Despite its formidable appearance, this gun is just a quality toy. Such a rubber arrow has two barrels and can fire 24 gum at a time, or 12 individually.

Tools and materials:

-Board;

Reciprocating saw;

-Pencil;

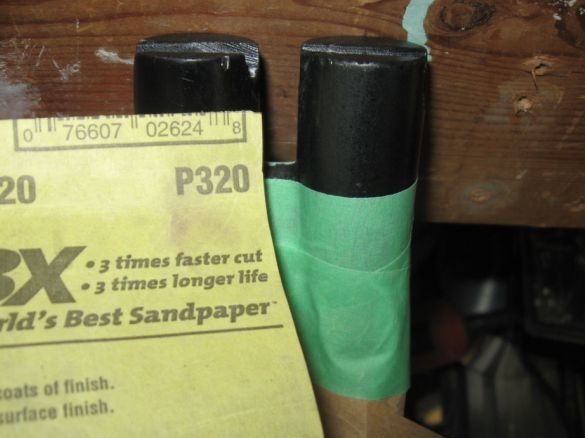

-Tape grinding machine;

-Sandpaper;

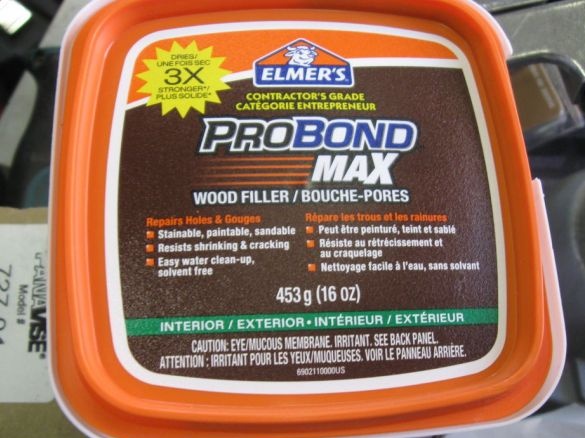

- Putty;

-Putty knife;

- Stain;

-Varnish;

-Gon;

-Rail;

- Joiner's glue;

- Clamps;

-Wood dowel;

- Rubber bands;

-Aluminum rod;

-Hacksaw;

-File;

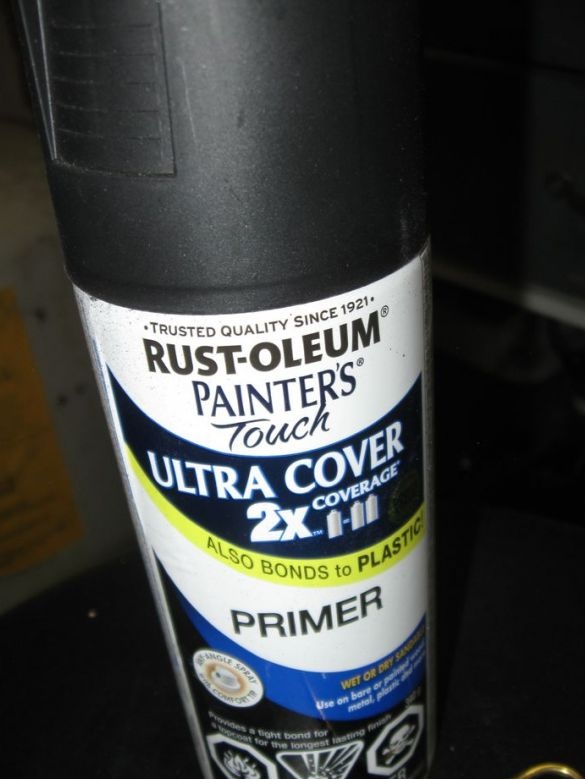

-Paint;

-EVA (foamed rubber);

-Knife;

-Scissors;

-Burner;

-Drill;

-Fasteners;

- Brass plates;

- Brass wire;

-Copper tube;

-Solder;

Step One: Butt

First, the master makes a butt for a rubber arrow.

On the board draws the outline of the butt. Trims excess wood.

On a belt grinding machine it processes the butt, gives the desired shape.

It brings the butt manually.

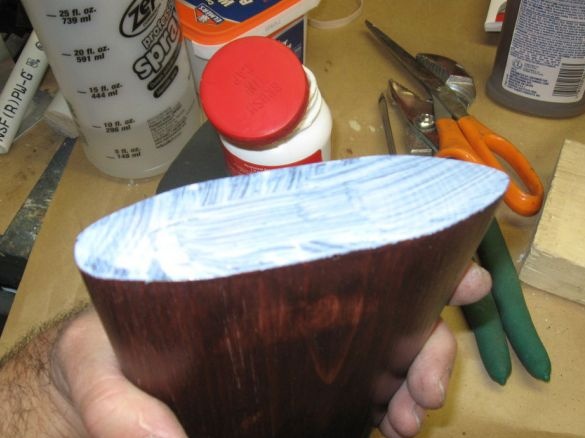

Putty chips. Apply a layer of stain to the butt. Then a protective coating.

Step Two: forend

The forend is made of slats. Cuts slats of the desired length. Glues a box out of them. Processes on a grinding machine. Then it is applied to the forend.

Step Three: Trunks

The trunks are made of thick wooden dowels. Glues the dowel, laying between them a small block in front and behind. An aluminum core serves as a support for gluing.

After gluing, it fills the gap between the trunks with putty.

Step Four: barrel support

The trunk is made similar to the forearm, given the size. Glues three strips. Then glues the end cap. After gluing, processes the support on the machine, grinds. Glues the trunks to the support.

Step Five: Trunk Trimming

At the ends of the trunks makes slots, the edge of the gum will cling to them. Then he paints everything with black paint.

Step six: butt pad

The butt plate on the butt is called the butt plate. As a rule, the back plate is made of soft, non-slip material, leather, rubber, etc. and serves for depreciation during recoil and convenience when aiming. Of course, there is no recoil in this gun, but the author wanted to make it as close as possible to the present. The recoil pad master made of foam rubber.I cut two parts of the butt plate in the shape of the butt part of the butt. Glued two parts. Knife gave the desired shape. I glued the butt plate to the butt.

Seventh step: assembly

Fastens the barrel to the butt with a screw. Sets the forearm.

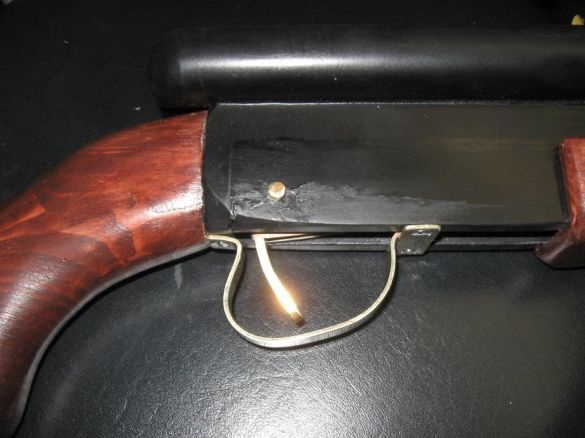

Step Eight: Trigger

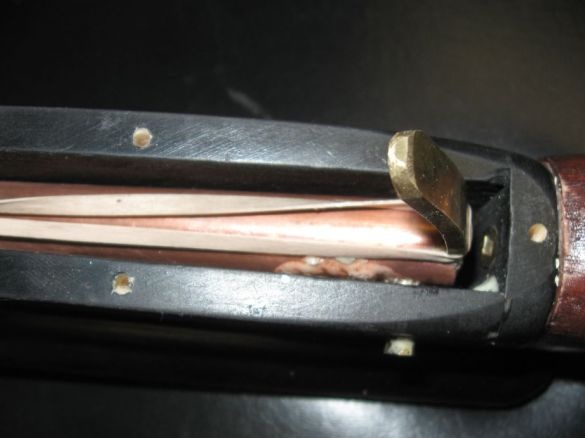

The trigger mechanism is a system of levers. Between the trunks, two hooks are fixed, for which, at one end, an elastic band clings (the second end to the trunks). Bottom hooks abut against a copper pipe with a trigger at the end. Pulling the trigger releases the hooks and the rubber bands break. Moreover, the hooks have different lengths and due to this, by slightly pulling the trigger, you can release the rubber bands on one hook, or pulling to the end to shoot with all the rubber bands.

Between the trunks makes a cut.

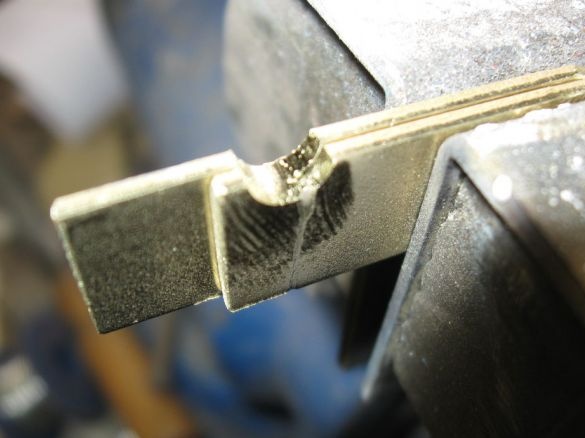

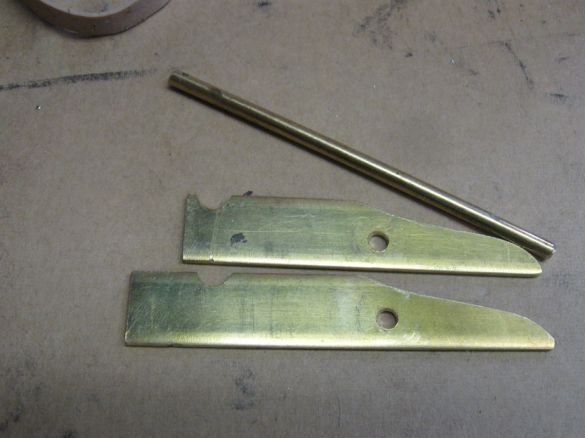

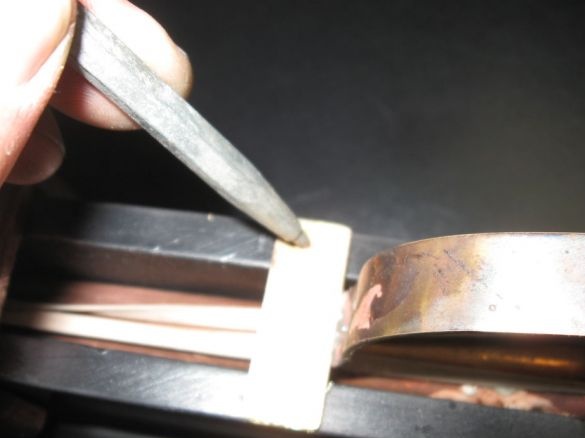

Two hooks are cut from brass.

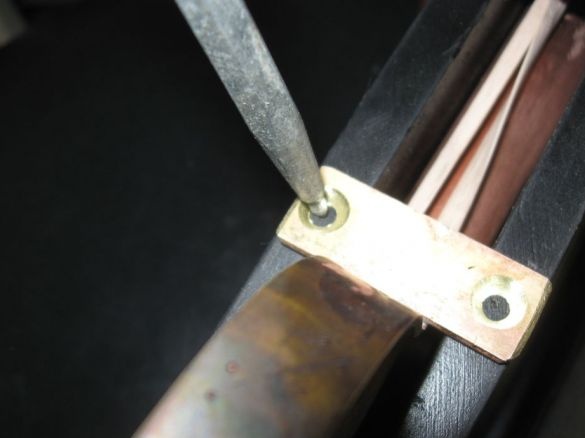

Drills holes for the axis.

Sharpen the hooks.

Washers are installed between the hooks. The axis is made of brass wire.

Slices a copper pipe. On the one hand, the trigger is soldered. The second end seals. Drills a hole for the axis.

Step Nine: Installing the Mechanism

Sets hooks. Then sets the tube with the trigger. Drills a hole in the barrel support. Pokes a hole in the hole. He puts two rubber bands on the stock. Puts the stem into the second hole. Pulls the gum on the trigger.

Step Ten: Trigger

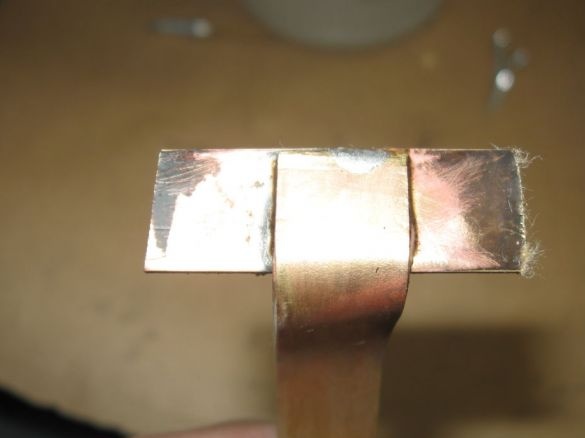

From brass makes a trigger guard.

Heats and bends from the brass strip the desired shape of the bracket.

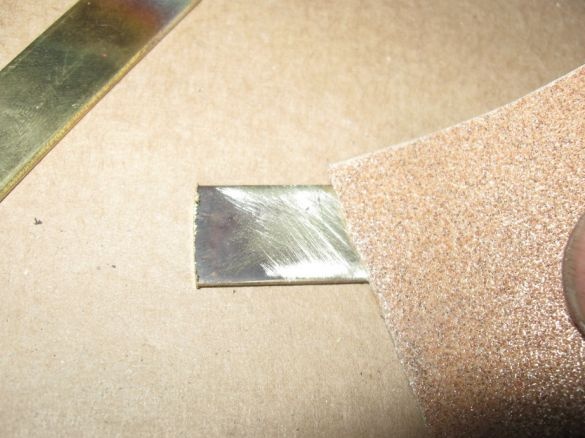

It cleans the end of the bracket and solders the transverse strip to it.

Drill a hole.

Drills a hole for attaching a bracket.

Cleans and polishes the trigger guard.

Screws into place.

Step Eleven: Final

Colors the end of the trunks in orange.

The gun is ready.