Plastic bottles have firmly entered our lives. Water, drinks and even milk are being poured by more and more manufacturers into plastic containers. On the one hand, it’s convenient, plastic is lightweight and does not break, on the other hand, mountains of plastic containers clog the space around us. A good way to reduce the onset of plastic on nature is to recycle it. Plastic bottles make feeders, decorations, tables, chairs and even whole houses. The master decided to make a brush out of the bottles. Let's watch a short video.

To make a brush he needed the following

Tools and materials:

-Plastic bottles;

-Knife;

-Rule;

-A device for cutting strips of PET bottles;

-A device for straightening strips;

-Wooden frame;

-Electric furnace;

-Scissors;

-Board;

-Plane;

-Pencil;

- Clamps;

-Drill;

- Hacksaw for metal;

-Vise;

-Wooden skewers;

-Glue;

-Tool for grinding;

-Olyfa;

Step One: Cutting the Strip

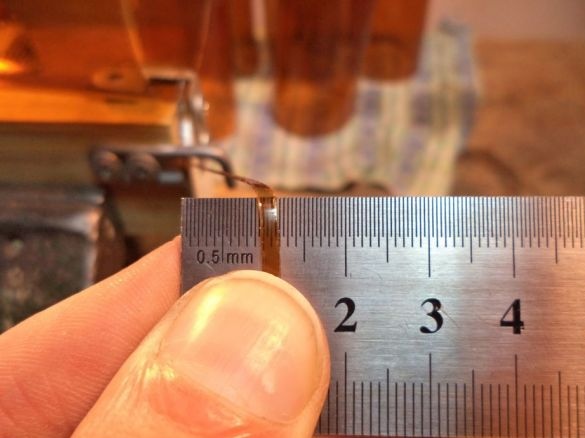

To make one brush, the master needed eight bottles. Dissolves bottles in strips. The width of the strip is 2-3 mm.

Step Two: Strip Processing

If you look closely at the bristles on the brush, you will notice that this is not quite a strip. The bristles are more like a straw. The master achieved this form by processing the strip. For processing, the master made a special device. It consists of a bar and two wires attached to it. Two wine corks are screwed in the middle of the bar. A coil with a strip is mounted on the wire. The strip extends between the two plugs and then into the ring of the second wire. An alcohol burner is installed under the strip. Then the master extends the strip and the ends of the strip, passing over the burner, are twisted into a tube.

You can see this process in detail.

After processing the strip, the master wraps it on a wooden frame.

The frame with the strip is placed on the stove for 30 seconds on each side.

Step Three: Bristle

Now it remains to cut the strip in half and the bristle is ready.

Step Four: Foundation

For the foundation, the master took two tablets. One larger board will be a pen and a second board with a bristle will be fixed on it.

Step Five: Install the bristles

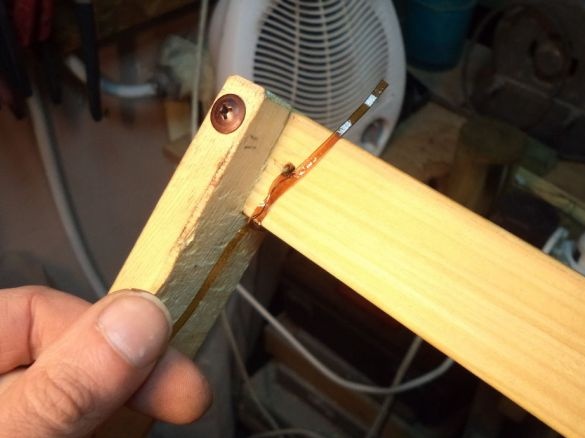

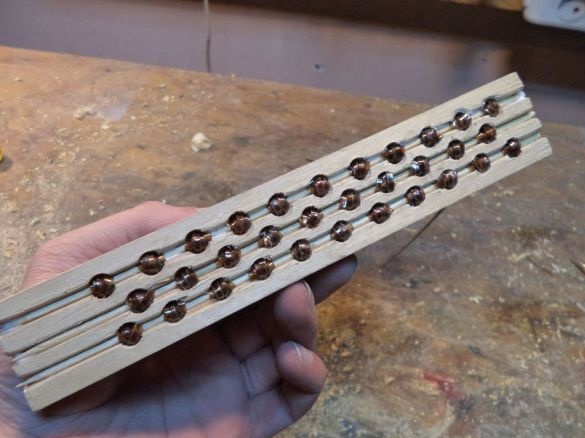

In a smaller bar, marks and drills a series of holes.

A hacksaw makes cuts between the holes on the one hand.

Cuts skewers along the length of the base.

Installs bristles in the holes. Then it puts glue on the skewers and stretches the bristles down to the stop.

Step six: gluing the base

Glues two parts of the base of the brush.

Seventh step: grinding

Sanding the wooden parts of the brush.

Step Eight: Trimming

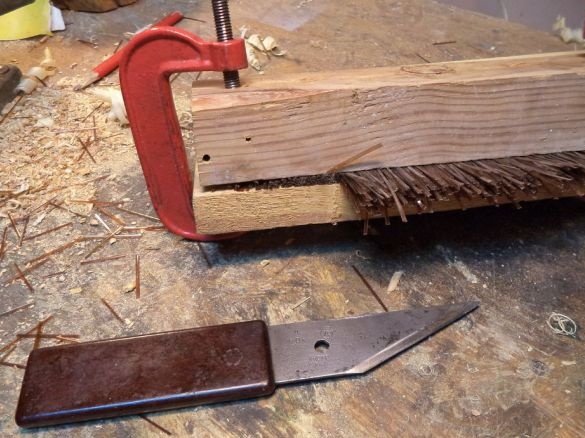

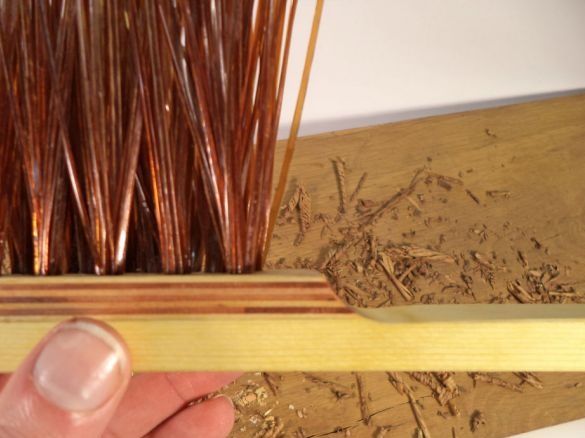

Clamps the bristles of the brush between two bars. Trims off excess bristles.

Step Nine: Cover

Covers the brush with drying oil.

Sweeping brush is ready.

Subsequently, the master made another brush with a long handle.