Hi, the inhabitants of our site!

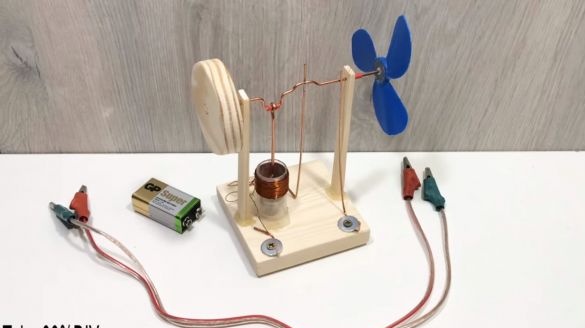

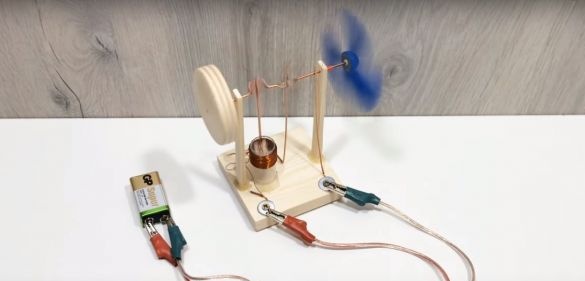

I want to show you how to make a real single-cylinder nine-volt solenoid type electric motor do it yourself from improvised materials to home conditions.

This will require the following materials and tools:

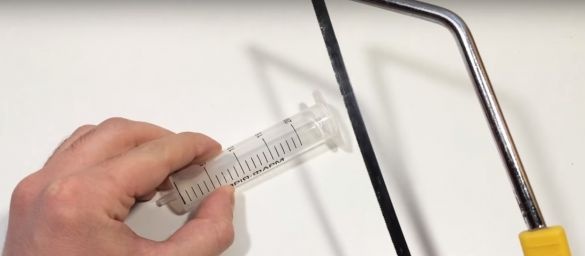

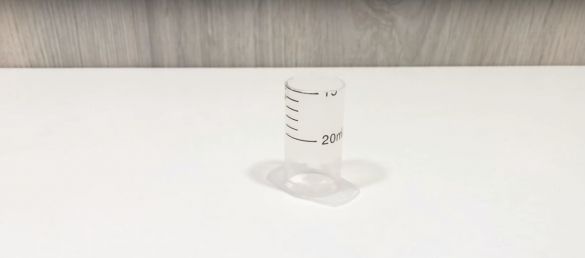

- a medical syringe (a 20 ml syringe is used in this homemade product);

- insulated copper wire with a diameter of 0.45 mm and a length of about 5 m;

- copper wire with a diameter of 2.5 mm;

- Neodymium flat magnets 2 pieces;

- a board for the manufacture of a wooden base;

- hot glue gun;

- a tube of super glue;

- a 9-volt crown battery.

Let's start by making the foundation of our engine - the electromagnetic cylinder. Let's make its body from a medical syringe with a volume of 20 ml. Such a syringe can be purchased not only in a pharmacy, but also in service centers or stores that sell and service office equipment. Employees of such centers use syringes to refill inkjet printer cartridges and, as a rule, syringes of the required volume are used mainly, namely 20 ml. We take the syringe and the first thing we take out the piston, it will not be needed. Using a hacksaw, cut off part of the syringe (15 ml division serves as a label).

We remove the excess aside, and we will continue to work with this workpiece.

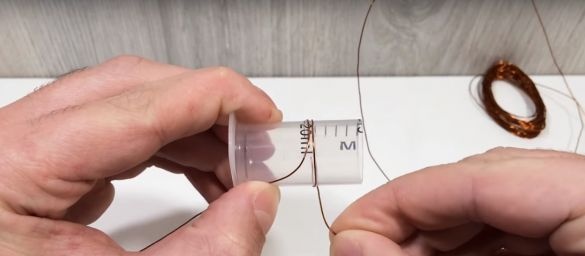

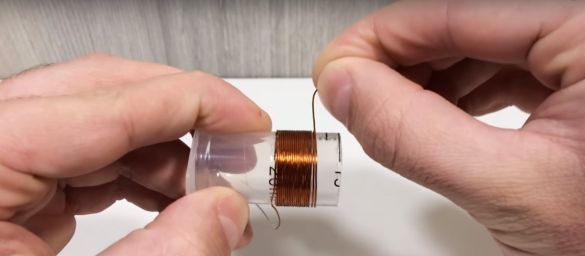

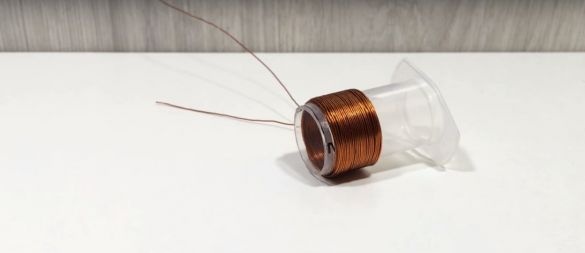

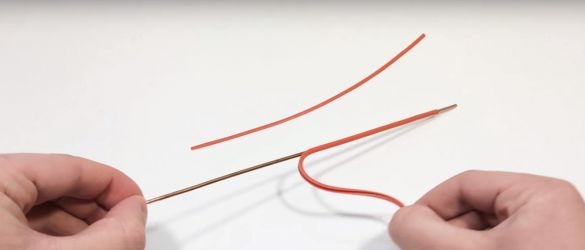

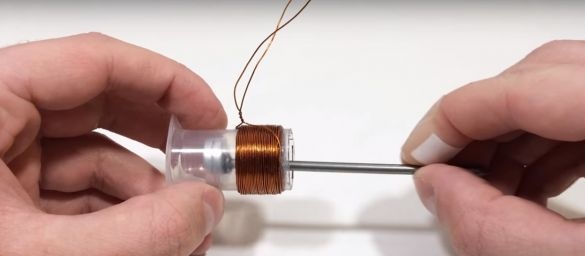

Next, you need a thin copper insulated wire. In this homemade product, a wire of 5 meters in length with a cross section of 0.45 mm was used.

It must be tightly wound in one direction in several layers on the cylinder obtained from the syringe.

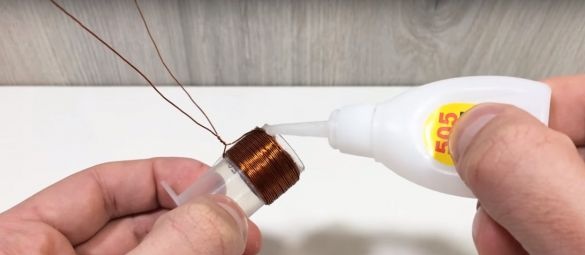

The ends of the wire are twisted together in this way. We fix the winding with superglue.

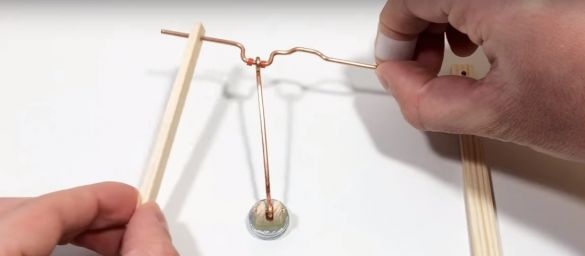

Then you need a thick copper wire from which we produce a crankshaft and connecting rod.

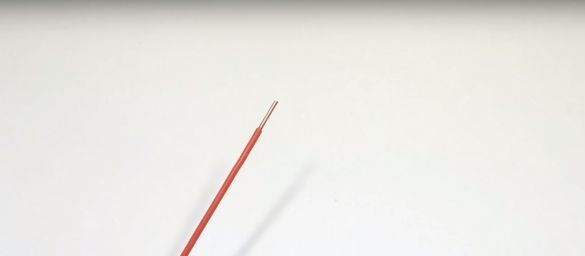

First remove the insulation.

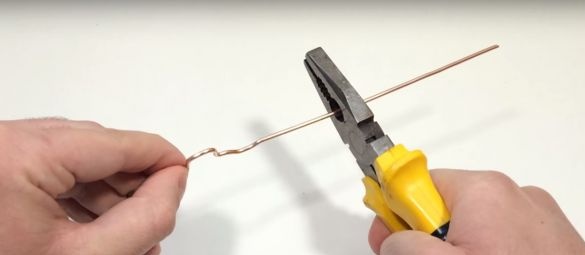

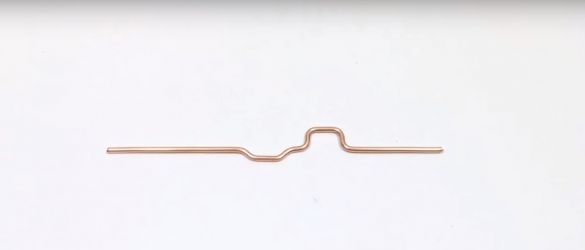

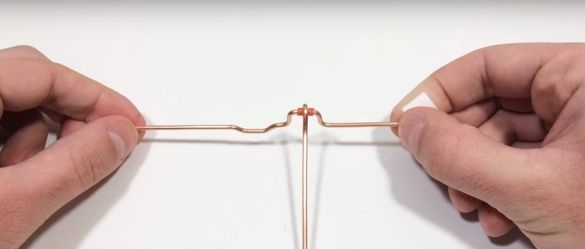

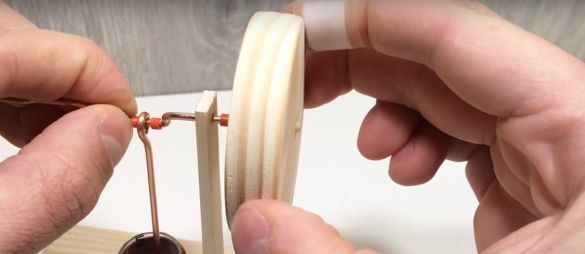

Next, using pliers, we give the wire the shape of a crankshaft.

From the remaining part of the wire using pliers we will make the next part - the connecting rod. For its manufacture, it is necessary to bend the wire from both ends as shown below.

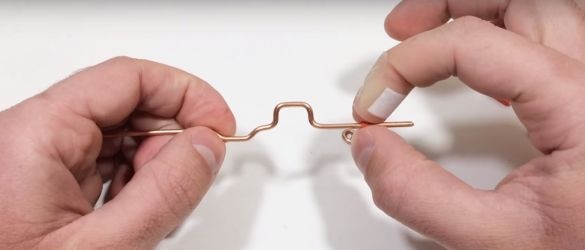

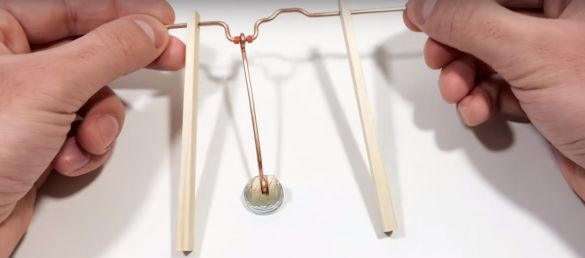

Then we connect both parts (connecting rod and crankshaft) together. To fix the connecting rod on the crankshaft, two pieces of insulation from the copper wire from which these parts were made are used. First you need to put on one piece of insulation, then a connecting rod, and then another piece of insulation.

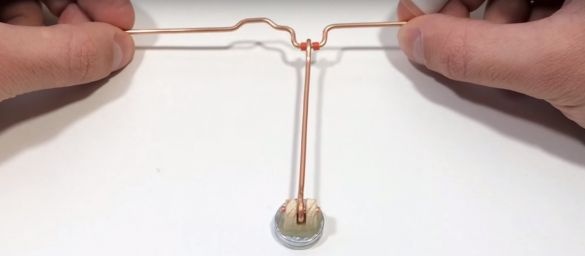

Next, you need two neodymium magnets of such a diameter so that they can easily move inside the cylinder.

And you will also need a part of a similar shape (it can be made of wood, for example), which we fasten to magnets with hot glue.

Then we fix the resulting part as follows:

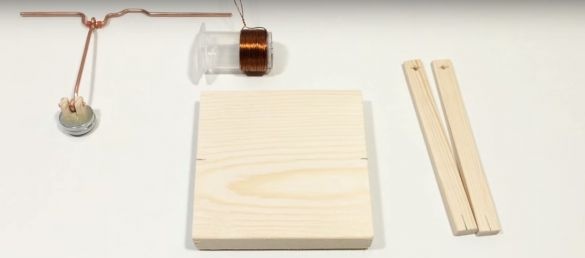

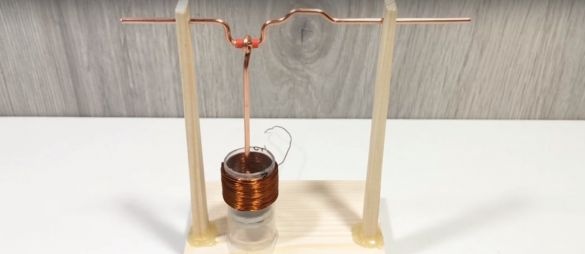

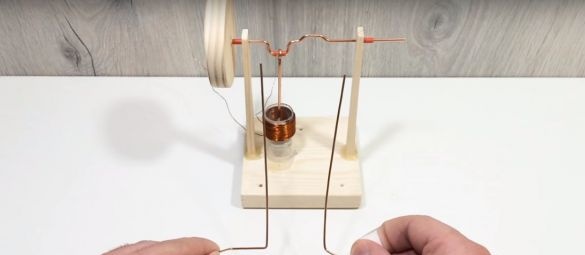

Then you will need a wooden base and two wooden support posts. These structural details can be made of any material, the main condition: it should not conduct electric current. But I believe that this design is easiest to make precisely from a piece of wood (in this case, boards), since wood is a very affordable material and quite simple to process.

Based on this, we outline the future location of the cylinder and support legs. Then we fix the cylinder with hot glue on a wooden base blank.

Next, insert the crankshaft into the support pillars. Then we fix the racks on the base with hot glue according to the marking.

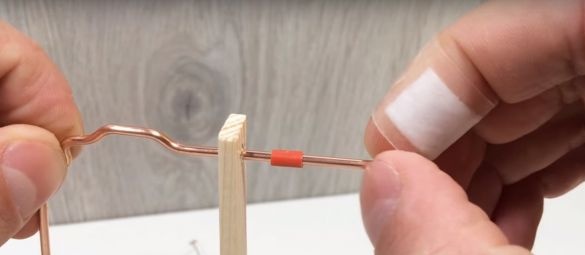

Then using small pieces of insulation we limit the movement of the shaft in the support posts.

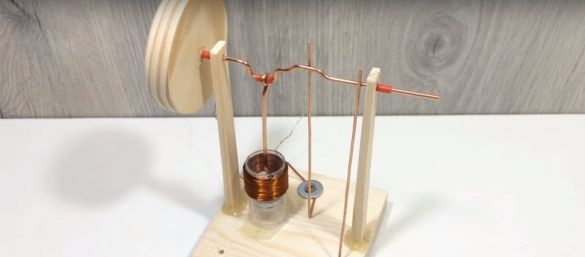

On one of the sides of the crankshaft we install a flywheel. It will provide smoother engine operation.

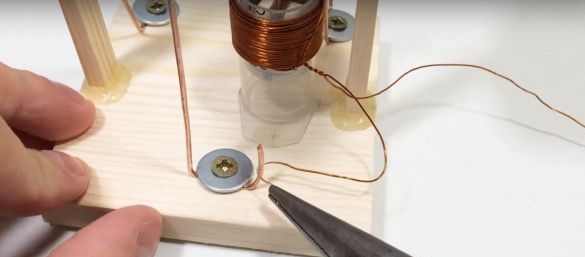

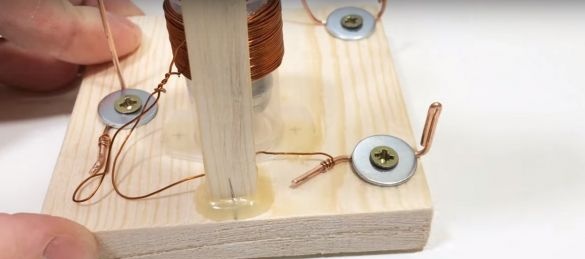

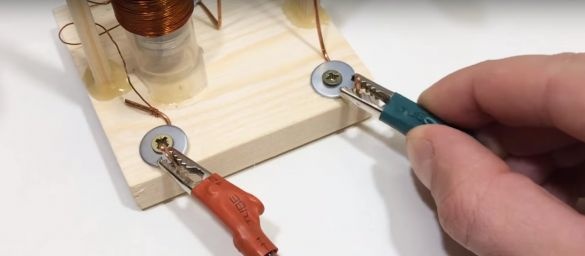

Then, you will need two contacts made of copper wire, which must be fixed to the base with a wide washer screw.

Then we connect the cylinder winding to the contacts. Before connecting, the ends of the winding must be cleaned of insulation (varnish).

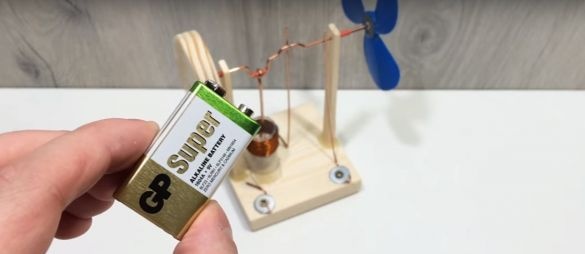

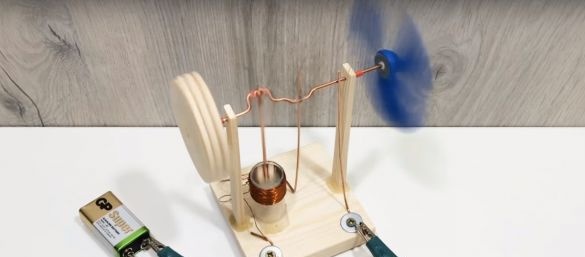

Well, the electric motor is ready. Let's start testing.

Using clips of the type "crocodile" we connect the motor contacts to the battery.

That's all. Thank you for attention.