Does anyone need to talk about the paramount importance of providing water to the subsidiary farm? I think no. So we, as a good example, in the very first hours of our stay, were faced with necessity and desirability. It is good that not far from our site is a public village spring with good water, which people take for drinking. But close, in our case, does not mean easily - it was necessary to carry or carry water to the mountain. But where to go - wash and wash your hands no matter how cool you need. Concrete work, again - there are all sorts of foundations ... As I recall, I will tremble. Nevertheless, he drove as cute.

A neighbor discovered our spring on our site, as he threw it on the go, as if, out of the corner, you have mint overgrown, dig around, maybe something will flow. Rummaged and really flowed. There was a super task, to collect this water and deliver it upstairs for use.

What was used in the work.

Instruments.

Standard trench and marking tool for earthworks. A spade was very useful, somewhat more powerful than conventional bayonet. Cutting machine for cutting reinforcement. Sledgehammer, scrap, without them anywhere. A concrete mixer and associated ones were also used - a trough, buckets. Trowel of course. A set of simple carpentry tools.

Materials

Fittings in proper quantity, knitting wire. Of course, the components for the preparation of concrete. Boards for formwork, fasteners.

Initially, the place where tiny streams made their way was excavated somewhat and a container from a piece of a ceramic pipe for land reclamation was dug below it. The pipe - they gave it to the broken one, they managed to “grinder” with a diamond disk, to cut out of it a cylindrical piece about 60 cm long.

Water collected in a tin chute a meter and a half long and fell into a dug piece of pipe, a sort of well, from which it could be pumped up to the household. Excess water through a special "nose" was diverted below. Subsequently, the tin chute was replaced by a plastic sewer pipe, which reduced the entry of debris into the water. The arrangement of the spring was not completely perfect - the water intake pit was heavily overgrown with grass, mint, which, having died, got inside.The walls of the pit often collapsed, the "well" for collecting water did not have a bottom - it turned out that the soil was very sandy and strongly let water through - even though the pump was running for a long time, there wasn’t enough incoming water, it exposed it, which represented a risk of it coming out system. The hose ran along the surface, which did not allow the use of a spring in winter.

The first improvement was the organization of a waterproof bottom in the "well". To do this, I had to dig out a ceramic glass and cast a concrete bottom. After the concrete had completely hardened and the initial strength set, the glass was returned to its place. The result was a much larger amount of water that could be taken by the pump - in practice, at that time a low debit, the pump performance was not enough (vibration “Aquarius”, a significant height difference) in order to pump out all the incoming water. It was possible to leave a working pump for a long time, which solved the problem of watering in the warm season.

A much more serious revision of the spring was undertaken a few years later - a water intake “capturing” chamber was made and the water supply hose was replaced with a plastic water pipe placed in the ground to a considerable depth. The volume of work is significant, it was hard and to the ears in the mud, however, the result made it possible to comfortably use spring water all winter, our own bathhouse was involved.

So.

A concrete fence was cast over the pit, where streams of water made their way to the surface of the ground. For this, marking was carried out on the ground, with the help of pegs and ropes he organized a certain working space for casting. The cleared place had a quadrangular shape and a more or less flat bottom. Where it was impossible to arrange the bottom on the ground, thick boards with supports were used. On a cleared place, a quadrangular formwork was erected, tending to a square in shape. The formwork was made of wooden plank boards and strengthened in place with pegs, ties and struts. The inner surface of the formwork was lined with thick plastic wrap. The edges of the film are fixed with a construction stapler. Reinforcement was in two levels, two reinforcing bars in length. Periodically, long reinforcing bars were linked together in short pieces. In the corner most lowered on the terrain, a piece of a sewer pipe with a diameter of 50 mm was sealed.

After all the preparatory work, I started concreting - on the edge of the slope, where you could still drive up with a construction car (to deliver water, materials), a concrete mixer, containers for dumping the finished concrete mixture were placed. Down, had to wear buckets. The components were mixed, the finished solution was transferred to the formwork and fit tightly, with the removal of air bubbles. Let me remind you - the ready-mixed concrete mixture should not be liquid - it should be laid exactly, otherwise the separation into components and the strength of the casting should not be avoided.

After several weeks of regular watering of the casting, she gained some strength. The wooden formwork was dismantled, the boards replacing the bottom in some places were removed.

The next step was the descent of the fence to the duty station. He acted in the traditional way for digging wells - he dug from the inside under the bottom of a heavy fence. After opening the corresponding free space, the mold gradually sank into place under its own weight. Contrary to fears, nothing burst, did not break. The truth has accumulated, to the full - wet heavy clay sticking to a shovel, but managed nothing.

The fence did not immediately fall into place, completely blocking the water drain, and had to tinker to completely neutralize the leakage of water, hammer the front edge of the fence outside with thick clay. It can be seen that the flow from the pipe has become much more powerful - the area from which water is collected from the piercing streams has increased significantly.

For normal water supply to the bathhouse and the house in the winter, the water supply from the irrigation hose was replaced with a plastic pipe.The pipe was insulated with a roll insulation and, together with the cables (one worker, the second spare), was buried in the ground. The depth of the trench was slightly less than one and a half meters recommended for our area in the construction literature for guaranteed immersion below the freezing depth, however, given the additional warming and the presence of snow cover over the water supply, this decrease is quite reasonable. Moreover, the mode of operation of the water supply system was supposed to be periodic — after the tank has been set up in the room, the water is drained into the “well” at a slope, but it is not in the pipe.

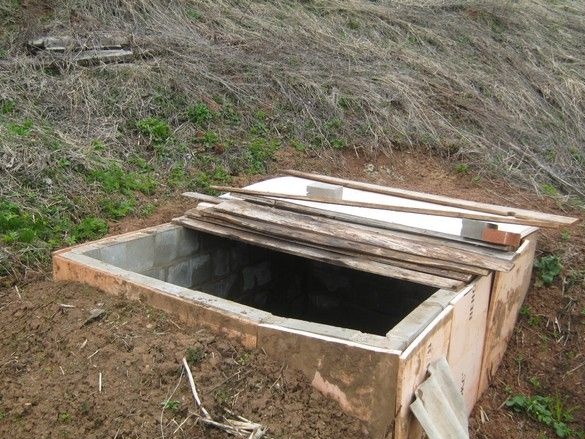

The concrete “sandbox” was laid with boards, for the winter it was additionally insulated with sheets of “Penoplex”. In winter, the water supply system worked flawlessly, and we were blissful - at least pour water, at least wash ourselves in the bathhouse. Despite the severe frosts of that “control” winter, nothing froze, there was more than enough water. Periodic inspections showed that the fontanel’s debit in frosts does not decrease at all, on the contrary, there is more and more water - apparently the water washed itself additional outlets to the surface.

Spring revision showed that for all the health of the system, some more cosmetic improvements are required to increase the usability. For example, due to the small height of the concrete fence (the capture chamber) dug into the slope, the not strengthened slopes are gradually eroded by rains and melt water, fall onto the chamber cover, melt water in the spring or rain during heavy rains may fall into the spring, which is not desirable . It was decided to increase the height of the capture chamber, slightly above the ground level at the highest point. The walls, for durability and relative lightness, were laid out of ready-made concrete blocks for internal partitions, hollow inside. Block thickness 90mm.

The collapsed clay is cleared with some reserve, waterproofing is put on the upper edge of the concrete collection chamber. After descending to the place of work of all the materials, he prepared a cement-based masonry mortar, dressed up in boots with two woolen socks (cold water), and set to work. So that the raised clay suspension doesn’t fall into the accumulation “well” with a deaf bottom, from which it is inconvenient to scoop up dirt, I made a sort of shunt during my raging in the collection chamber - I conducted a stream of dirty water past the storage tank, draining it to the ground lower down the slope. I laid out the walls of the capture chamber, a little higher than the level of the surrounding soil, it turned out not too high - it’s not difficult to get inside without stairs and steps, for example for cleaning. As a matter of fact, to reach the drain hole by hand (to clean it) it is enough to be overweight. The walls from the outside were insulated by Penoplex 20 mm thick and littered with soil (clay). From above, the capturing chamber was closed by a cover from boards.

Wintering showed the efficiency and reliability of the solution - the soil does not fall off, rain and melt water (except from melting snow marked on the cover) do not get inside.

The last revision is ahead - the construction of a storage tank of a small decorative house over the "well" and the final embankment of the structures.