IN home occasionally there are cases in the workshop where, in the manufacture of a part, it becomes necessary to process or modify a surface that cannot be reached with universal equipment. So the part may turn out to be bulky, brittle or not rigid, there is no way to fix the part or surface refinement in place is required.

For this case, manual device with flexible shaft and mechanical rotation of the cutting tool. The device is called in different ways - an engraver with a flexible shaft, a mini-drill, a drill, etc.

This device, resembling a fountain pen with a rotating removable processing tool, is connected by a flexible shaft to an external electric drive. Hand engraver, used in conjunction with a flexible shaft, allows you to process hard-to-reach spots on any product.

This device is universal, because, using a set of different tools, it can be milled, ground, polished, engraved and cut material, drill holes of small diameter, clean surfaces. Equipping the device with the appropriate working nozzle, it can be successfully used for work on ferrous and non-ferrous metal, wood, bone, stone, glass, ceramics, plastics and other materials.

Although it is not difficult to purchase such a device in the modern market, many do otherwise and make an engraver do it yourself. A homemade device will cost inexpensively and will not cause any special problems in manufacturing. Despite the simplicity of the design, a home-made engraver allows you to successfully perform the same operations as the engraver of the serial model.

To make a simple but easy-to-use functional engraver, you need accessories.

- Flexible shaft (located on the farm or purchased).

- A working nozzle (survey or manufacturing).

- Two ball bearings with a diameter of 22 x 8 mm.

- Drive engraver.

- A set of tools with which the processing will be performed. For a homemade working nozzle, any tool with a shank diameter of 1 to 3.5 mm is suitable.

Flexible shaft

The flexible shaft has increased torsional rigidity and low bending. A special cartridge is attached to one end of the flexible shaft. It is equipped with the simplest collet clamp, which is used as a mounting mechanism for nozzles that are easy to remove and install. The other end of the flexible shaft is connected to the electric drive by means of an adapter sleeve.

Flexible shaft can be purchased at

However, as a flexible shaft for the engraver, it is possible to use the drive shaft from the drill or the shaft for the speedometer of a car or motorcycle. We use this option for our homemade.

Due to the flexible shaft, the device has the advantage. During the operation of the device there is no excessive load on the hands. This is due to the fact that the shaft head is several times lighter than a power tool with an integrated drive.

Production of a working nozzle

The body of the working nozzle, in the clamping mechanism of which the cutting tool will be fixed, can also be used from a drill or made independently. In our case, it is made of steel (I used the services of a turner - a neighbor in the garage) This option has its advantages - strength and accuracy, but the cons - more weight. Due to light loads, it is possible to make a case of non-ferrous metal (for example, lighter aluminum alloys) or of a PCB bar by drilling a stepped hole for bearings in its inner part and treating the outer contour of the housing under your hand for convenient holding.

The threaded part of the case is designed for its connection with the used flexible shaft of the speedometer and corresponds to it in thread. In our case, it is M18x1.5 10 mm long. A housing 70 mm long is bored for two ball bearings with a diameter of 22 x 8 mm.

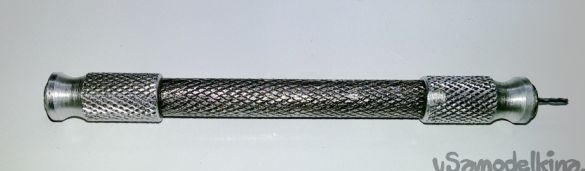

As a drive shaft with a collet clamp, which will be installed in the case, we use double-sided hand tools with interchangeable collets, sometimes used to drill holes in the boards. It's time to mechanize this tool.

The outer diameter of the tube (handle) of the tool body is 8 mm, slightly increased during the corrugation knurling operation. Thread collet screwed into the tool - M6. We disassemble the tool and complete the assembly with two ball bearings.

On the width of the bearing, for its tight fit, we clean the corrugations from the edges of the tube. We press the bearing on one side. To fix the shaft when clamping the cutting tool in the collet, we select a sleeve of suitable size, install it in the middle of the tube and fix it with a pin. We drill through the installed sleeve, in diameter, a through hole of 3.5 mm to install the stopper when clamping.

In the threaded hole of the instrument tube, on one side (instead of a collet), we screw a piece of a copper tube with a diameter of 6 mm. To do this, at one end of it, pre-cut the M6 thread, and gently squeeze the other end until the square fits tightly on the output end of the flexible shaft of the speedometer. As a result, the total length of the drive shaft must match the length of the housing.

Press the second bearing on the other hand.

We measure the distance from the front end of the tube to the hole for the stopper. The assembled shaft is installed in the housing, all the way to the rear wall. Mark the location of the locking hole on the housing. We remove the drive shaft and drill a locking hole in the housing. Having greased bearings we collect a working nozzle. Check the alignment of the holes for the stopper. If the bearings are unprotected, we cut and install, on the collet side, a protective washer made of plastic or felt.

After complete assembly of the housing of the working nozzle, the open end of the drive shaft should coincide with the end of the housing, and the crimped end of the copper tube should be flush with the threaded end.

We install the collet of the desired size.

We fix the flexible shaft on the body.

To secure the cutting tool

use the drift as a stopper.

Tool

As tools that turn a compact engraving device into a multifunctional processing device, the following are used:

- drills, with the help of which the engraver turns into a mini-drill;

- milling cutters of various designs, allowing the processing of flat and shaped surfaces, as well as holes, grooves and recesses of various configurations;

- disk tools used to perform cutting operations on materials of small thickness;

- metal brushes, which are used to clean the treated surfaces from traces of corrosion and other contaminants;

- abrasive tools with working heads of round, semicircular, oval and cylindrical shapes, used for grinding and polishing surfaces;

- tools with a conical shape working head for applying inscriptions and patterns to the surface of the workpiece;

- tools, the working head of which is made of felt, for polishing operations.

Rather high-quality milling cutters for engraving plants can be made from broken drills, if you give their working part the desired configuration using a conventional grinder.

Fixture drive

A drive electric motor, which can be used as any motor operating from an electric current of 220 volts. It can be the engine from a washing machine or other household appliances you do not use.

The electric motor from the sewing machine is optimal for a home-made engraver, since it is possible to regulate the speed of rotation of the shaft in a fairly wide range. Such engines, as a rule, are capable of developing a shaft rotation speed of up to 6 thousand rpm, which is quite enough for a household engraver. It is better to work with soft materials at slow speeds, since a high speed of rotation will entail overheating of the tool or fusion of the edges of the workpiece. At medium speed, it is recommended to work with metal. It is best to process hard natural stone at maximum speeds.

As a drive for an engraver, you can use a grinder with a “flying” gear, a drill or a screwdriver.

Such a temporary application is also possible.