Greetings the inhabitants of our site!

The fabrics from which modern things of large chain stores are sewn - alas, for the most part they cannot boast of quality. As a result, our favorite things, such as shirts, trousers, hats and sweaters, are worn out literally during the season. And surely, many people thought about how to extend life honestly to say not so old things. For these purposes, a “miracle device” is simply necessary - a machine for removing spools.

This copy was purchased by me back in the fall of last year in the entire well-known fixed price store - Fixprice. The cost of the device at the time of purchase was only 50 rubles. The machine has the following specifications:

So, I came home, “updated” the sweater with the help of a new purchase and that’s it, the batteries are dead ...

And he used good alkaline batteries for a well-known manufacturer who assures us that his products last up to ten times longer.

Next in line is a ball T-shirt. On it, the spools were not very noticeable, but still it was decided to walk on them with a new Chinese gadget. Alkaline batteries were not at hand. I found a couple of saline, which I bought some time ago in the same fixed price store.

On such a power source, the machine worked for a little more than a minute, then the engine speed began to fall, and further processing of the fabric became impossible.

So, it was decided to remake the machine to remove the spools, namely, transfer it to power from a can of a lithium-ion battery.

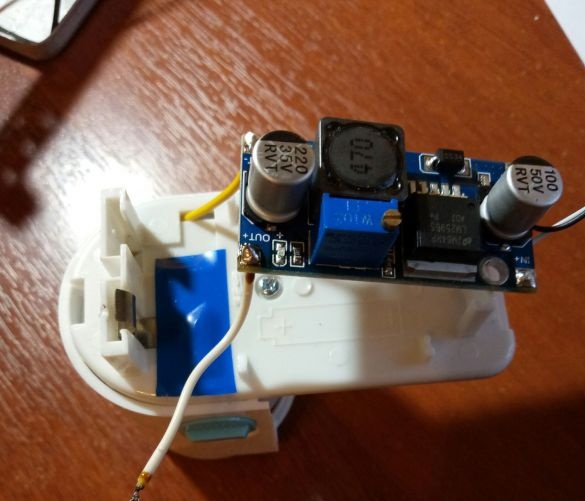

Among the available, a 14,500 AA can was selected; it fits perfectly in the battery compartment. I soldered a charge control and deep discharge protection module to the battery. All this was installed in the plastic case of the machine, while all the interfering parts of the case were removed using side cutters. Soldered the wires, closed the case and turned on the device. The machine hummed and warmed up literally in seconds. It became clear that you can’t operate it like that - the engine will burn. Since there was a circuit for the LM2596 dc-dc down converter in the presence, it was decided to include it in the circuit.

That's just to post all this electronics there’s no way inside the typewriter’s case, there’s too little space, and you can’t bring any of the parts out, since the typewriter will be uncomfortable to hold in your hand.

But in the world famous Chinese online store - aliexpress, accidentally stumbled upon such a product:

Its price is 10-odd times higher than my current copy, and the device is powered, as you can see, from a network of 220 volts.

I decided to "bind" my device to the outlet. The only difference will be that in my case the power supply will be external. I used this one:

This is an old charger from a Samsung push-button phone. Charging has good characteristics: input 100-220V, 0.15A, output - 5V, 0.7A. I think it is ideal for such a rework.

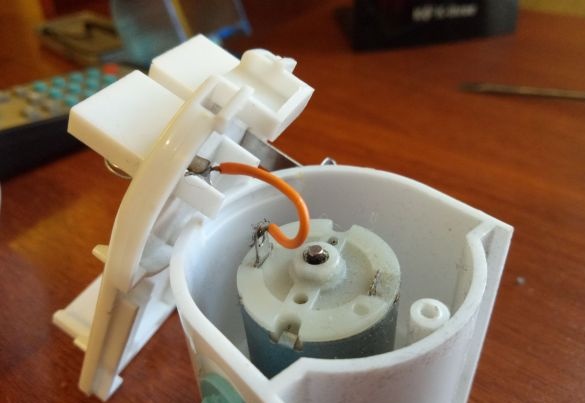

So, we disassemble the machine.

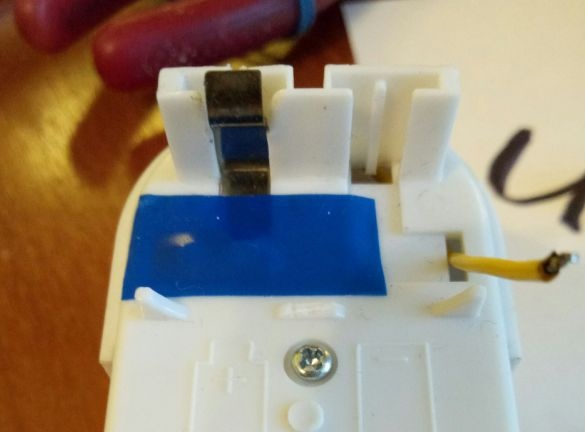

The dc-dc down converter module is located in the battery compartment of the device.

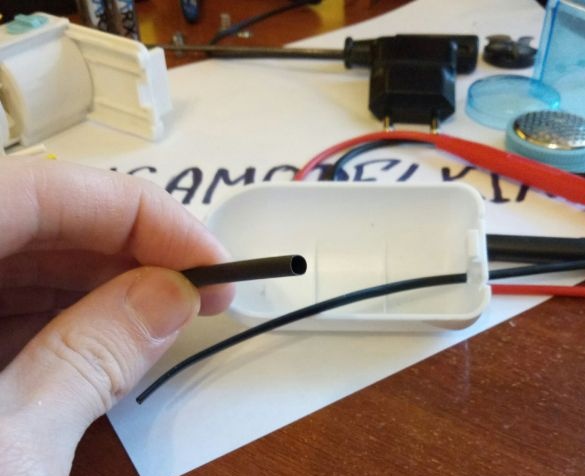

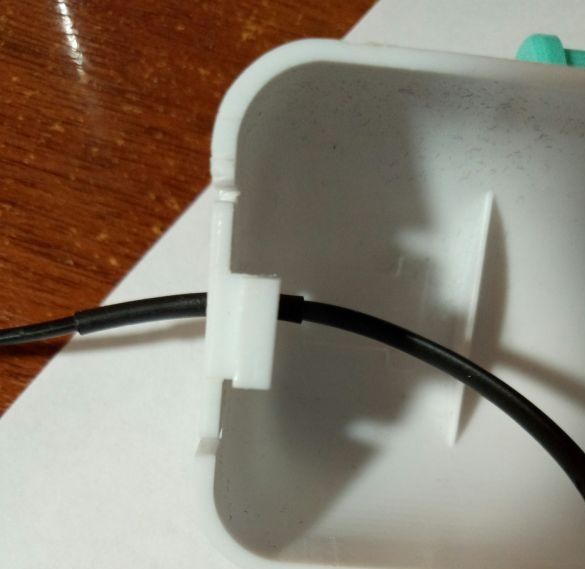

In the back of the cover of the battery compartment, you need to make a hole in which we will extend the power supply cable. The hole can be drilled with a small drill with a diameter of 2-3 mm (depending on the thickness of the wire), or you can simply cut it with a breadboard knife, since the plastic of which the gadget’s body is made does not have special strength and can be easily machined with almost any sharpened tool a tool, be it a screwdriver, knife or even scissors.

When you have dealt with the top cover of the case, we pass the wire through the hole made for it and put on it a small piece of heat-shrink tube in order to increase the strength at the bend point (the contact of the wire from the power supply with the case).

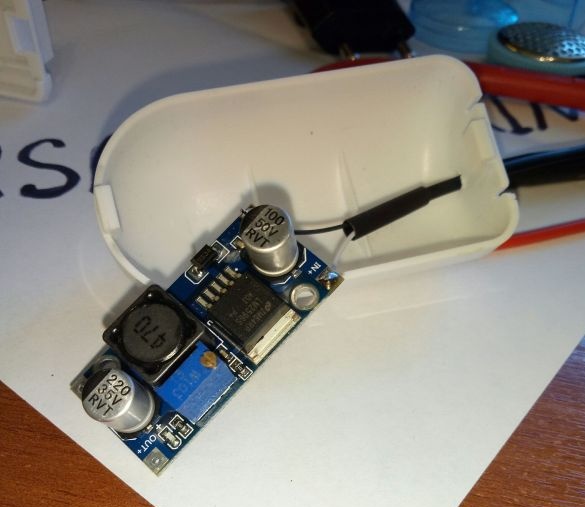

Then we solder the incoming wires to the corresponding contacts of the board of the dc-dc step-down voltage converter. There is nothing complicated here, all contacts are marked, it is difficult to make a mistake. We fix a thermoshrinkable tube by means of a lighter or the hair dryer.

Next, you need to configure the board of the step-down voltage converter. To do this, turn on the charger (power supply) and, using a multimeter and a tuning resistor on the board, set the voltage corresponding to two AA batteries connected in series - about 3V (a little more, about 3.1-3.3V).

When I connected the voltage-reducing module, a surprise was waiting for me. The fact is that of all the LM2596 DC-DC boards I ordered, only on this instance the LED indicator turned out to be blue. On all other boards from the same kit, the LED emits red. And by the way, the boards turned out to be different. If you take the step-down module with a red LED, then when you turn on the machine, the LED for a while completely turns off. Then it gradually restores the power of the glow, but at the same time it does not affect the operation of the machine for removing the spools (well, at least I did not notice anything unusual). I decided to leave this scarf with a blue LED, since the machine’s body is blue and white, and when the power supply is turned on, the LED turns on, the light of which shines through the white cover of the battery compartment, and the case turns almost all blue. It looks pretty interesting.

Then, the lower part of the positive contact of the machine must be insulated with electrical tape in order to avoid contact with the converter board.

Next, solder the wires coming from the motor of the machine to the outputs of the buck converter. It is important to observe the polarity, since if you mix up "+" and "-", the motor will rotate in the wrong direction, so the blades will not be able to remove the spools.

The step-down voltage converter module must be placed inside the battery compartment.

After making sure that the battery cover is closed and the voltage converter board does not interfere, we fix the board with hot glue.We check whether everything is done correctly and close the lid.

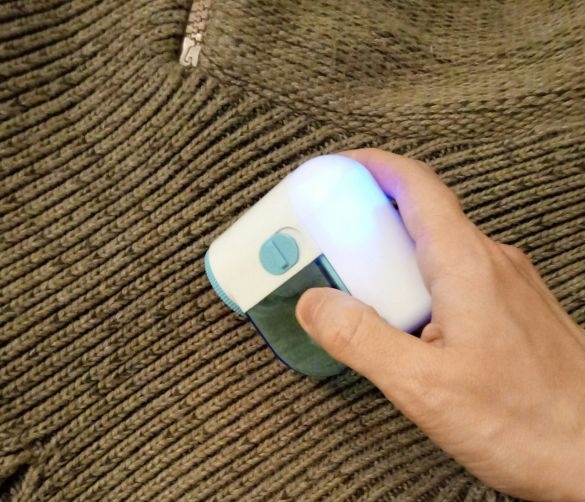

You can start the tests. The subject will be a woolen sweater.

The machine did an excellent job. It took about 10 minutes to clean the product. During this time, the body of the machine warmed up a bit and became warm, but I think this is normal. It seems that when running on batteries, the motor heats up even more. Perhaps this is due to the fact that it took more time to process the fabric.

Summarize. Now the machine can be used without worrying about the presence of spare batteries in the house. Prior to remaking, this gadget honestly did a poor job of handling woolen things, such as sweaters and winter hats made of thick wool. The surface of such things rolls pretty quickly, while forming quite dense spools. When working from 2 AA batteries, the machine periodically seemed to bind and stop. When working from the power supply unit, such problems do not arise. The machine’s motor runs smoothly without interruption. During the test, it seemed to me that the power can be slightly increased, which was actually done by increasing the voltage with the help of a tuning resistor on the board of a dc-dc step-down voltage converter. Voltage increased quite a bit by 0.2V. It is impossible to connect the machine directly to a 5-volt power supply (without a step down dc-dc converter), as the motor simply burns out. The only thing that someone might not like is that things will have to be processed right next to the outlet. But for me this is not a problem.

Thank you for attention. See you soon!