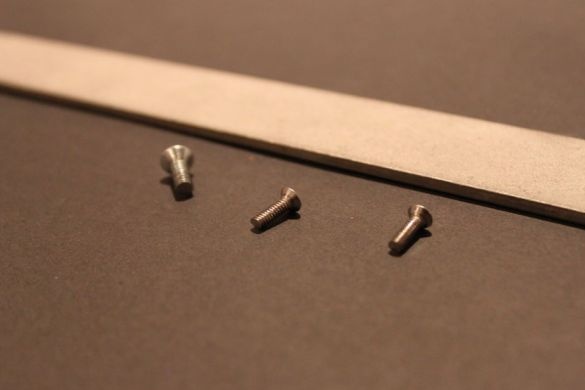

I propose to consider a reliable, durable, durable, simple stainless steel knife. This metal does not rust, which is very good for a knife, you do not need to follow the blade, handle and other components, the knife will always remain shiny. The author decided to make the design of the knife as simple as possible, which increases its reliability. Countersunk screws are used for assembly. This will allow in which case to disassemble the knife and repair, well, or clean.

In general, stainless steel is excellent for both making a blade and making a handle. This metal is quite durable, it can be hardened. But stainless steel is also of different grades. When hardening the blade, the metal changes color, which makes the blade pretty beautiful. Finding such steel should not be difficult for you. So, we will consider in more detail how to make such a knife.

List of materials and tools used by the author:

Material List:

- stainless steel plate;

- countersunk screws.

Tool List:

- tape cutting machine;

- a hacksaw for metal;

- files;

- scissors;

- paper;

- sandpaper of different grain size;

- ruler;

- tap for threading;

- screwdriver;

- screwdriver;

- drilling machine;

- lathe;

- disk grinder.

The process of making a knife:

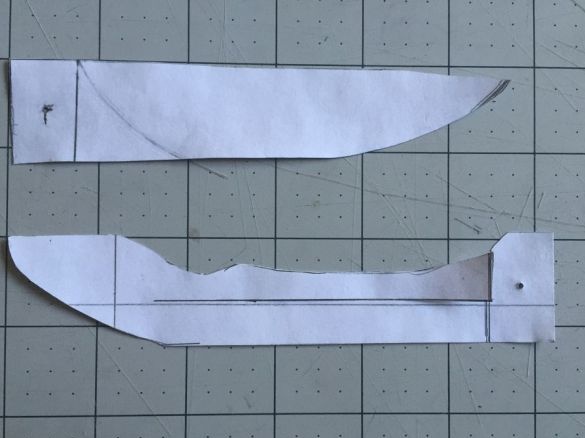

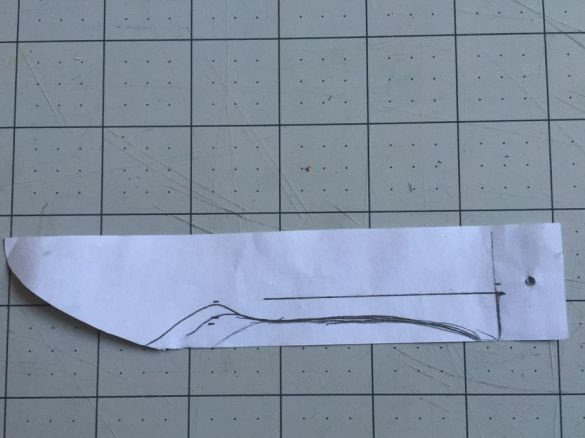

Step one. Design and cutout template

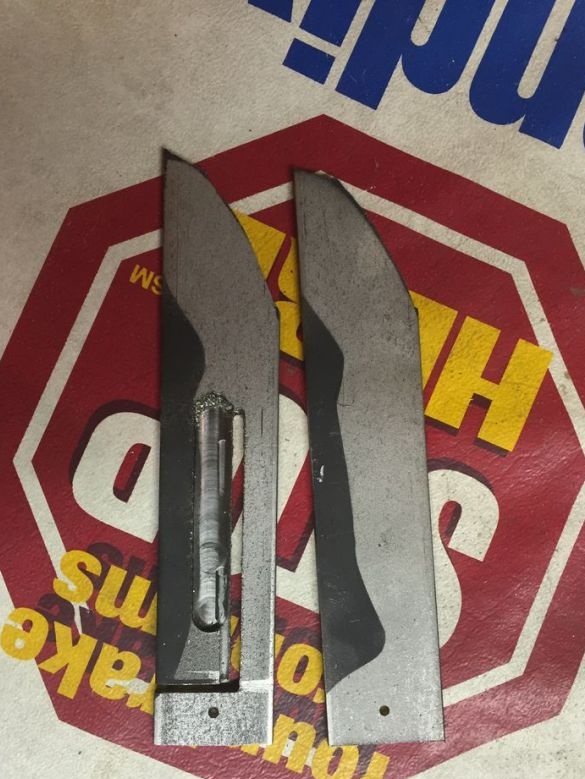

The first step is to design a knife on paper. Next, you will need to cut it, you should get two halves of the handle, as well as a blade. The locking mechanism on the knife is very simple, it is part of the handle. That is, this is a piece of stainless steel plate that springs. In the closed state, she draws in and holds the blade so that it does not fall out. And in the open state, an emphasis is created for the blade. To fold, you need to press your finger on this same plate. Also, a spacer is provided in the design to obtain the desired clearance between the halves of the handle.

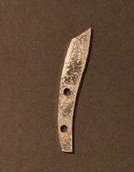

Step Two Cut the blanks

Now you need to transfer the templates to metal, there are many ways to do this. You can simply circle the templates with a marker. And you can stick them, but for this, use a good glue so that the template does not come off during the work. The tape cutting saw is best suited for such work, this will allow you to get almost perfect blanks. You can use a grinder, only after that there will be a lot of grinding work.

Step Three We drill holes and cut the threads

To assemble the knife, you will need to drill three holes, for this you will need a drilling machine and most likely, you will need drills with special tips. Stainless steel is quite durable and an ordinary drill usually does not take it. After drilling, make even small indentations for countersunk screw heads.

That's all, now you just have to thread the screws. Then a suitable size tap will come to your aid. With the help of two screws, the back is assembled, and with the help of another screw, the blade is attached. Once the holes are ready, you can already as an experiment.

And collect the knife and check if the locking mechanism works well.

Step Four Blade revision

We already have a blade, but we need to form bevels on it. There are a lot of ways to make them, the author decided to use a grinder with a grinding nozzle. We make the bevels at our discretion, with the author they merge with the blade, that is, the bevel smoothly passes over the entire width of the blade. The thinner the blade, the easier it will be sharpened and the sharper the knife will be.

After processing the grinder, there will be many deep scratches on the surface. They all need to be removed, for this we first use large sandpaper. Then slowly reduce the graininess, select the sandpaper all the smaller and smaller. As a result, you can use a polishing machine and make the blade mirrored.

Step Five Polishing

Handle the halves of the handles with emery paper; they can be made perfectly smooth or even mirror-like. We process not only from the outside, but also from the inside, so the knife will last longer. To make sandpaper work better, it can be moistened in water.

Step Six Blade hardening

Hardening is an integral procedure in the manufacture of a quality knife. Thanks to hardening, the blade gains high strength and does not stupid for a long time. For hardening, you will need oil or plain water. But it is better to temper in oil, since there is less chance that the blade is deformed or cracked. The author warms the blade with a gas burner, leading it along the blade for uniform heating. A blacksmith furnace is also suitable. We heat the steel to a bright red color, and then immerse it in oil or water. The quenching temperature for each steel is individual, never forget about it.

After hardening, the color of the blade will change, this patina looks pretty nice, so it makes sense to leave it. But if you wish, you can still polish the blade to a shine. In addition to hardening the blade, the author also tempered the locking mechanism so that it is stronger and springy.

After quenching, metal tempering is usually performed again so that it is not brittle and can spring. Generally speaking, steel is sent for an hour to a domestic oven, here the blade is heated at a temperature of 200-300 ° C, but it all depends on the particular grade of steel. And then the oven is turned off and allowed to cool with the blade in the closed state. On this vacation is over.

Seventh step. Finishing touches

All parts of the knife are ready, now you can assemble it! To do this, you just need to tighten the three screws. Sealant can be applied to the thread so that the screws do not unwind. That's all, the knife is ready to use! You just have to sharpen it to the state of the blade! Use grinding stones, special fixtures or ordinary fine sandpaper.

I hope you enjoyed the project, and you found something useful for yourself. Good luck and inspiration in the manufacture of your own projects. Do not forget to share your homemade with us!