Most running glass - 3-5 mm. Glass is available in various sizes. It is necessary to take the sizes from the windows and buy such glass, the waste from which will be minimal. To measure glass, you need to measure the distance between the folds and subtract 3-4 mm from it, i.e. the glass will be slightly smaller than the gap prepared for it. This gap will protect the glass from overload when swelling wooden binders during rains. Prepare a shtapik in advance. It can be square (1x1 cm) or triangular section. Sew a bead and paint in the color of the window.

Glass cutting is performed with diamond or roller glass cutters. For those who have never cut glass before, it is better to use a glass cutter.

In construction, glass is cut on special workbenches studded with felt. We will do it easier. Find the door equally in the apartment, remove it from the hinges and put it on one side of the window sill, the other on the table. Remove the handle. So we got a well-lit workbench. Using a pencil and a ruler, draw several transverse and longitudinal lines on the door. Put glass on the workbench. Bring a frame that requires glazing, measure the distance between the folds at the top and bottom of the frame, subtract 3-4 mm from the gap. Now set the distances aside on the glass and cross them off with a glass cutter. Combine the marks received on glass with any of the lines drawn on a workbench.

A man with strong fingers holds a glass cutter like a pencil, others - holding the entire handle in a fist, with the cutting part down, with the thumb on top.

The glass cutter is placed perpendicular to the glass. The cut must be kept from edge to edge. The edges of the glass must be cut through. It is necessary to press the glass cutter strongly, but so as not to crush the glass. The cut line should have a clear trace and not be interrupted. If you are cutting for the first time, put a flat, ragged rail next to it and cut along it (like a pencil on a ruler).

Cut it! You need to cut it boldly, the glass of trembling hands does not like.

After making the cut, slide the glass onto the edge of the table so that the cut protrudes 2-3 cm beyond the edge, tap it from below with a glass cutter.You will see how the crack grows. Slide the glass so that the cut coincides with the edge of the table. With your left hand, press the glass to the table. Right, wearing a mitten, take the glass by the edge and press down sharply. It will break off along the cut line.

Experienced glaziers usually do without rail and without tapping. They have a simple scheme: marked out, put along the line, cut, moved to the edge of the table, broken off.

Glasses need not be afraid, this is a fairly durable material. Approach the glass boldly and it will obey you.

When you need to break off a narrow strip, do not break it with your hands, take the pliers. All work related to the transportation of glass (purchase, transportation, etc.) should only be done with mittens.

After you cut the glass and in height, you need to insert it. In wooden binders, glass is inserted on the putty and glazing beads (Fig. 15).

The bead is cut lengthwise with a knife or a hacksaw with a small tooth. Nails must be hammered with a light hammer. The hammer should slide on the glass. If you lift the hammer from the glass, then with an inaccurate blow it can be split.

Stump sections protruding above the frame are planed.

Putty glass is inserted in the same way. First, the folds are filled with a thin layer of putty. Glass is inserted and pressed 3-4 nails on each side. Then everything is again smeared with putty.

With a large amount of glass work, mark the frames and sashes with a pencil. Otherwise, you will be looking for a long time, from which window this or that sash.

How to transport glass? Glass is transported only in an upright position. With small sheet sizes and small volumes, I transported glass in a passenger seat in car. He set the glass, then he carefully sat down himself and pressed the glass with his back. Drove to a distance of 50 km.

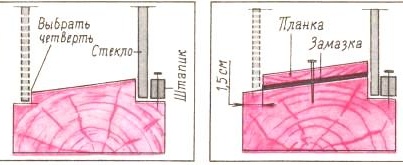

The window is a significant source of heat and loss. To keep warm in the house and reduce noise from the streets, you can make triple glazing. To do this, in the outer frame of the window you need to select a quarter of 1.5x1 cm (Fig. 16). A quarter choose a chisel. On a long section of the frame, a quarter can be selected with a manual circular saw. But the corners still need to choose a chisel. Or disassemble the frame. But there is another way. Just sew a quarter (Fig. 17).

Agree, it is much easier to trim the bar than to work with a chisel. The bar can be put on the putty layer to avoid blowing and nail with nails.

I foresee the objection of the masters - the sewn quarter is unaesthetic. And if a person has never held a chisel in his hands? He will choose such a quarter that it will become the "ideal" of aesthetics. So with the plank, perhaps, he’ll come out more beautifully.

With the second glass, the frame will be much heavier, so it’s not out of place to put metal window corners on the corners and add a third hinge.