Today we will focus on heating.

Is it possible to independently assemble a heating electric boiler in home conditions?

Of course, but for this you will have to use some devices and materials that not everyone has. Therefore, if you want to make a similar device yourself, most likely you will need to visit a hardware store, as well as a small household appliance store.

What will be needed for manufacturing?

1. Induction tiles with a power consumption of 1 kW

2. Heating radiator. The author used bimetal (aluminum can be used). Choose the number of sections depending on the area you need to heat. In this article, as an example, a radiator consisting of 4 sections is used.

3. Metal corrugated hose (eyeliner for the bath), you need at least one and a half meters, you need to take with a margin

4. Fitting and couplings

5. Copper tube

The author used induction domestic stove as a heating source.

Let's briefly review the principle of operation of the induction cooker.

Inside such a device is not a heating element, but an electromagnetic coil. If a current is passed through the coil, a field appears. If a metal object is placed on top of the coil, currents will appear in it. In order to be able to burn like this, it must be high-frequency, this means quickly changing direction back and forth. Such a current will create heat. The reverse side of this technology is a powerful electromagnetic field. Near some induction cookers, microphones work poorly or even stop working. Does induction cooker harm human health? Let's get it right. At a very close distance from the electromagnetic coil less than 10 cm, the electric field intensity will be approximately 137 V / m. If the fixed electromagnetic field is placed at a distance of 50 cm, then the field intensity weakens and does not exceed 18 V / m.

The conclusion is as follows: with such a stove you should not hug and everything will be OK.

Induction heating undoubtedly has one, but quite significant advantage over conventional heating (heating element). The main criterion is of course efficiency. Another undoubted advantage is the possibility of a longer service life.The heating elements used in ordinary household tiles, the so-called tena, quickly fail. Most often, they simply burn out. During the operation of such tiles, it sometimes becomes necessary to replace the heating element with a similar one. The electromagnetic coil used for the production of mainly domestic electric stoves is much less likely to fail or not at all during the entire service life of the product. This article will discuss how to make a fairly simple induction heater. According to the author, the manufacture of such a device will not take you much time. The author also assures that with such a heater having a capacity of about 1 kW it is possible to heat a room with an area of about 30 m².

Absolutely every induction hob has a power regulator. With its help, the heating temperature of the radiator will be adjusted.

First, the author makes an impromptu spiral using a corrugated metal hose with a diameter of 20 mm. It is made of stainless alloy, you can purchase one in almost any hardware store. It needs to be minimized as shown below.

It is necessary to obtain a spiral consisting of at least 4 turns. The author spent a little more than a meter of eyeliner on its production.

The hose bends very easily without the use of special tools, just with your hands. The diameter of the spiral circle should slightly exceed the area of the heating surface of the tile. For the design to work, it is necessary to make the jumper circuit. Firstly, this will add rigidity to the structure, and secondly, the induction hob will begin to perceive it as normal dishes intended for use on tiles of this type. Without this sealing, the induction cooker will not see such a spiral and simply will not turn on and the whole device will ultimately not work.

Therefore, this is a very important part of this design. The author made such a jumper using a copper tube soldering it in this way to a metal hose. According to the author, there should not be any difficulties in the manufacture of a spiral with a jumper connecting its circuit. He himself collected it in about 1 hour. The result was a closed loop and all the induction power will be used for heating. Water will circulate inside the hose. Therefore, induction will work on its heating.

Home-made induction boiler is almost ready. In fact, it consists of only two elements, from the induction cooker bought in the store and made do it yourself in a spiral.

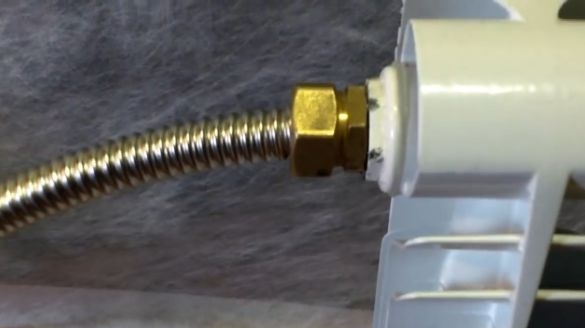

Next, you need to connect the circuit to the battery. Using fittings we connect parts.

The curl must be placed on the tile.

Next, the author proceeds to pour water into the radiator. Water itself will circulate in the heating system. No additional pump required. Hot water will rise up and fall as it cools down, where it will again fall into the spiral and will again be subjected to heating, and so on indefinitely.

In order to fill the system with water, unscrew the plug on the radiator. It is not necessary to fill the radiator to the brim, it must be borne in mind that when heated, the water expands.

Since this design does not have a special expansion barrel, the radiator itself will play this role. That is why when filling it, we leave a little space.

So, we begin to check. You must enable the tile.

First, set the minimum possible power, and then, as necessary, already set the maximum.

The author posted the sensor electronic thermometer on a heating radiator. The numbers quickly began to change quite quickly, increasing in accordance with the elapsed time of the device. During the test, it turned out that four sectional radiator batteries were not enough for an induction cooker with a capacity of 1 kW. The temperature of the heating system grew rapidly. Such a tile will not be difficult to heat a radiator consisting of a much larger number of sections (10 or 12 for example).According to the author, for the normal operation of this heating unit, in order to avoid overheating and boiling water, a radiator with 12 sections is required. This is if an induction coil with a power not exceeding 1 kW is installed in the tile. The author also talks about dividing such a battery into 2 parts of 6 sections each.

Also, this device can be adapted (in addition to being used as a heating boiler) for other needs, for example, it can be used as a water heater (boiler).

The advantage of this design is the ability to use the tile for its intended purpose - for heating or cooking. To do this, you just need to carefully remove the tiles from under the spiral. The design does not suffer in any way, it has sufficient rigidity.

We finished the kitchen affairs, put the tiles under the spiral of the boiler and that's it, you can turn on and operate the appliance.

On more expensive models of induction cookers, you can set a specific heating temperature and the device will maintain it itself.

The author of the homemade work took up the calculations and came to the conclusion that the approximate efficiency of his invention when compared with a heater in which a heating element is used as a heating element, turned out to be about 3.5 times higher than the efficiency of a heater with a heating element. The author used such a heater when it was quite cold outside the window (the thermometer showed -15 ° C), while in the room in which the home-made induction boiler was used as a heating system, the air temperature was about + 20 ° C. Based on the obtained practical test, it can be stated that this design has a place to be and is even more economical in terms of electricity consumption.

Roller: