Hello to all lovers homemade. In this article I will tell you how to make a stand for checking spark plugs do it yourself. This stand will help determine the condition of the candle, as well as look at its work under pressure. It will be useful to those who independently service their car, and also engaged in minor repairs.

Before reading the article, I suggest watching a video with a detailed process of assembling the stand for testing spark plugs, as well as testing it in real conditions.

In order to make a stand for checking spark plugs with your own hands, you will need:

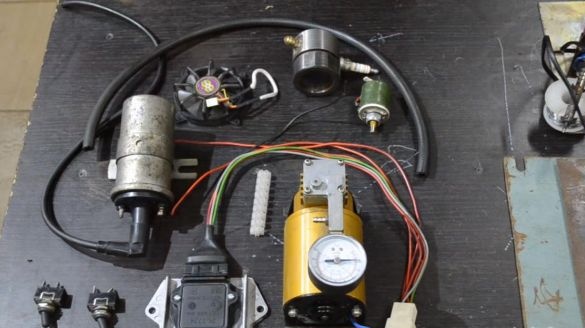

* 12V portable car compressor

* Switch wiring from the car "Lada"

* Ignition coil with armored wire

* Two toggle switches

* Three-pin computer fan

* Variable resistor

* Soldering iron, flux, solder

* Small length of hose

* High pressure chamber with thread under the spark plug

* Sheet metal 2 mm thick

* Welding machine

* Spray paint

* Welding mask, gaiters

* Safety glasses, earphones, gloves

* Angle grinder, cutting wheel

* Electric drill

Step one.

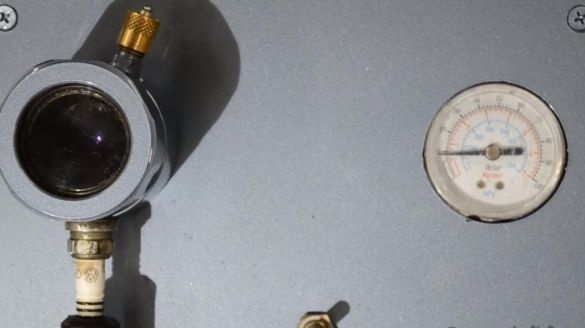

The main detail of the stand is a high pressure chamber.

It was ordered from a turner, but if you want, you can do it yourself if you have a metal lathe. This camera is made of a round metal blank, a hole is made in it and a mirror is inserted at an angle of 45 degrees, a thread is cut on the body and on the cover.

Plexiglas with a thickness of about 4 mm is installed in the lid, for a snug fit there is a rubber ring inside the lid, and a ring of a larger diameter is planted on the case itself, which ensures the greatest sealing.

A hole was drilled on the case itself and a thread was cut for the spark plug, and a drain valve is welded to this hole by 180 degrees, the role of which is a nipple, it is designed to release pressure in the chamber before unscrewing the spark plug.

Also on the case itself is a fitting for connecting the hose to the compressor, on the same side two holes are drilled and a thread is cut for installation on a stand.

Step Two

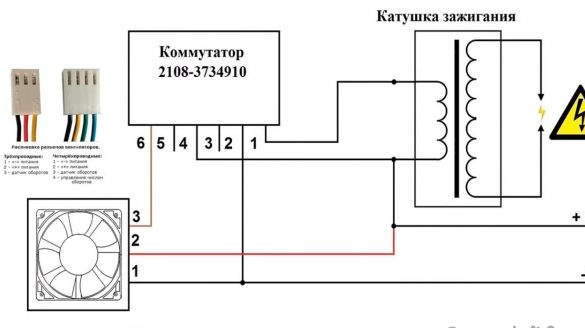

Next, we collect the electrical part.

We connect parts according to the circuit, after which we check the circuit in operation by connecting a 12 volt power supply.

When the power is connected, the fan starts to spin and the ignition coil generates a spark, and with the help of a variable resistor, the beat frequency of the spark can be changed, that is, simulate engine speed.

After checking, we solder the wires securely with a soldering iron and solder, for better soldering we use flux, then we isolate the bare wires.

Step Three

We cut parts of the case from a sheet 2 mm thick with an angle grinder, there are no special requirements, the main thing is that all the parts of the stand fit inside the case. When working with an angle grinder, be careful to wear safety glasses, gloves and headphones. Then, using a welding machine, we weld the case from sheets of metal. When working with the welding machine, do not forget to use a welding mask and gaiters.

Next, we install all the parts inside the case, screw the ignition coil to the bottom, and switch to the wall of the switch, also screw the compressor.

To remove air in the side wall, drill holes in a circle and install a fan.

To control the speed at the top cover, we screw a variable resistor into the pre-drilled holes, as well as two toggle switches, one for turning on the compressor, the other for turning on the ignition coil and fan. We also fasten the high-pressure chamber to the top cover with two bolts, connect the hose from the compressor to its fitting. From the case we bring out wires for connecting power and an armored wire with a candlestick.

Step Four

The final step is to paint the finished stand with a spray can of paint.

After drying, you can proceed to testing the spark plugs.

First, manually screw the candle into the high-pressure chamber, then tighten it carefully with a wrench.

We turn on the toggle switch, which is responsible for the ignition coil and fan, in the window you can see how the spark breaks out, if there are no breakdowns in the body, we increase the pressure in the chamber.

We turn on the compressor start toggle switch and we see that the spark has increased, approximately in such conditions the candle works in the engine.

If there is a breakdown of the spark over the body, then the candle can be considered unusable.

That's all for me, thank you all for your attention and creative success.