Hello to all lovers homemade. In this article I will tell you how to make a foam cutter do it yourself. With its help, it is possible to cut polystyrene foam of various shapes, necessary for different purposes, for example, aircraft modeling. This homemade product is quite easy to manufacture, so that everyone needs the materials necessary for assembly.

Before you read the article, I suggest watching a video with a detailed process for assembling a polystyrene cutter, as well as testing it.

In order to make a foam cutter with your own hands, you will need:

* Building corner

* Two wooden bars

* Self-tapping screws

* Screwdriver

* Nichrome thread

* Waste stool or plywood sheet

* PC power supply

* Metal corner

* Copper pipe

* A piece of polystyrene for inspection

Step one.

First you need to make a stand for the cutter, for this you can use an unnecessary stool or, if desired, make boxes of plywood sheet. Since an unnecessary stool was idle, it was decided to make a base out of it, we make a hole for it in a copper tube using a screwdriver and a drill on wood. You can get a copper tube from the condenser of an old and unnecessary refrigerator, usually a tube of suitable diameter is used there, in this homemade product it is needed so that the nichrome thread does not burn the tree.

Step Two

Next, we screw the wooden block to the end of the stool with the help of screws and a screwdriver, while maintaining the perpendicularity of the building corner, so that in the end the cut on this cutter is as even as possible.

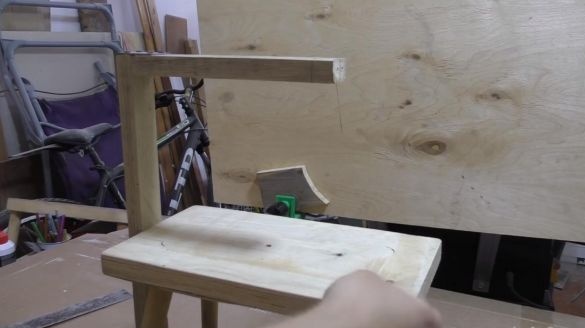

Then, with the help of a metal corner, we fasten another bar at a 90-degree angle to the wooden block, in the end it should turn out something like this.

Step Three

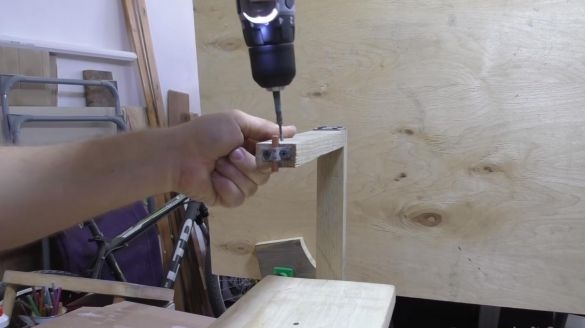

Having sawed off the necessary length of the copper tube with a hacksaw for metal, we press it with a metal plate to the bar, screwing in two screws, while also maintaining perpendicularity.

To fix the nichrome thread, we screw a self-tapping screw into the upper block using a screwdriver.

After that we take a nichrome thread and thread it into copper tubes above and below, then we wind it on the lower screw near the tube, then on the upper one, making a slight stretch.

Now we connect the power supply from the computer, for it to work without a PC, you need to close the green and black wires between each other.

We wind the wires from the block to the screws and turn on the power.

After the first inclusion, the nichrome thread is slightly stretched, so we pull it again and you can check the cutter in action.

Step Four

Check the finished cutter on the foam. We turn on the power supply and move the foam in the right direction, a nichrome thread cuts it through and as a result we get a segment of the necessary shape. When working with this torch, you must observe safety measures and in no case do not touch the nichrome thread with your hands.

Using this cutter, you can make aircraft models, boats, and much more, where foam is used.

That's all for me, thank you all for your attention and creative success.