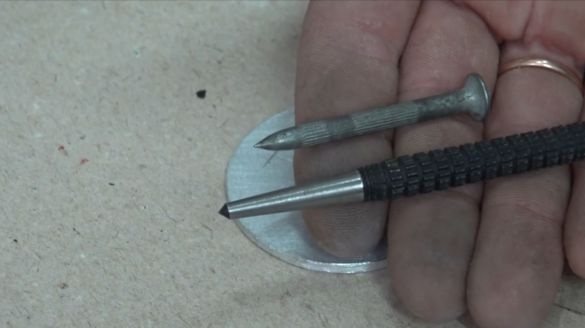

We all periodically have to drill holes in the metal, and in order to do this evenly and correctly, we need to make markings, and then screw them up. The key to success is proper punching. Someone uses a standard factory core, someone uses an ordinary wall plug, both methods are good, but they do not always give the perfect result.

Most often, punching does not cause any trouble, and the notch is obtained exactly in the center, because its center is very sharp. But sometimes it happens that we miss the core, we hit it not quite straightforward, and when the core goes deep, it goes a little to the side, and in this case we definitely can’t drill a hole anymore.

More often than not, in order to correct the notch, we slightly shift the core and strike again.

The core slides along the side wall of the first cone, pulls the material a little and seems to be in the center. It would seem that we have found the exact center, you can drill and get the exact hole. But this does not actually happen. But this does not happen because around the punching we have a small rim, and its height along the perimeter is not the same.

In the place where punching was done correctly at one time, we got a hole exactly in the center. And here, where we made a little mistake and corrected, anyway the hole turns out with an offset.

Of course, you can train the eye and coordination of movement, but anyway, errors will periodically arise, and today we will do what we will do a spring core, which eliminates errors.

We need a steel or bronze bar, and we need a spring with this appearance:

It is advisable to take a spring longer and softer. And we will use the same dowel as a bike.

We will be engaged in turning works, but we will not use a lathe. We will use an ordinary drill. For a drill, we need here such a rack, which can be successfully replaced with a conventional wooden block.

To grind the bar and give it the desired shape, you can use any drill, the author will use the "Champion m3 marathon" with a 37th tip.

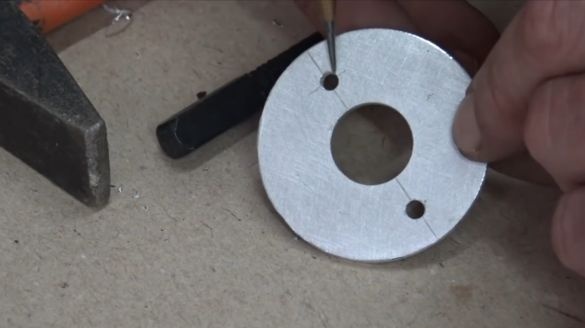

The dowel has a diameter of 4.5 mm, but due to the notch, the diameter of its body is slightly larger. To begin with, we will cut out the workpiece, drill exactly in the center a hole with a diameter of 4.5 mm, into which we will hammer the trimmed tip of the dowel.

The process is extremely simple. The workpiece rotates with a drill, and the disk acts as a cutter.In the same way, using a spherical bur, we find the center.

Although our workpiece is not centralized, we still found the center very accurately. In order to get an accurate coaxial hole, a drill with a diameter of 4.5 mm must be clamped in a vice. Then just rotate the workpiece and push the workpiece onto the drill.

Preparatory work is done and it is possible to form the outer contours.

If your drill is not perfect and there is play, then you can use, for example, a wooden cone as a tailstock. You need to start work with light touches until you get an even symmetrical shape. If you have large carbide burrs, you can use them, they give a significantly larger removal.

The tip can be made of any shape, the main thing is that there is a belt. Behind the belt there must be a step and then a brush follows.

The brush diameter is 1 mm larger than the inside diameter of the spring.

We cut off the excess from the spring.

Hammer the tip.

In order not to immediately spoil the tip, we will do this on a copper anvil.

On the reverse side, the master made a gentle cone so that the spring is better put on.

To put on a spring, it must be rotated so that the coils open and expand. In order to remove the tip, rotate the spring in the same direction and tighten.

And now, in the same way we grind the shank.

Here is the core and ready.

How does he work? And it works very simply. We install it in the right place, pull the spring and release it.

The spring is certainly small, so the depth is not so great, but it is quite enough to drill. Also, the impact can be enhanced by increasing the weight of the shank.

To get deeper marks, just hit a few times.

So our core is ready, simple and convenient, and very reliable. And most importantly, a hammer is not required to work with it. Another plus of this core is that it completely eliminates errors with an incorrect, with an uneven hammer blow. It acts approximately like a Japanese saw, which we pull on ourselves, and it straightens. And in this case, when we stretch the core, the spring straightens in one line, and when we release the back, the spring also compresses strictly in a straight line, and the impact falls exactly in the center without any displacements. This idea, of course, is not new, but I hope that it will be useful to someone.

On this our master class is over. Thank you for attention. See you soon!

Video: