Greetings to the masters and other onlookers!

A 775 24V motor is used as a power element. These engines are in great demand in the manufacture of various home machine tools and other devices. The rotor of the engine rotates on bearings, and not on the bushings, as in conventional low-cost engines. There is also a built-in propeller that will prevent the engine from overheating during prolonged operation.

As for the other components of the machine, you will need to buy them, here metal gears are used, as well as bearings and a hub. However, such parts can be found in old mechanical watches or simply ordered from China, there is such good in bulk. So, let's take a closer look at how to make a jigsaw!

Materials and tools used by the author:

Material List:

- ;

- board;

- two small bearings, axle, hub, gears, etc .;

- ;

- a saw for a jigsaw;

- screws for wood;

- ;

- power supply 24V.

Tool List:

- soldering iron;

- drill;

- saw for metal;

- screwdriver;

- saw on wood;

- glue gun;

- a drill.

The process of making a jigsaw:

Step one. We assemble the frame and mount the engine

To assemble the frame you will need a piece of board. It needs to be cut into details, as seen in the photo. Next, we connect all these elements using self-tapping screws. Now you can install the engine. To install it, use a purchased plastic mount specifically for this model motor. We fasten the bracket to the base with self-tapping screws, and then fasten the motor itself with screws.

Step Two Install the shaft

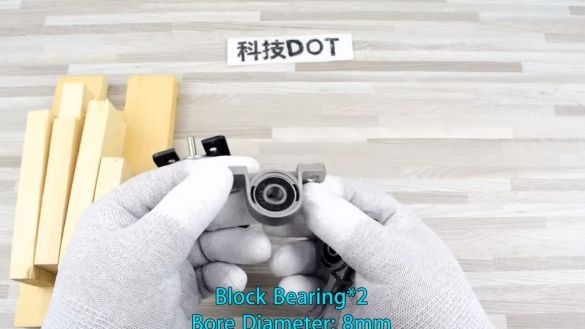

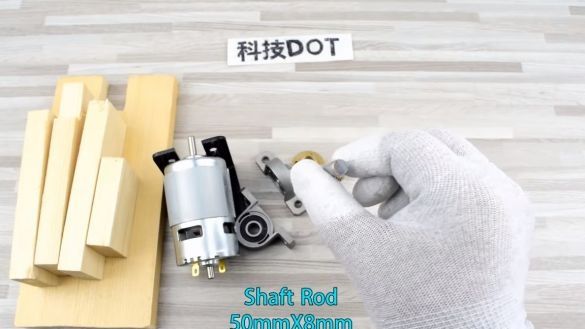

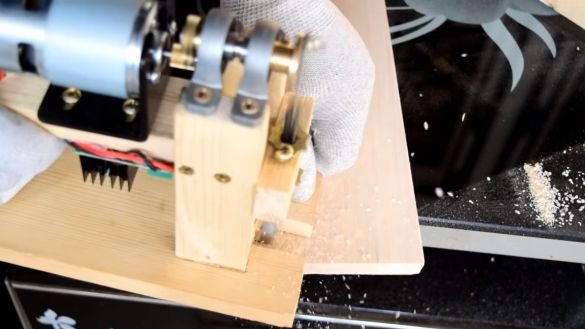

Now you can install the shaft to which the cutting blade will be connected. The shaft has two small bearings with brackets, thanks to which it can be conveniently fixed using self-tapping screws. Power is important for a jigsaw, to get it, you need a gearbox. A small gear is installed on the motor shaft, and a larger one on the working shaft, as a result, we obtain the required torque.

Step Three Production and installation of crank assembly

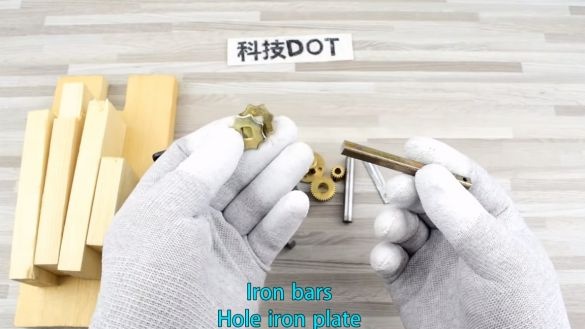

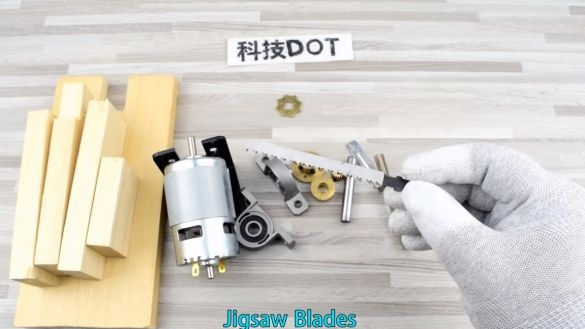

The whole structure works on the basis of a crank assembly, which turns the rotational movements of the engine into reciprocating movements of the knife. First of all, we will make a “pusher”, this is the part on which the cutting blade will be installed. To manufacture this part, we need a steel rod, we take a hacksaw and cut a slot in it for installing the blade in it. You will also need to drill two holes for fastening the blade with bolts and nuts. We also drill two holes in the canvas.

Now we connect the connecting rod to the pusher, thereby connecting it to the hub of the drive shaft. Here you will need a plate with two holes and bolts with nuts. The pusher must have a guide, otherwise the knife during operation can change the angle around its axis. The pusher itself has a rectangular shape, and as the guides we use washers with a square hole or something similar, the author fastens them with screws. At the end, we collect all the nodes as in the photo. Remember to lubricate the gears and bearings, so they will last longer.

The final step was the processing of the frame with a drill with a grinding nozzle to remove nicks and so on, but this is advisable to do before installing all the nodes.

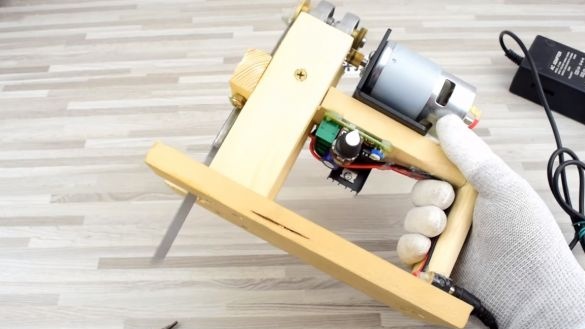

Step Four Connect all nodes

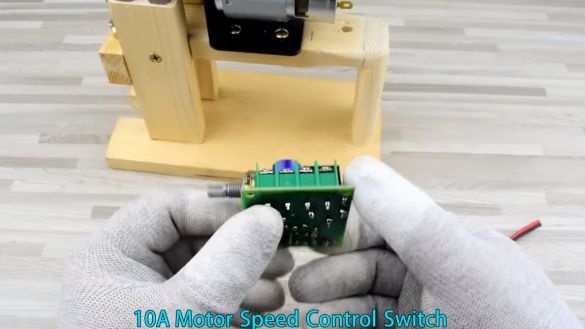

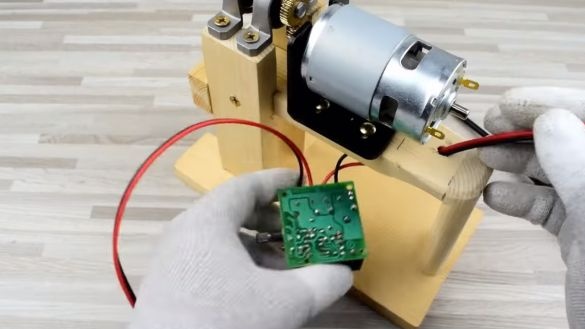

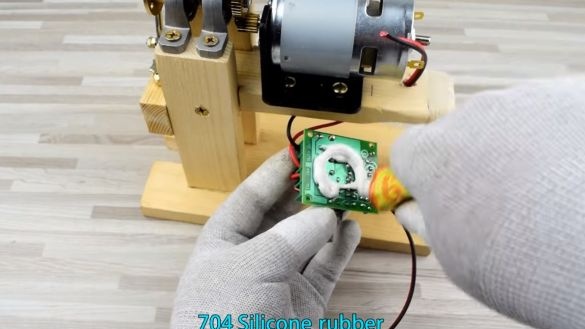

Now you can connect all the nodes, and we will start with the speed controller. Solder all the necessary wires, and glue the board itself to the frame using silicone glue or something similar, and hot glue will do.

We solder wires to the motor, and we also need to install a connector for connecting the power supply. We fix it in a convenient place with hot glue.

Step Five Testing!

That's all, our homemade jigsaw is ready! We install a cutting blade on it and test it! The author homemade perfectly cuts boards, which indicates quite a good performance. Such a jigsaw can easily cut fiberboard or other material. The main advantage here will be mobility, because if you want, a jigsaw can be powered by batteries!

That's all, I hope you enjoyed the project. Good luck and inspiration in making homemade products, share your results with us!