A small article on how to make a thermoplastic nut. Such a nut has practically no play, glides well and wears out a little.

Tools and materials:

-Vise;

- hairpin;

- Hacksaw for metal;

-Burner;

-Clamp;

- Toothbrush;

- Lathe (optional);

-Gloves;

Step One: Stud Preparation

At the end of the stud, for which the nut is made or with the same thread, makes cuts.

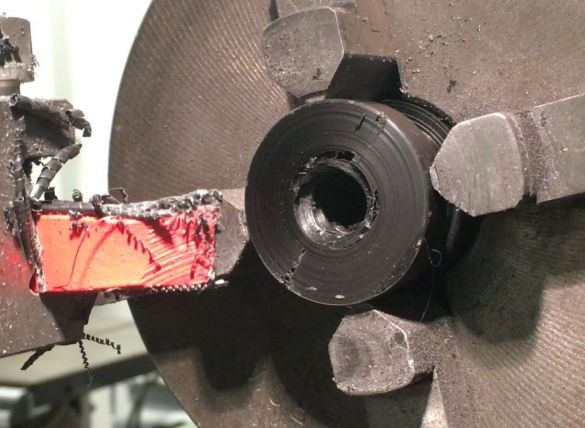

Step Two: Making a Nut

Slices a piece of the rod of the desired length. Drills a hole in the center. Cuts workpieces into two halves. Heats the rod with a burner. Connects on the rod two halves of the workpiece. Heats the workpiece with a burner constantly adding chips.

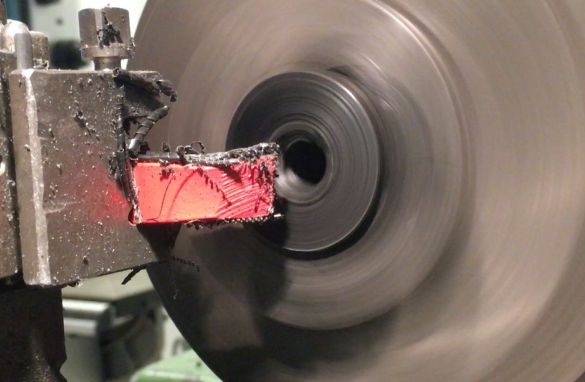

Step Three: Carving

Lubricates the threads with oil. Moves the nut up and down the cut part of the stud. Cleans the chips from the threads with a brush.

Step Four: Nut Processing

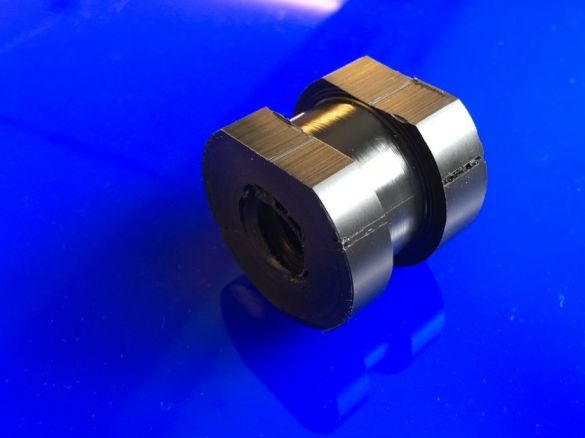

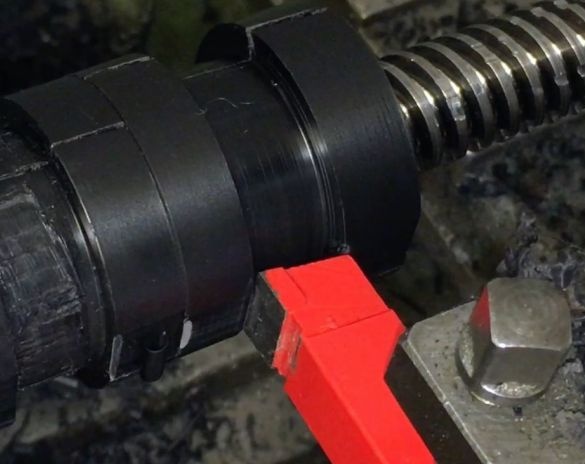

The nut is ready and the next step is performed if necessary and with a lathe. Tightens the nut in the cartridge. Treats the surface of the nut. Grooves a groove. Forms a plane.

The nut is ready.

An example of using a nut.

The whole process of making a nut can be seen in the video.