In this project, we will look at how to make arrowheads from an old saw. The master, some time ago, was already making tips. He decided to make this game, taking into account past mistakes.

Tools and materials:

-Marker;

-Paper;

-Sheet of plastic;

-Knife;

-Saw;

-USHM;

-Metal brush;

- Clamps;

- Aerosol can with paint;

-Grinder;

-Tape grinding machine;

-Capacity with water;

-Dremel;

- brush;

-Wood dowel;

-Bandsaw machine;

- Paint tape;

-Glue;

-A thread;

-Protective glasses:

-Respirator;

-Gloves;

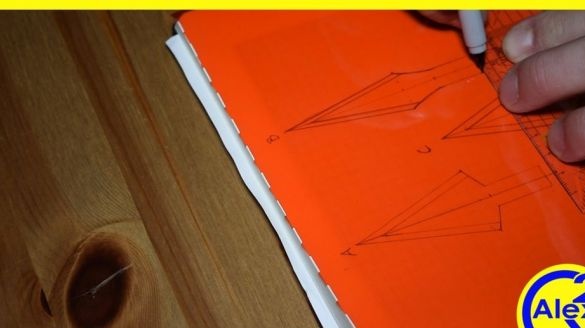

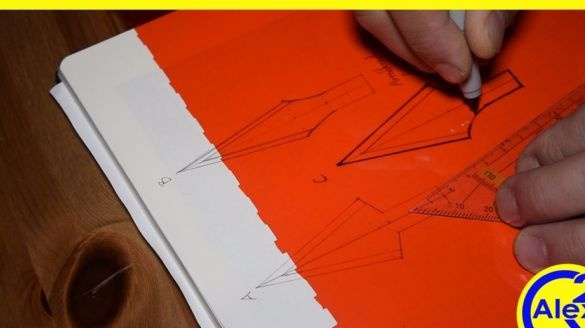

Step One: Stencil

On a sheet of plastic, the Master draws the arrowhead of the desired shape. Knife cuts out the stencil.

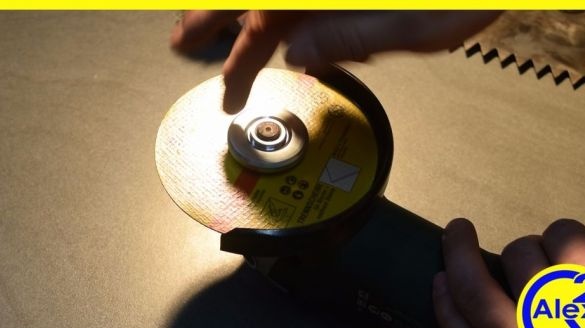

Step two: cleaning the canvas

With the help of angle grinders and brush nozzles cleans the surface of the hacksaw from rust.

Step Three: Making Billets

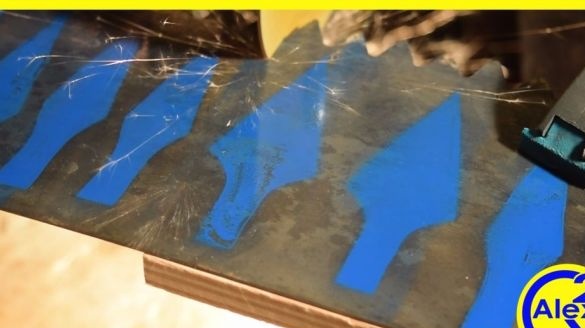

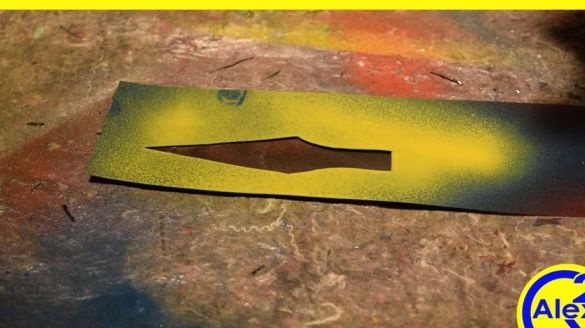

Transferring the stencil to the surface of the canvas.

USMMkoy cuts the workpiece.

When cutting blanks, the stencil, on some of them, deteriorated, and the master applied a new one.

Step Four: Cutting the Tips

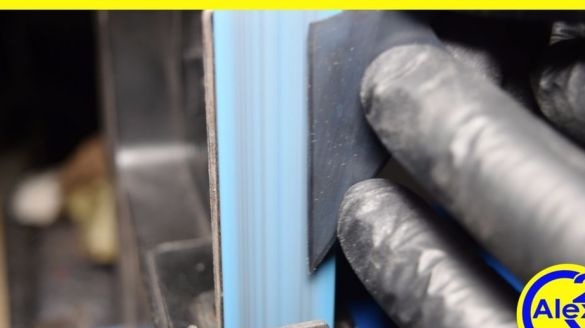

After all the blanks have been cut, the master proceeds to their processing. Clamps the tip in a clamp. Makes cross cuts. Cut off excess metal.

Processes the end face on a grinder.

Forms the neck of the tip.

Step Five: Grinding and Beveling

Grinds the surface.

Forms bevels of a tip. First, the master makes sharpening with a P-40 tape. To prevent overheating, periodically lower the tip into water.

Then it processes the blade with sandpaper P-120 and P-240.

Goes to the tape P-400.

Then flips the tip and processes the opposite surface.

Step Six: Blacken

With a brush, a special liquid for blackening metal is applied to the surface of the tip. The liquid enters into a chemical reaction with the metal, changes its color and protects the surface from rust. After a few minutes, wipe the tip. At the end, the master polishes the tip blade with P-2000 sandpaper.

Seventh step: attaching the tip to the pole

In a shaft of an arrow does a cut.

Grinds the tip of the pole.

Sets the tip. Tape over the surface of the blade with masking tape.

Applies glue into the cut, sets the tip.Wraps a thread around the junction. Coats it with glue. Clamps the edge of the shaft with a clamp. Leaves an arrow until glue dries.

All is ready.

A detailed video report on the manufacture of arrows can be seen below.