Greetings to fans of something to make. I bring to your attention such useful device like a brace. This is a knife for special woodwork. With it, you can conveniently grind, remove bark from wood and much more. As a rule, such a knife has two handles, so that you can comfortably hold it with two hands. You need to drag this knife on the material to yourself. This knife is an indispensable tool in the workshop and in the economy as a whole. For example, if you need to make a column for a fence, with the help of this knife you will quickly remove the bark from it. And if you bury the column with the bark, it will quickly decay or even begin to grow.

For the manufacture of a knife will need high-quality steel, which can be hardened. Otherwise, the knife will quickly blunt and this will cause it to stop cutting. The author used D2 steel to make the knife. In composition, this steel is similar to steel x12mf, however, it has less chromium. The carbon in this steel is more than 0.5%, which allows it to be hardened to moderate hardness. So, let’s take a closer look at how do it yourself make such a brace!

Materials and tools used by the author:

Material List:

- D2 steel or the like;

- wood for pens (can be machined from a log);

- epoxy adhesive.

Tool List:

- belt sander;

- forge furnace;

- drilling machine;

- vise;

- a lathe (to grind the handle).

The process of making a brace with your own hands:

Step one. Marking the blank

We take a piece of steel and do all the necessary calculations. You can see the profile of the knife in the photo. You can also choose the size at your discretion. All people have different power reserves, so the knife can be made specifically for you.

Step Two Cut a rough profile

When everything is marked, secure the workpiece securely and proceed with cutting. It’s best to handle this kind of work with a band saw. But if there is no such car, an ordinary Bulgarian will come to the rescue. To form rounded parts along the edges of the blade, the author used a drilling machine with a bat of suitable diameter. There is no need to rush in this business, work carefully, use safety glasses and gloves.

Step Three We form a blade profile

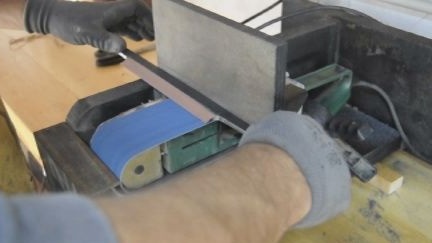

The blade profile is a very important knife parameter. The author has a bevel of 15 mm. This task can be best accomplished with a belt sander. The author began with a 36 grit sandpaper.Well, then we use a smaller sandpaper and bring the profile to the end. It is not necessary to sharpen the blade at this step, since the metal can easily overheat during hardening.

If there is no belt grinder, then you can make a bevel using files or a grinder.

Step Four Bend the handles

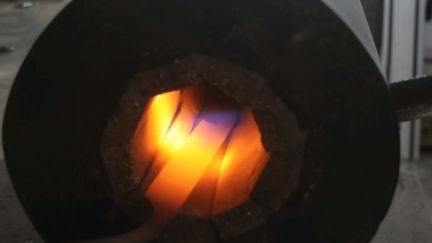

The edges of the tool need to be bent, these will be our handles. For these purposes, you will need a blacksmith furnace. We heat up the necessary parts red-hot, and then, when the metal becomes soft, bend the edges with a gentle movement. To do this, you can use a vice and a piece of pipe.

Step Five Steel hardening

Steel hardening consists of several stages, at least two of them are hardening and tempering. But the author also uses such a procedure as normalization of steel. Theoretically, this procedure is needed in order to relieve internal stresses in the metal. We heat the knife red hot, while it will have to lose its magnetic properties. If you bring the magnet to the knife, and it will not be attracted, we postpone the workpiece and allow it to cool in the open air.

Then you can temper, heat the metal in the same way, and then cool in oil. Oil can be used motor, vegetable and so on. But it’s best to use clean oil, as there have been cases when car mining spoiled metal. After hardening, you need to perform the last step - this is the release of metal. The essence of the procedure is to slightly warm the metal and allow it to cool smoothly, as a result, it will become a little softer. In this way, we ensure that steel is not brittle. The author heats his knife in the oven, taking into account the fact that for every millimeter of thickness 10 minutes should go, and the temperature is 200 ° C. Then simply turn off the oven and let it cool with the knife closed. That's all, now we have a perfectly hardened steel that can withstand heavy loads!

Step Six Make pens

For the manufacture of pens, the author used a piece of wood from an olive tree, as well as a lathe. We create the desired profile of the handles and drill holes. Steel handles will be put on the handles, which will restrain them from cracking, and thanks to which the handles will hold. At the end, be sure to soak the handles with oil to protect them from moisture and dirt. The author used vegetable oil, it is great for such things.

Seventh step. Final grinding

Now we go to the belt sander. Using 400 grit paper, we grind the knife. We remove scale and other defects after hardening. Gradually we reduce the sandpaper, in the end the author used belts with a grit of 3000, and then 8000 units. At the same step, the knife must be sharpened as high as possible. We use a tape machine with the smallest belt. We constantly wet the knife with water, so sharpening will be easier. That's all, now you just have to collect the knife.

Step Eight. Set the handles

To securely fix the handles, pour in the glue holes, PVA glue will do, and it is best to use epoxy. Now, with light strokes of the hammer, fill the handles. That's all, when the glue dries, the knife can be tested!

Step Ten Test

The knife passed the test perfectly and copes with its task. When storing a knife, do not forget to grease it with oil, as it can easily rust. On this project can be considered completed. Good luck and inspiration in the manufacture! I hope you have found useful information in this article. Do not forget to share your work with us!