Hello, dear visitors of the site. Today I want to talk about how easy it is to make feather drills on wood.

The other day I needed to drill holes of large diameter in the chipboard, namely 40 and 20 mm. And then it turned out that I did not have the right drill !!!

No ... Of course I have many different feather drills. And ordinary and somewhat adjustable. But, the trouble is that I was working at home in the basement right now, and my drills are on the other side of the city, namely, at the construction site where I used them for the last time ...

And so I decided to quickly make the necessary drills from what was at hand ...

And, in fact, I needed the following for this:

1. a piece of sheet "stainless steel", 2 mm thick. (Not necessarily a "stainless steel" ... It's just that I was lying around ..)

2. A metal pin with a diameter of 10 mm. (You can also thinner ... It's just that I had this one))))

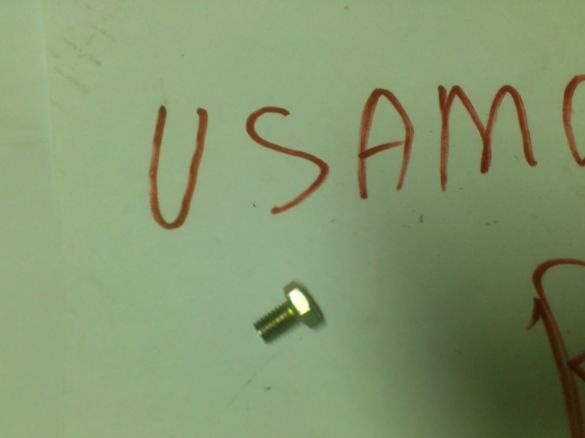

3. Bolt (screw) M6 (or thinner).

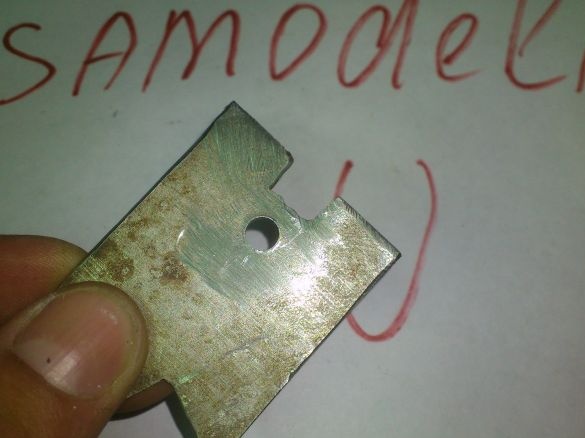

So, where did I start ... I found a piece of sheet metal, 2 mm thick. Caught on the arm here is such a piece of "stainless steel"

I started with a drill, with a diameter of 40mm. To start, I drew a blank of a drill on a piece of stainless steel:

Using a grinder with a cutting wheel, I cut the workpiece:

After that I made the core of the drill itself. I decided to make it out of a ten-millimeter bar that was lying in my scrap metal:

There was no thinner bar at hand ... But I thought that this one would do. After all, a rod of this diameter will go into any cartridge of a household drill. Of course, its thickness regulates the minimum diameter of the drill, but I always have drills up to twelve millimeters ... (These are metal drills, but they can be easily applied to wood). A feather need only large diameters ..

I cut a piece of the desired length from the rod:

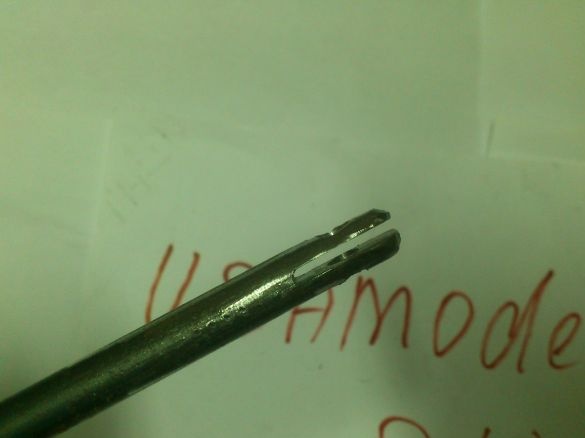

Clutching in a vice, I cut a diametrical slot in a cutting circle. I estimated the depth of the cut by eye, just attaching the blank and noting such a depth, "so that it was normal" ...))))

After that, I checked if my “feather” is inserted into the slot of the rod:

Aligning exactly in the center, I made marker marks on the plane corresponding to the thickness of the rod:

Then I made cuts along these lines:

Changing the cutting wheel to the cleaning one, I chose the metal between the slots.

Now you need to fix the feather in the rod. It’s easier, of course, just to “drip” welding. But, in order not to make the second rod (after all, I had to besides the forty-millimeter, also the twenty-millimeter), I decided to fix it with a screw. To do this, I drilled a hole in the rod, perpendicular to the slot. I used a drill with a diameter of 5 mm.

Then I drilled the upper half of the rod (to the slot) with a drill, with a diameter of six millimeters:

And in the lower half I cut the M6 thread:

After that, I inserted the pen into the shaft, aligned it, and, having marked the center with a drill, drew it and drilled a hole with a diameter of 6 mm.

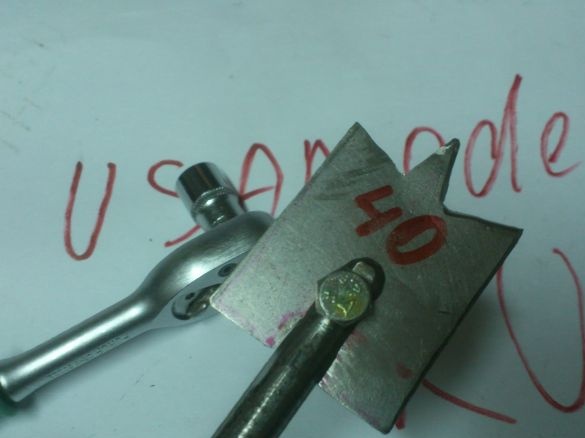

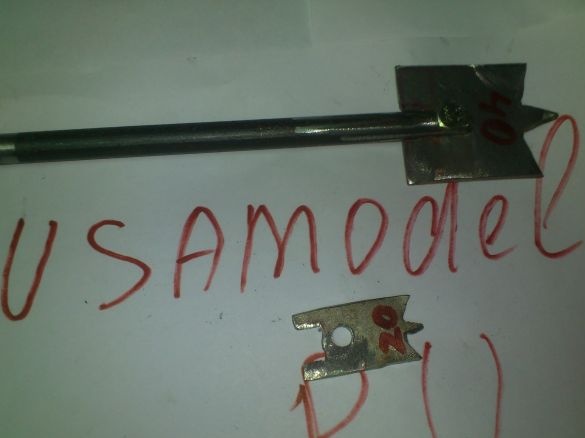

Now you can insert the pen into the shaft and fasten it with a screw:

In the role of a screw, I had an M6 bolt. It was easier for me to thread. But if you don’t have taps at hand, you can use it as a bolt - screw the nut on the other side. It will not hurt, just fixing will not be so convenient - you will need two keys ...

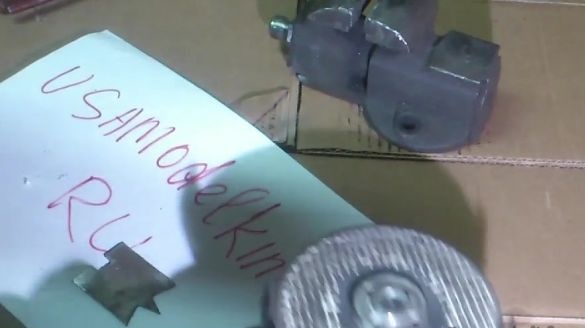

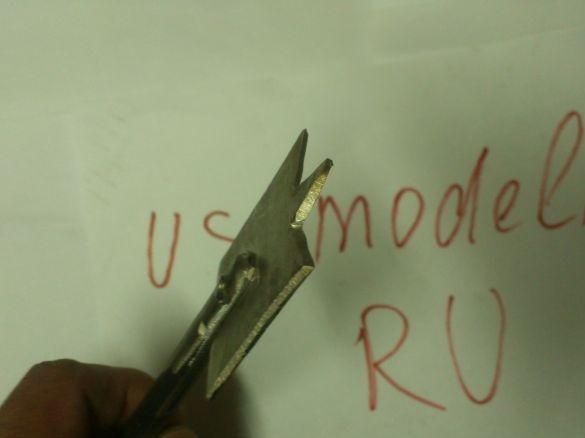

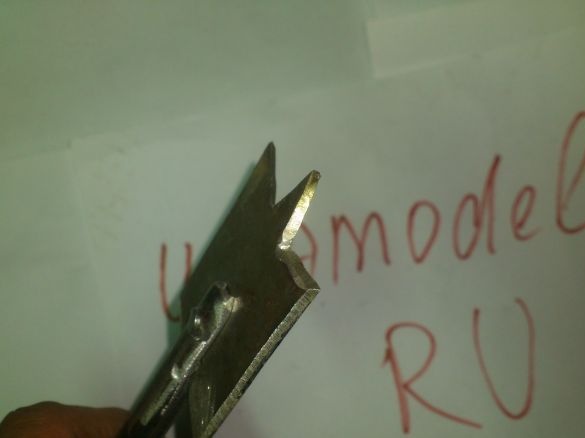

Now sharpen our drill. I used a homemade emery with a diamond cup ... Just because I had it at hand:

And you can imprison with anything, even a grinder ... There is no need to observe a certain angle. It should not be made too sharp just:

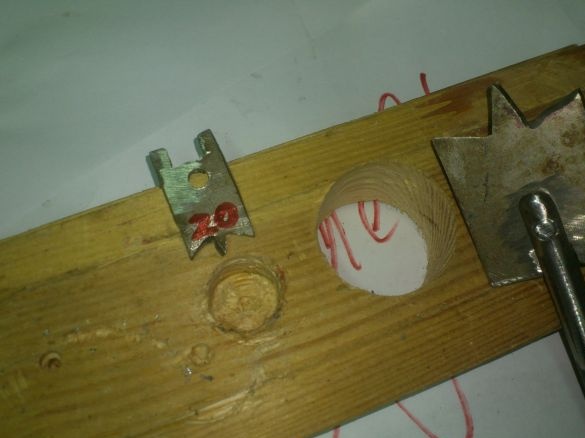

All! The drill is ready. It will easily enough drill both a tree and a chipboard:

Because the core was already ready, making a second pen, with a width of 20 millimeters, was not difficult:

Of course, such drills are not suitable for permanent, professional work ... For this we need purchased drills made of good steel ... But I'm not a professional !!! I am a master!

It took me about twenty minutes to make it. (During this time I would not go to the store even for him))). And the manufacture of subsequent diameters is half as much ...

And I did the work for them - I drilled the hole I needed. After that I will put it on the shelf, and next time I will need it .... maybe in a year ... Or maybe in five !!! ... (Or maybe it won’t be needed at all!)))) But he will no longer need to buy or do it ...)))

.. By the way, at a construction site, when I needed to fix beams and rafters, I also used just such a drill. At that moment I lent my friend a long drill on wood, and, as it usually happens, he didn’t return it to me in time ... And in order not to lose days, I lost minutes - I made the same drill, only half a meter long, and did the job ...

... For such purposes, such drills are very well suited !!!