In the article "Knife in the style of Nepalese kukri" The master for the knife handle used mosaic pins made do it yourself.

As you can see, on the knife handle they look good. Now let's see what will be needed for their manufacture

Tools and materials:

- Brass tube 10 mm;

- A pipe from stainless steel 10 mm thick;

- Copper tube with a diameter of 8 mm;

- 6mm brass tube;

- Aluminum wire 3 mm thick;

- Metal rod 1.2 mm;

- Two-component epoxy resin;

- Color pigment;

- Board;

-Pipe cutter;

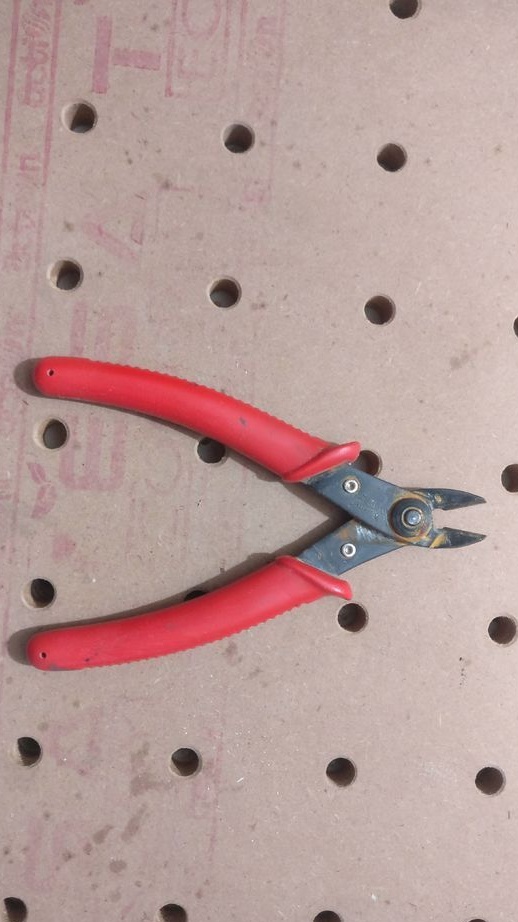

- Nippers;

- Hacksaw for metal;

- hair dryer;

- drill;

- A syringe;

- Files;

- Sandpaper;

- Super glue;

- Masking tape;

Step One: Material Preparation

At the first step, the master cuts off tubes of about 10 cm. Then he cuts off metal rods and aluminum wire. Part of the aluminum wire master weaves. Folds three pieces together and wraps one end with masking tape. Then clamps the end in a vice, and the second end in the chuck of a screwdriver. Turns on the screwdriver at low speed and weaves the wire.

Step Two: Build

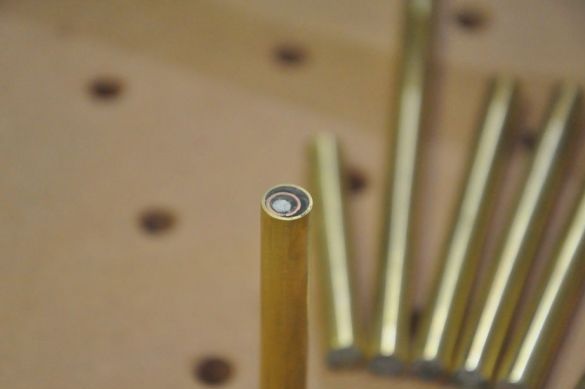

Then the master begins to collect the mosaic. Inserts one into another, inserts wire rods. It composes the material to your liking. For fixing uses superglue.

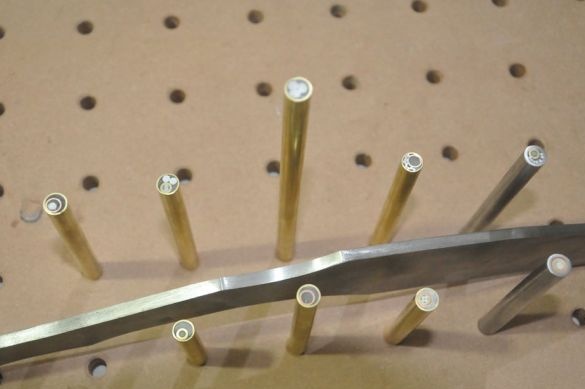

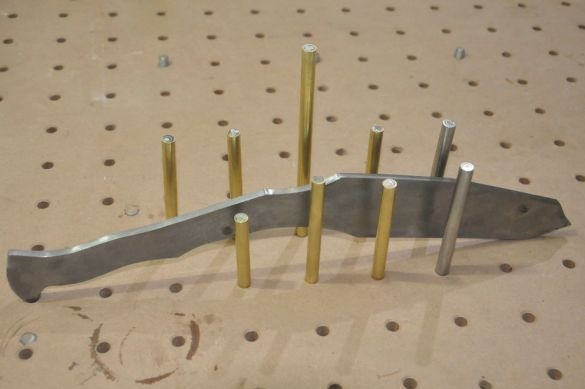

Step Three: Stand

Next, you need to install the tubes in an upright position. A master drills a series of holes in a board. Installs tubes in the holes.

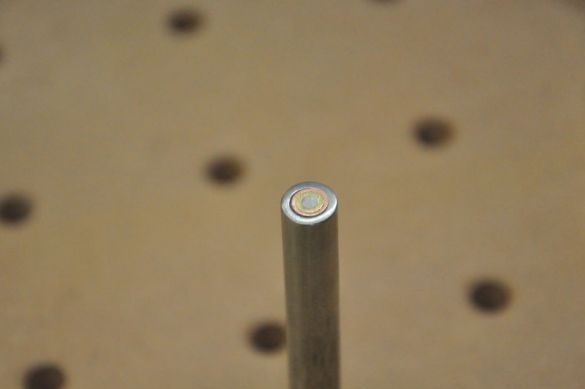

Step Four: Fill

Knead epoxy. Adds pigment. Using a syringe, pour epoxy into the tubes. Heats the tube with a hairdryer to remove air bubbles from the resin.

Step Five: Grinding

After the resin hardens, the master removes the pins from the stand, and then processes their ends with a file and sandpaper.

The pins are ready.

The whole process of making pins can be seen in the video.