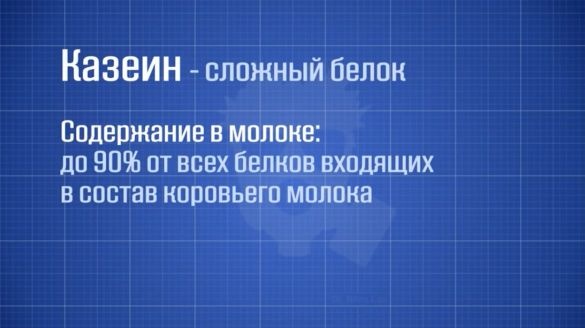

Milk is not only a nutritious healthy fluid, but also a source of casein.

This protein is used for many purposes, including the production of plastic and glue. Yes, milk is used to make real plastic called galalit. Almost like ice. In 1925, a whole factory for the production of this plastic was even built near Moscow. And on it they did not mold figures from dried cottage cheese, but made casein-formaldehyde resin. Casein is used to make glue, the mass production of which was launched back in 1800 in Germany and Sweden. There is also evidence that such glue was used in ancient Egypt. Today we’ll try to cook it, observing the technology if possible. So, the first thing you need is skim milk.

It is very important to take milk with the least amount of fat. The less fat, the better the glue. In 100 g of milk - 3 g of protein. Almost all of this protein is casein. It just needs to be separated. Well, although not quite simple. There is a special technology: milk must be heated to a temperature of 35 ° C. We will do this in a water bath, and constantly monitor the temperature. When the temperature has risen, you can add acid. In production, either lactic or acetic acid is usually used.

For a liter of milk, you need to take 5 ml of 70% acetic acid. You need to add it not immediately, but slowly. Add half a milliliter with a frequency of one or two minutes, and at the same time, continuously mix the milk.

When all the vinegar is added, the milk should be left to warm. The author did not manage to keep the temperature exactly 35 ° C. Sometimes she jumped to as much as 50, but it’s not scary, the main thing is not to heat strongly and do not pour in acid quickly, otherwise casein will start to form large flakes and this will worsen the quality of the final product.

The resulting serum must be drained, and the casein itself filtered. To filter, the author will use coffee filters. This is generally a cool handy thing. This is just a real find for the masters.

By the way, pay attention to casein grain size. They are more like very, very fine sand, and due to their size, they can be washed well from all the excess.

If there were large flakes, then flushing would require much more strength. To do this, filtered casein needs to be poured 3-4 times with a large amount of boiled water to wash off whey residues. Each time the author did not filter.He simply drained the dirty water, which he defended. Well, in the end, he filtered out casein and got just such a mass.

Honestly, she doesn't look like cottage cheese at all. Indeed, a lot depends on technology. Due to this small grain size, casein of very high quality can be obtained.

We’ll try to make glue from half of the resulting casein, and dry the second half to see how it will look after drying.

If there were 30 g of protein in a liter of milk, then it means we took 15 g of protein, as well as 90 g of water and 12 ml of 10 percent ammonia, that is, ammonia.

The fact is that ammonia creates an alkaline environment in which casein acquires the ability to dissolve in water. Instead of ammonia, you can add borax, soda or alkali. The essence, in principle, does not change.

After a short stirring, all casein dissolved, and it became like real glue.

I think many people are interested in the topic of composite materials. Let's test this adhesive for composites. To do this, the author took 10 layers of fiberglass and glued them with this glue. Also for comparison, he took three cotton pads and also glued them with this glue. He squeezed out the excess glue, maybe in vain, but then we'll see. Well, since this glue is used in carpentry, the author decided to check how he will glue two pieces of wood together. You need to generously spread and squeeze them together for at least 5 hours.

While the samples were drying, the author decided to prepare more casein, and took a half kilo of fat-free cottage cheese. In principle, this is the same casein, but without unnecessary hemorrhoids.

Did you know, by the way, that before there was no cottage cheese? All sour milk was called cheese. Even the Vikings took cheese with them on a voyage, because it does not deteriorate. Recent dna studies prove that one in 30 people is a direct descendant of the Vikings.

So, cottage cheese is almost the same casein. It only needs to be thoroughly rinsed. To do this, you will have to break the clots. Rinse should be the same as last time, with plenty of clean boiled water. Squeezing and filtering such a large volume through coffee filters is absolutely masochism. So it is better to use two layers of plain cotton fabric.

After all the cottage cheese is washed and squeezed well, it can be dried. The author set it to dry in an open oven on the smallest fire. After drying, these granules were obtained.

In dry form, they can be stored indefinitely and used when it is necessary to make a little glue.

The first samples have dried. First, check the cotton pads.

In general, in principle, for cotton wool, they were well glued. Disks do not fall apart into separate layers. It turned out some kind of cotton wool.

Fiberglass stuck together, but very quickly scattered into separate layers. They stuck together very poorly.

The trees seem to be normal, but still scattered.

Yes, not a very impressive result. Let's try using glue made according to a different recipe. To do this, grind casein in a coffee grinder. The resulting powder must be weighed and add exactly the same amount of slaked lime. It is sold in hardware stores.

The resulting powder is a finished glue. It can be stored in this form, and if necessary, diluted with water and immediately used.

For every 100 g of glue, you need to take 100-150 g of water, depending on how thick the adhesive you want to get. As soon as the mixture gets wet, a chemical reaction immediately takes place and casein turns into calcium caseinate. This caseinate is insoluble in water. Generally insoluble in water. It turns out waterproof glue. That is why casein should be used immediately, since it quickly loses its stickiness. Literally after 5 minutes it becomes slightly rubbery and no longer so sticky.

From the remaining glue, the author made a lump and left it to dry. To test the liquid glue again, he doubled the amount of casein in the glue. To dissolve it well, you need to wait 2-3 hours, or grind it well in advance. After that, he added another 12 ml of ammonia and it turned out this:

There is some kind of reaction. The glue becomes like a whipped cream. Here in a glass about 30 grams of casein, 15 ml of ammonia and 100 ml of water. And in all this we add 3 g of lime so that it sticks together more powerful.

Further, the author again glues 10 sheets of fiberglass, carefully expelling all air bubbles from under each layer. It also glues 3 cotton pads, also impregnating them well with glue.

Everything is dry, and it's time to check. Cotton pads have become much stronger, but the layers have dispersed. It seems to be the first time it turned out even a little better.

But fiberglass taped better than before. It is no longer scattered into layers, but breaks on a bend. This is even a bit like a composite, although far from ideal.

And here are the pieces of wood. The glue on them just petrified. The author dried it in a warm place for six hours without removing the clamps.

The glue is so hard that you can probably blunt the blade about it.

Well, a test for strength:

It turned out just some kind of wild superglue. If you glue a stool with such glue, then rather the stool itself will break, than this glue will disperse.

Here is such a superglue can be made from milk. There are a lot of different compositions of casein glue. Everything is simply unrealistic to try. Each is suitable for some of its purposes.

Thank you for attention. See you soon!

Video: