For the manufacture of wheel chocks folding need

1. Two pieces of metal 200x100x4

2. Two pieces of metal 170x100x4

3. Two pieces of metal 100x100x4

4. Two corners on 25 long 100

5. Four one-piece joints

6. angle grinder (grinder)

7. Welding machine

We saw off 10mm from a corner from one shelf. We retreat on a wide shelf 4mm from the inner corner and weld a long part (200)

Next, we weld two hinges to the middle part (note the hinges are boiled in different directions)

Next, we weld a short part to the right hinge (the hinge is broken)

Well, to the left a long detail.

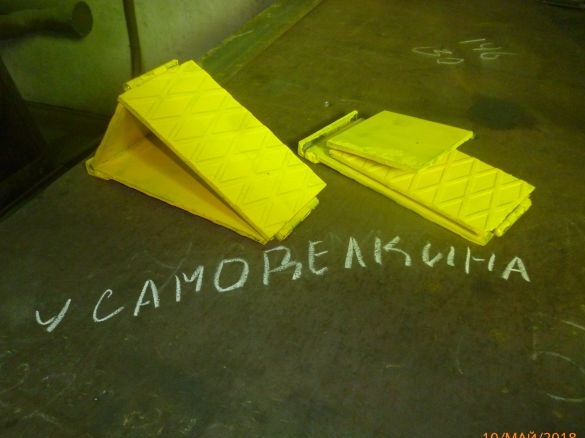

That's what it should be

We do the second in the same way.

That's what they look like when folded.

It remains to paint and stitch the cover.