At the end and during the working day, each conscientious craftsman begins to sweep rubbish in his workshop: from workbenches, tables and other planes. It is most convenient to do this with a brush. And nicer - with a homemade brush. A solid foundation for it can always be found, and which bristle to make is worth considering. But here some options loom. One of them is bristles made of plastic bottles: fortunately, a person has learned to cut strips of the required width from them. One author, experienced in the manufacture of original things, makes a hand-brush made of wood and used containers, consisting of polyethylene terephthalate. The manufacturing process is worth attention.

The author needed the following tools and materials:

Instruments:

1) hand saw;

2) an ax;

3) brace;

4) a semicircular chisel;

5) kolovorot (hand drill);

6) device for cutting strips of PET bottles;

7) a device for winding and straightening strips of plastic;

8) electric oven;

9) scissors;

10) bench vise.

Materials:

1) a piece of wood;

2) plastic bottles;

3) gum stationery;

4) chock platform (for working with an ax).

Manufacturing process:

Step 1. Primary wood processing.

The basis of the product will be wooden material. We take a small chock and chop it in half with an ax.

Step 2. Work with a braid.

We cut off the excess parts of the die with a braid so that as a result, on one side of it

the handle of the upcoming brush turned out.

Step 3. Processing the sides.

With a semicircular chisel, we make three shallow recesses on each side (as well as the back) side of the working part of the workpiece base for more reliable fixing of future plastic strips. But the bark is not completely removed - to give a natural look to the material from which the brush is made.

Step 4. Cutting out the grooves.

Using a hacksaw, we make six cuts across the handle with a depth and width that are sufficient for placement in the grooves of the beams, which we will further make from cut strips.

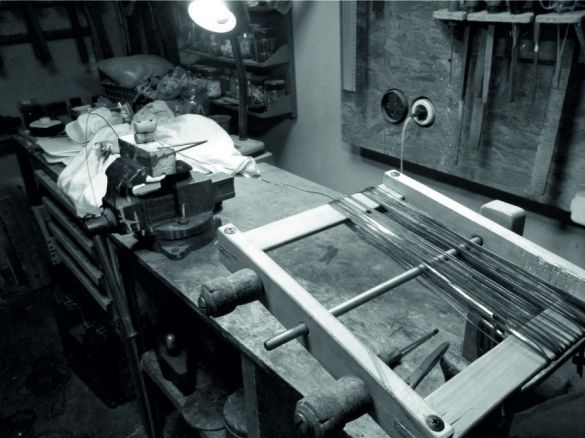

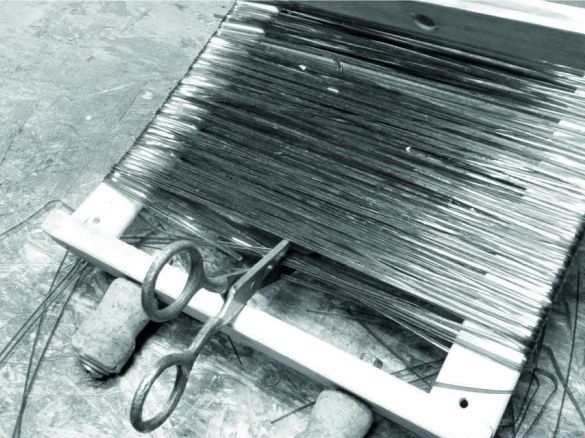

Step 5. Making strips of plastic bottles.

Now it's time to cut the stripes.This will require special devices made by the author earlier: for cutting, straightening, winding - strips. You will also need an electric oven to stiffen and shape the strips. Below are the photographs taken during the previous production by the author of his first sweeping brush with a design different from the design offered in this workshop. After cutting, winding and drying, it is necessary to cut the strips with scissors. For convenience, with further use of the strips, it is recommended to tie them temporarily with stationery or other elastic bands.

Step 6. Attach the strips to the tree.

Having picked up a bundle or bundles of finished strips, insert them into the grooves. Evenly distributing the strips along the entire base of the groove, we tie them with a longer strip. Having done this operation several times when moving from the end of the workpiece to the handle, we bind it in two turns around the last. A substantial part of the work has been completed.

Step 7. Align the ends of the strips.

Next, the master grabs the bristles of the brush with his hand and chopped off the protruding ends of the strips with an ax, thus bringing everything to the same length.

Step 8. Drilling the handle.

For more rational storage of the brush, it is worth drilling a hole in the handle. In this case, with a scoop.

Step 9 (final). Shrink bands.

In order for the strips of plastic to hold tighter and more securely in the grooves, you need to pull them together very tightly, squeeze them. With the help of hands you can achieve a certain result, but still the heat from the electric oven will make it better. Therefore, we put the brush with the surface opposite the working one on the metal grate, and the grate on the vertical racks of the electric furnace, thereby allowing the tightening strips to dry out. The result was a brush-brush as it was intended by the author.

Conclusion

After manufacture, the brush turned out to be quite decent (although it looks like it was made in haste), but there is a risk of touching the strips that tighten the bristles with a sharp object and damage the product. Suitable for sweeping both wood and other waste material. It is also possible to clean, due to the stiffness of the bristles, hard and cloth surfaces.