When working in a workshop, sometimes it is necessary to use self-tapping screws, screws, screws, bolts, studs, anchors and other fasteners that have threads. But they are not always needed in their original form, form, because there are some new, non-standard ideas, solutions. And in such cases, the products we are used to need to be modified, brought to the desired state: file, cut the thread, remove the excess metal layer, adjust the size of the bolt head to a certain wrench, change the torn cross-shaped slot with a hacksaw to straighten it (to the screw could still serve) - there are many options for remaking. But in order to process the fastener, you must first securely fasten it, so as not to damage the thread when clamped in a vice. And it was for this task that I came up with not so complicated device. Tools and material needed a little. Here is a modest list of them.

Tool:

1) Ruler;

2) Pencil;

3) scissors;

4) Sandpaper;

5) Electric jigsaw;

Material:

1) fiberboard (wood - fiber board);

2) A bicycle camera (or other similar rubber material);

3) Thin rail 2 to 3 mm thick, 20 mm wide and at least 40 mm long.

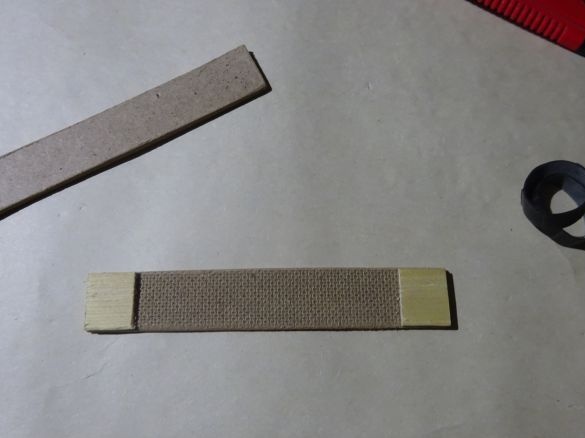

Step 1. We take a small piece of fiberboard and use the ruler and pencil to designate the dimensions so that we get two identical parts (for my vice this is: 16 x 2.5 cm), we draw.

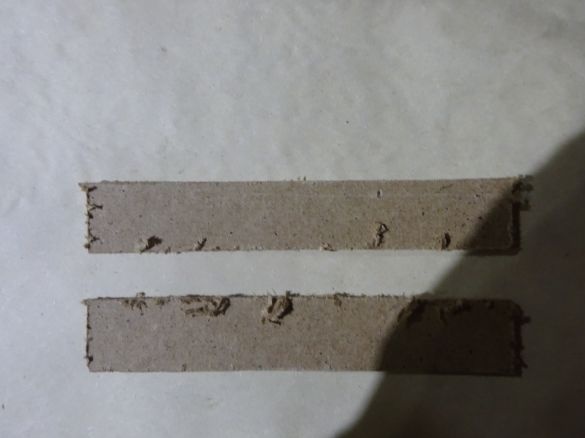

Step 2. Electric saw with a jigsaw along the marked lines.

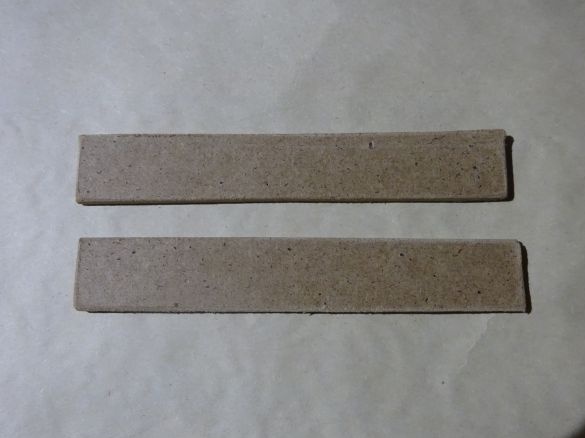

Step 3. With sandpaper we process uneven places after passing with a jigsaw to give a decent look to the workpieces.

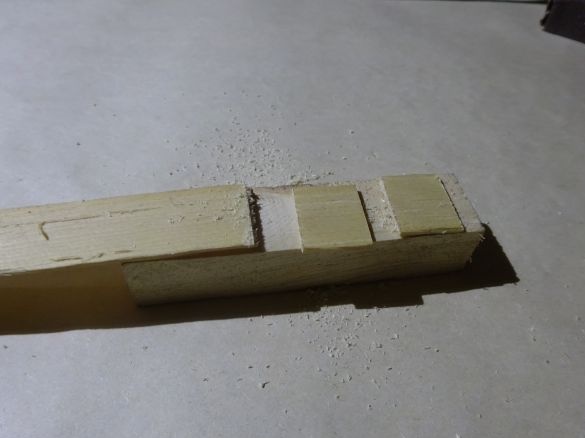

Step 4. We take the prepared rail and saw it into two parts measuring approximately 2.5 x 2 cm.

Step 5. Using stationery scissors, we cut the bicycle chamber into two rings with a width equal to about one centimeter.

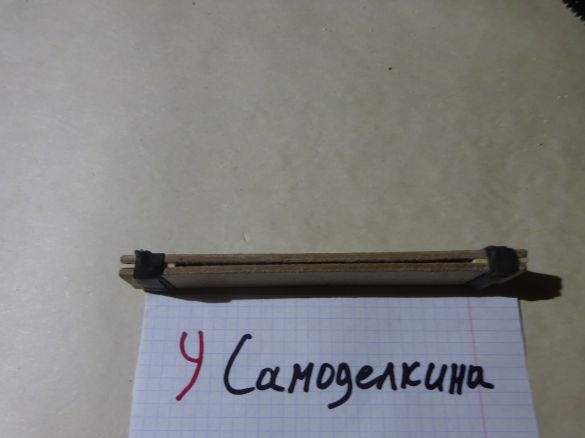

Step 6. We put two wooden gaskets on the edges of the first workpiece on a rough surface (so that the workpiece falls into a partially finished location). On top of them is the second workpiece with the smooth side facing out, so that future fasteners touch two rough sides. We take two rubber rings and wrap the “eight” ends of two hardboard plates. Our device is ready.

Step 7 (optional). We use the manufacture for the intended purpose: first we insert two self-tapping screws into it, then the device itself - in a vice, clamp. Then you can make any necessary action on the clamped product: everything is fixed, the thread is intact.

Conclusion

Yes, you can set a lot of screws here and at different heights. As you can see, the place with wooden inserts does not fall into the area clamped by a vice, which will not interfere with the mutual approach of the two plates and, therefore, a more reliable fit of fasteners. With frequent use, the device will lose its functions, therefore, plates from fiberboard, in this case, should be turned outward with their inner surface or replaced with others. Will any other material be suitable as the basis of the device except for wood-fiber board? Probably plywood (but it will be tougher), plastic or the same slats. Instead of rubber, you can use a rope, wire. Thinking, those who wish will find another use for this device.