. He measured the voltage on each element of the battery with a multimeter. The voltage spread across all the battery elements was within 1.01 ... 1.24 volts (i.e., within the normal range for a discharged battery), but the battery in the screwdriver practically does not work.

5. Repeated paragraphs 1 - 4 on the second battery for the screwdriver. The result is similar.

6. To identify the problem, I conducted comparative measurements of the current given by each element on the internal resistance of the multimeter shunt. Short-term measurements showed that 4 elements out of 24 can give a current of more than 1 ampere, and the rest - less than 0.2 amperes. In other words, only 4 elements of all had some capacity and for a short time supported the work of a screwdriver.

7. For work on trying to restore low-capacity elements and charging the working ones, I took apart the NiMH battery blocks. To do this, I cut the jumpers connecting the elements with ordinary scissors. If possible in the future, connecting the elements by soldering jumper residues will not be a problem.

8. Four selected elements with a certain capacity are marked and ready for experimentation.

9. To restore or reject individual elements, it is necessary to charge the element with a current of 0.5 ... 1.0C (fast charge) to the nominal capacity, limiting the charge according to the estimated time. But to calculate the time, you need to know the capacity and initial charge of the battery cell. Therefore, to exclude the unknown initial charge in the calculations, it is necessary to first discharge the restored battery.

Checking the capacity of a charged element can also be checked by its discharge, controlling the current and discharge time.

In connection with the above, the first step to determine the characteristics of the battery will be to discharge the cell at a constant load, with a control over the minimum residual voltage of 0.9 ... 1.0 volts, to exclude deep discharge. Everything is simple with the current - the smaller the discharge current, the more complete the discharge and the more efficient the process, but the charge time will increase. Nickel-metal hydride batteries can give a lot of current, but it is not recommended to set values higher than 0.5C during discharge. This leads to a reduction in the number of charge-discharge cycles and a decrease in service life. As a result, we take a discharge current of 100 mA.

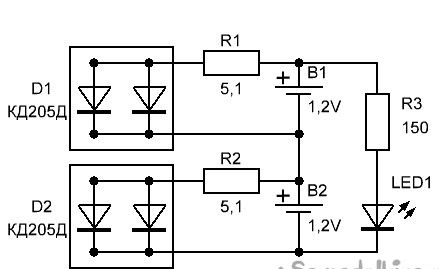

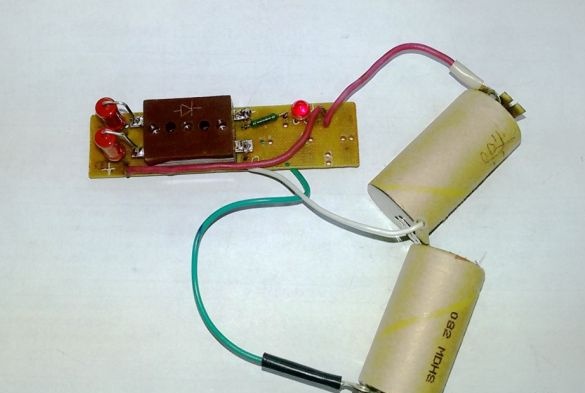

10. To discharge the battery cells, we assemble a simple circuit that allows you to control the discharge process by the glow of the LED.

To ensure ignition of the LED, we install two elements connected in series at the same time. Each of them is discharged into its own chain of resistance (which determines the discharge current) and diodes (which determine the minimum voltage on the battery cell within 0.9 ... 1.0 volts). This minimum voltage on the element is obtained automatically. The end of the discharge cycle when the LED is turned off.

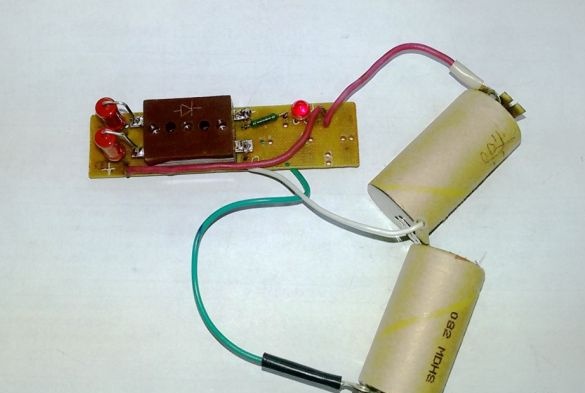

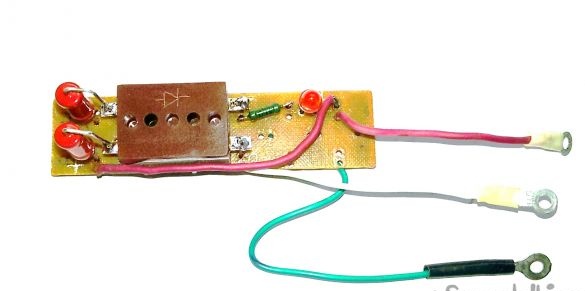

11. We select the parts according to the scheme and assemble it on a piece of PCB cut from a universal circuit board.

12. We connect two elements in series, in accordance with the polarity, do not forget to connect the midpoint (white wire) and observe the glow of the LED. By the duration of the discharge it is possible to navigate about the capacity of the battery cell.

13. The capacity of the cell can be measured by discharging a fully charged battery. To do this, you need to detect the discharge time and multiply it by the discharge current. This will be the capacity that needs to be compared with the nominal. Some devices, such as the iMAX-B6, take measurements automatically. We will act in a more economical way. Since to assess the possibility of using the battery elements, we need only approximate values of the capacitance, we will conduct periodic measurements on two elements with extreme characteristics.

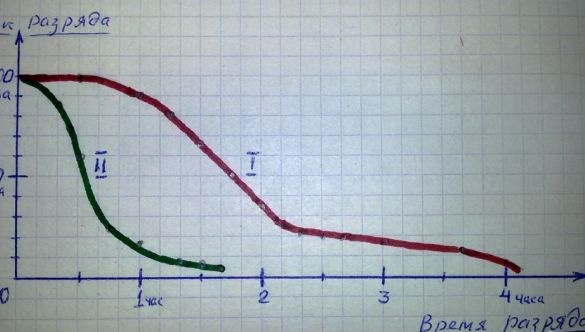

14. When periodically measuring the current in the control process of a discharge on a given device, a previously discharged and fully charged battery cell (paragraphs 9 ... 12), it is possible to see the difference between the cells, which is reflected in the graph

Graph 1 (red line) reflects the discharge process of elements selected by measurements (item 8), which initially have some capacity. In accordance with measurements and calculations, the capacity of this battery cell is about 95 hours, which is 44% of the nominal capacity. Due to the instability of the discharge current, the calculation was performed by summing the component capacitances over short periods of discharge time (10-15 min) following one after another. The discharge current was taken as the average, between the beginning and end of each of the periods.

Graph 2 (green line) shows the process of discharging an element with a minimum initial capacity. Measurements and calculations are performed similarly. The capacity of this element is about 50 hours (23%). The nature of the drop in the discharge current differs sharply from the previous one and indicates a small capacity of the element.

The graphs show that the potential capacity of the battery cell, for the purpose of rejection, can be determined during the first 20-30 minutes of the control discharge by the magnitude of the discharge current drop. And also, despite one full cycle of discharge and the estimated charge of an old battery cell, without additional recovery measures, its capacity is practically not restored.

The reason for a significant drop in the capacity of nickel metal hydride elements may be the memory effect. It manifests itself in cycles of incomplete discharge and subsequent charge. As a result of such operation, the battery “remembers” the ever lower lower boundary of the discharge, which decreases the capacity. Part of the active mass of the battery falls out of the process.

To eliminate this effect, it is recommended to regularly restore or train the batteries. To do this, according to the above diagram, the discharge is carried out and then the complete charging process. It is recommended to do several such cycles.

Another way to restore NiMH batteries is to pass current through them in short pulses. The current should be ten times higher than the value of the capacitance of the element. At the same time, dendrites are destroyed and the battery is “updated”. Further, his training is carried out in the form of several charge-discharge cycles.