Today we will create a complex silicone mold for reusable castings.

To do this, you will have to plunge into some interesting subtleties. Taking casts opens up enormous opportunities for homemade products of various kinds. Usually, to make an impression of a figure, you need to make two halves. One half is covered with sculptural plasticine, and the second is filled with silicone.

Then they remove the plasticine and again pour the silicone into the vacant half. Thus, you can make casts of excellent quality.

But what if the whole figure is made of sculptural plasticine.

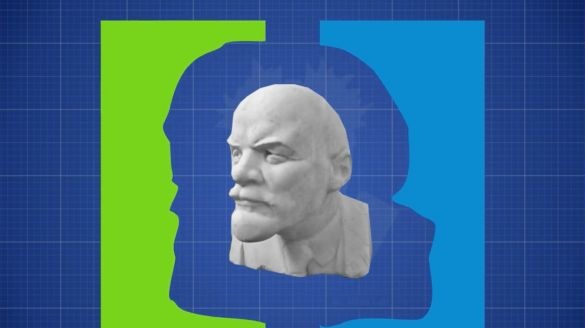

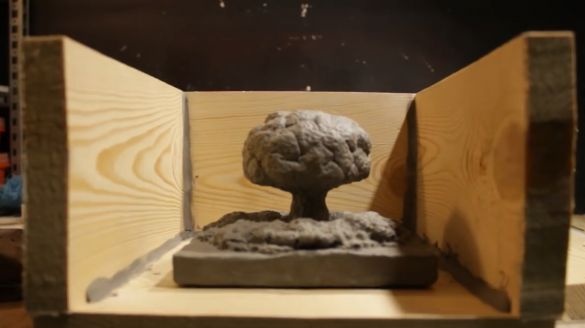

No, this is not a tree, not a mushroom, or even broccoli. it model atomic explosion from the largest bomb in the history of mankind AN602.

The author tried to mold this model more or less similar in shape to the explosion. We will make a cast of it. Then to cast it from epoxy.

Everyone loves explosions and it’s nice to have such a small glowing atomic explosion on your table.

Materials and tools:

1. Silicone

2. Vaseline

3. A pair of boards

4. Screwdriver and screws

5. Knife

6. Pliers

7. Plastic caps

8. Sculptural clay

When taking an impression, it is very important to think about how the model will be positioned so that it does not happen that when pouring silicone, it cannot fill in some areas. Or in the future when you pour plastic, epoxy, gypsum, wax or something else into the mold, there should also not be a place where air cavities can appear, into which the composition simply cannot get.

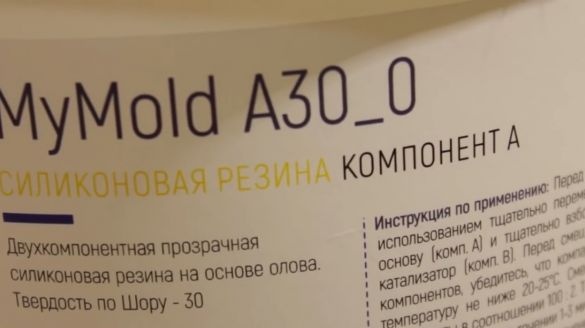

For this purpose, the author bought a bucket of deshmansky Chinese silicone and, probably, it is the cheapest silicone of all that exist. Hardness thirty. That is kind of like medium hardness. For collapsible forms, what you need.

The silicone layer around the figure should be at least two and a half centimeters.

You have to pound a box of a suitable size.

All seams must be covered with plasticine, otherwise it will leak.

Silicone does not leak much, but still unpleasant. In the upper part, the model is much narrower than at the base. You can’t leave it like that, otherwise a whole kilogram of precious silicone will leave. Therefore, the bars had to be filled. Unused corners and nooks can also be covered with plasticine in order to save.

To make it easier to peel silicone from the tree, all walls must be carefully treated with petroleum jelly. Where without him.

In order to fix the model inside the formwork, we will use self-tapping screws. Plasticine

sculptural, not very soft and holds its shape well. So, in principle, it should be a ride. In order to know what height to fill in and not to guess then it is flooded a lot or a little, you need to roughly indicate the desired level with a pencil.

Now silicone. It happens with a tin hardener, and it happens with platinum. Tin is naturally cheaper and more unpretentious.

Rumor has it that silicone interacts poorly with plasticine and may not polymerize. In this case, the clay begins to melt and the model can then be thrown out. To save your nerves and not worry about this, just pour a little silicone into a mold from the same plasticine as your model. After some time, see what happens. Most likely everything will be fine and there will not be any stocks.

If silicone does not want to harden, then you need to cover the clay with a layer of petroleum jelly. Or, as an option, purchase special aerosol separators. They are sold in the same place as silicone.

Having estimated the necessary volume of silicone, taking into account the fact that it also spreads over the container when stirring, the author decided to prepare one and a half kilos. When mixing with a hardener, you need to mix it very carefully, manually, so as not to blow bubbles into silicone. Usually, even if bubbles appear, they, in principle, come out of the mixture well. But not in our case. Chinese silicone grabs air just like before death. Even with light stirring, a bunch of bubbles appear inside. The author tried to do degassing using a small vacuum pump.

The process went, bubbles came out. But this volume is too large for such a pump, and silicone cannot be kept idle for a long time. Need to pour. Pouring must be done slowly, carefully, so as not to touch the jet model. Otherwise, you will have to cut off the excess silicone from it before pouring the second half.

Now you need to make the locks. After all, the form will be collapsible, which means it must be clearly docked. The author suggests using such plastic caps.

Plastic is lighter than silicone, but not by much. Before pouring, you need to experiment. Mix a little silicone and pick up something suitable that will not sink completely and will be easily removable. We press plasticine inside the caps to make them heavier.

But not so much that they drowned completely, but that they stick out slightly from silicone. You need to place such locks as often as possible. There will be no excess - that's for sure.

After the silicone has completely hardened, you can pull out the caps and cut off the protruding burrs.

When pouring the second half, silicone will be poured into the resulting recesses and locks will be obtained that will help to precisely join the two halves.

Next, lubricate the surface of the silicone with Vaseline, so that the next layer does not stick to it. Finally close the formwork with the last board. Then pour the silicone to the mark previously outlined with a pencil.

To better wet the silicone and release the gases, it can be slightly vibrated with a spoon.

Now you need to wait until the second half hardens completely. This should take about 16 hours at room temperature. In general, specifically this silicone sets in an hour, but gains full hardness in almost a day.

The silicone remaining in the container polymerized, but not completely. As usual at the bottom and in the corners, mixing silicone with the hardener does not work well. He remains forever sticky byaka.

Therefore, it is better to use disposable tableware for kneading. Or that which is not a pity. But if you managed to knead silicone in your mother’s favorite wife’s favorite cup, or God forbid mother-in-law, then you definitely have to wash it. In principle, like hands. Ordinary soap, to be honest, crap sucks. More precisely, it does not wash off silicone at all. Most of the silicone on the dishes and hands can be wiped off with rags. And with the remaining silicone, a hand cleaning paste handles well.

This paste is a kind of concentrated soap mixed with fine abrasive. He scrapes all the silicone and prevents it from sticking again.After wiping the cleaning paste, just rinse all the silicone with water. And no solvents or any other cleaning agents are needed.

Well, you can disassemble this miracle box. Any excess sticking pieces, immediately cut. You can see how the silicone has leaked through a small gap.

Even after smearing with Vaseline, the wood does not want to stick. We have to make efforts to separate the silicone. The halves stuck together quite strongly, but still served. Plasticine, even without vaseline treatment, does not adhere to silicone at all. The model was absolutely not damaged. Except for small mechanical jams that are easy to fix. This method of making copies was very sparing.

Despite the large number of bubbles in silicone, the impression seems to have turned out without noticeable jambs. But only after pouring it will be visible what actually happened. The mold is covered with roughness due to the fact that the surface of the plasticine was not smoothed before pouring.

Perhaps, after all, it was worth going with a brush with a solvent to remove too fine a texture from the surface of the model.

Let's try to dock the two halves.

They fit perfectly together. Almost no junction line. Even when pressed, the two halves move as one. As if there was no junction at all.

The sides specially left the sides flat so that it would be more convenient to fix the two halves before pouring, pressing them on both sides with two pieces of the board. It is not necessary to compress strongly, but at least slightly to hold. Epoxy tends to flow through any cracks. So let's see how she behaves.

It is desirable to store the form in assembled form, so that if it suddenly leads, then even if it is evenly deformed.

Well, the silicone brick is ready.

Thank you for attention. See you soon!

Video clip: