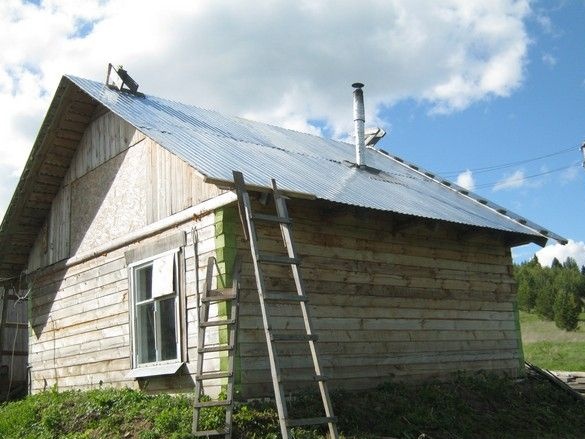

It's about the roof of my workshop. The room, of course, is important, but possessing a kind of "industrial" design - severely, reliably, but without special frills. The roof and roof are therefore appropriate.

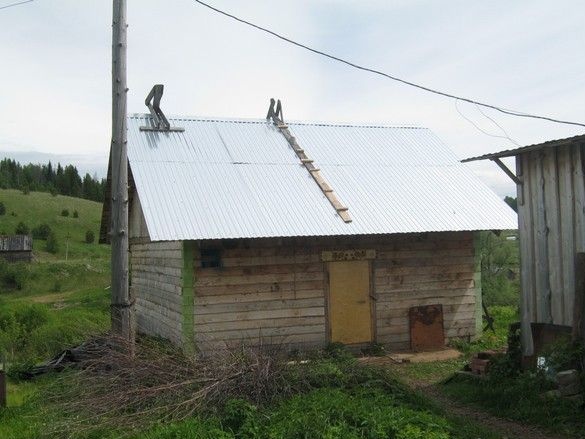

The history of this roof is stepped - initially, when the workshop was being built, all available means were used to purchase timber and boards, the roof was used to save, it was decided to make a temporary one - to winter, and in the spring, replace it with a permanent one, more thoroughly. The roof was made of one layer of roofing material, the sheets of which were fixed with wooden slats. It is appropriate to recall the maxim that there is nothing more permanent than temporary, and about the “promised” and “three years” - the roof with such a roof stood for exactly three years.

This spring turned out to be very cold and windy, very often hurricanes up to 22 m / s occurred, and we located on a sort of elevation, on the very windmill, got a fair portion. Mine, holding on to the roof with my last strength, ruberoid pulled apart - many small holes formed around the nails and at the end of the story, another flurry tore two pieces of the roof. Prior to this, several times had to climb patch holes, the same roofing material and slats.

Ahead, in the winter, the right amount of profiled galvanized steel roofing sheets were purchased in the city, and they were waiting in the wings, in the same place, with relatives. It was planned to bring and use them in the spring - when the snow comes down and the road dries - to us, in the village, it leads with a hefty climb, which can be walked only in the dry state. There is already a joke about the “northern delivery”, only for navigation. However, I had to, without waiting for the road to carry the roof, and to drag it on the mountain yourself. But nothing done.

A few words about choosing a roof. As a matter of fact, the main priority was the cost, but also a few aspects that had to be kept in mind, the main one of which was the possibility of relatively simple installation with one pair of hands - it so happened that from close-living relatives, mostly ladies. In general, work of this kind, if possible, is done thoughtfully and independently - hired comrades are either unjustifiably expensive, or crooked and drunk, and letting them, no matter how significant a height, is simply dangerous.

The roof is made of corrugated asbestos-cement sheets - very heavy sheets, if properly drilled with preliminary holes and without over-tightening the screws, work for a long time and burst nothing. The roof is heavy - wind resistance, after some time, the sheets darken and grow with all primitive vegetation, and it looks like this, moving his fingers in the air - picturesque. The most inexpensive roof option. In a word, everyone is happy, but the sheets that we have for sale are quite large, it is difficult and dangerous to mess with them alone.

The next in cost is the metal analogue of “slate” - profiled sheets of galvanized steel. There is no question of any decorativeness here - a shiny roof is certainly not the most amazing sight, in addition, light sheets practically do not load the roof - they do not make a feasible contribution to the wind resistance of the structure, traitors, however, are inexpensive, require simple and not laborious installation . Light sheets, easy to turn independently, including at height.

More prettier, colored - painted sheets of profiled steel, much more expensive than just galvanized ones, heat up much more in the sun and require very careful installation and handling, therefore they were rejected.

So, it is customary to use profiled galvanized steel sheets as roofing material. Unpainted. To save money, I decided to omit all sorts of additional bent elements, there was only a skate left, of course, I could not do without it. The horse decided to bend from the sheet on its own - practice shows that bent elements are usually unreasonably expensive, especially since the operation is simple.

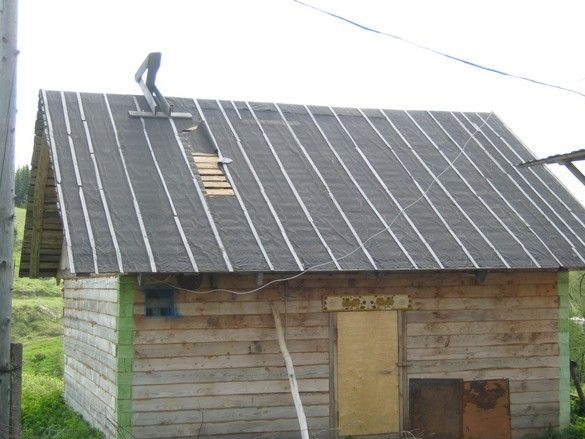

A common practice is to put a special membrane under the “corrugated board” that protects the wooden part of the roof from drops of condensed moisture. It is strongly recommended by all sorts of "consultants" in specialized stores. In principle, it would be possible to apply it - just in case of fire, but climbing during installation on a rather steep roof with an attached membrane is not particularly convenient, moreover, roofing works were carried out almost in emergency mode - daily rains left little time for work, they could start in any time and completely “open” the roof, at least on one side, it was dangerous. We had to work as follows - a small part of the damaged roofing material with wooden slats and nails was removed, the bare part was immediately covered with sheets of a new roof. It would be difficult to use a membrane in such an installation.

The study of SNiP II-26-2010, SP (Code of Rules) dated December 27, 2010 No. 17.13330.2011- “Roofs” showed that a moisture-proof membrane under the roof made of profiled galvanized steel sheet is enclosed in the case of an attic living room and when using insulation or continuous boardwalk under the roof (lack of ventilation). In other cases, the usual ventilation openings in the attic are enough. The logic is quite captured - increased humidity and / or difficult ventilation in the attic, cause the appearance of drops of condensate from the inside of the metal roof - it is necessary to protect from them (water drops) wooden structures with insulation if there is one. Since all conditions (ventilation, lack of a dwelling - steam source, crate at intervals) were fulfilled, the membrane was also omitted.

So, I started installation.

What was required for this.

Instruments.

A screwdriver, this is without a doubt, without it anywhere, plus a special nozzle with a magnet for hexagonal screws. Hammer, pincers for pulling nails, possibly a larger nail clipper. Roulette, scissors for metal, cutting machine - "Bulgarian". Strong stairs of the required length and specialization (roof). A pair of clamps for arching the ridge.

Materials

In addition to the proper amount of roofing sheets themselves, we needed a sheet with a tail made of even galvanized steel and three boards slightly more authentic than the sheet for making the ridge. Special roofing screws, a few scraps of boards and a bar for the organization of the "template". A few ordinary screws.

Sad a

Preliminarily freed up space on both sides of the roof slopes, mowed tall grass. For ease of installation, I made a sort of permutable template - from the inside of the roof overhang, screwed two trim boards, measuring them to the desired distance from the bottom board of the crate, screwed on the block on which the bottom sheet of the roof rested. The bottom board of the crate was quite carefully aligned with the "log house" wall, so it could well be used as a "base". The length of the "template" was enough for two rows of sheets, then rearrange. Overhang of the edges of the sheets for the laths of the crate - 50mm. It is quite convenient - it looks aesthetically pleasing, streams of water do not fall on the boards and roof beams even with significant winds, the edge of the metal sheet turns out to be quite rigid - it is not damaged when using the stairs.

When dismantling the old ruberoid coating, I paid close attention to collecting old nails and pieces of wood with them. At each descent from the stairs, he collected and stacked all the nail rods near the wall. He carefully collected the nails pulled out on the roof into a pocket. Ruberoid pulled to the non-working side, behind the workshop. Thus, nothing was lying underfoot, and one could walk without fear.

The sheets are fixed with special self-tapping screws with an ersatz-drill on the tip, a hexagonal head and a large washer equipped with an elastic band. Achtung! These screws are screwed into the "bottom" of the wave of the metal sheet, and not into the crest as in their asbestos-cement relatives.

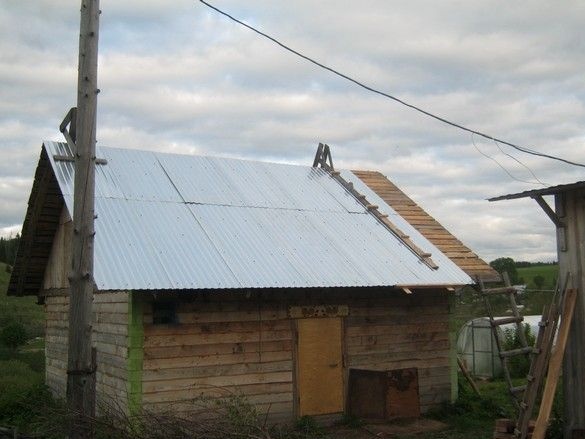

In the first picture, the principle of roofing is visible - the ability to quickly close large holes in case of sudden rain. Initially, he opened it just a little bit, on one or two sheets, then when he got used to the installation, he became bolder, and began to dismantle several bands at once. Moving around the crate is quite convenient - like stairs. The last sheets on the first side of the roof had to be fixed from the “roof” stairs, for this, it was moved to its original position in advance. At each rearrangement, the ground-to-roof staircase was “seized” by two self-tapping screws to the laths of the crate or stoppers.

It all took half a day.

Sade In

It was possible to start the installation of the roof on the second side of the roof only a few days later - it worked pretty well and had to be postponed. Well, anyway - the holes in the roof became half as much, and then the bread. Finally, the sky cleared, and it became possible to work on the roof, although the weather was windy, which was not welcomed by safety measures, but there was nowhere to go, I had to do everything, doubly carefully and carefully.

This side of the roof is somewhat more complicated - the edge is higher from the ground and there is a chimney. But there is already a recent skill, which is also a lot.

Started from the other edge of the roof, so it was more convenient to wield with your right hand. The day turned out to be, though windy, but without a threatening view of the clouds, so that it was exposed more decisively - immediately across a third of the area. The chimney, at one time, was sealed into the roof quite qualitatively, as far as this can be done without the use of special roof parts, so it was decided to leave the seal unchanged by “integrating” it into the new roof. This greatly simplified and accelerated the matter. Otherwise, everything is the same as on the previous side.

Toward evening rose, literally a barrage of wind and an extremely unsuccessful direction - straight out the window. There was not closed one strip of two sheets, on the overhang of the pediment. It was decided not to risk it again, and wait for a more favorable weather, especially since the attic space was completely closed.

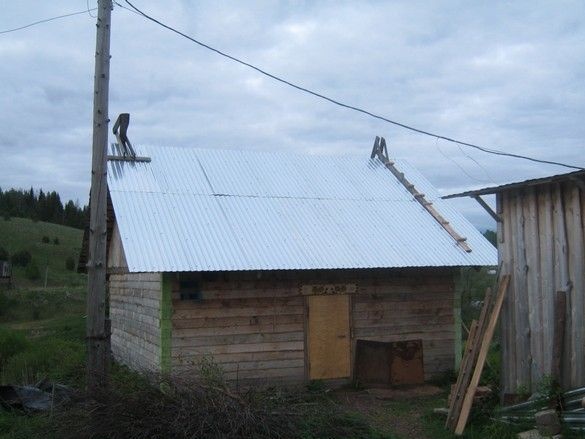

A few days later it became quieter and drier. I finished the edge and went in for a skate.

The skate bent independently from strips cut from a flat sheet of galvanized steel. The sheet fell a little thinner - 0.45 mm, it was cut very well with scissors.The whole sheet was marked and cut into three equal parts, their length was almost enough for my 7 meters with a tail, I still had to use a small piece. On both sides of the fold line of the cut billet, boards with a smooth edge were installed and fastened at the edges with clamps. For a more or less even bend, the force cannot be applied to one point - the resulting part will be wavy. It is better to bend, clicking on the part through the board, long, equal to or slightly smaller than the part.

I pulled the finished elements of the ridge onto the roof and fixed it, here it is necessary to fix it so that the roofing screws with rubber bands fall through the ridge, into the crest of the sheet wave. Voila! Down with the buckets and basins in the attic, long live the rain!

After the ritual dance of joy, it remains only to collect the slats and pull out the carnations, but to collect, twist the old ruberoid - it is planned to be used in concrete work.