The stained-glass window in the Tiffany technique is a rather ingenious way of connecting curly glasses. Not without some drawbacks - special materials and equipment are required, however, we must pay tribute to the American comrade. To get a picture, its glass elements are cut out and adjusted, their edges are edged with copper foil with a sticky layer - voila! Using a conventional soldering iron, connect the parts to the whole. As a result, it is permissible to make stained glass elements much more bizarre, small, which allows the drawing to be very detailed.

I must say that the stained glass window is in itself, such a thing, with fingers moving in the air, involuntarily associated with antiquity. Images of lancet windows of an ancient castle, tapestries, shields and weapons on the walls. Gothic of various kinds, the church at last. In a word, such a collective image of rarity. It is clear that all kinds of metal gizmos of this kind cannot sparkle like a freshly minted coin, from a long circulation an oxide film forms on them, which remains in hard-to-reach places of the product, as long as it is not polished. This film is called patina, its color depends on the metal. Her appearance - smoothly transitioning from very light, in open, shabby places, to dark in hard-to-reach places, causes a rapid heartbeat among antique dealers and lovers of antiquity. Patina, in addition to a sort of “imprint of time”, just looks beautiful - a kind of mature, wise beauty against youth and frivolity.

The natural patina is formed very slowly, this is really the “life experience” of the piece of iron, however, with the help of simple reagents, it is quite possible to make this kind of film in an artificial way, which often very decorates the product. Very often, patination is used in jewelry. The processes in jewelers are more complex, probably due to the use of precious metals that are more resistant to oxidation. Patina for products from copper alloys, applied very simply, there are simple recipes for different colors. In our case, we are talking about applying patina to the surface of a tin-lead alloy (solder seam) and there are some complications. Firstly, the specific place of application is surrounded by glasses, which we do not have the moral right to distort in the preparation of metal (stripping).Secondly, the soldering is carried out without cleaning the surface (foil on the glass) and therefore acid fluxes are used, including a special “solder fat”, the remains of which are even more difficult to wash off. Residues of not washed flux, as a rule, are the most common cause of failures when applying patina in stained glass.

Collecting your first stained-glass window - lamp shade for a picture lamp, I encountered a problem when patinating stitches. Beginning to study the process, I discovered that the problem of high-quality patination is quite common in stained-glass window business and arises not only among beginners. As a result of the work, material was collected and summarized, a number of experiments were conducted. As a result, it turned out in simple ways to achieve an acceptable color of the seams.

Generally speaking, two colors are most often used for chemical staining (patination) of stitches in the Tiffany stained glass technique - black and bronze. The composition for giving a bronze color is not recommended for beginners - it is more moody, more conditions when applied, to obtain a smooth beautiful film. Moreover, it is not particularly like a real patina. Black color to the seams, give chemicals based on copper sulfate. These compounds are much more flexible, after appropriate treatment they are very similar to the real “historical” patina and they are preferred much more often. Your humble servant decided to start with it.

What was used in the work.

Tools, materials.

Brush with hard (cut) bristles, dishes, cotton rags. Means for applying black patina or copper sulfate, dishwashing detergent, hair dryer, rubber gloves, thin brush. Protective varnish for the seams of the stained glass window "Antioxidant".

For experiments, I made a small sample - I cut a piece of 4mm glass into squares, wrapped 6 pieces of the very inferior Chinese foil and soldered it. The edges of the glasses on the grinder did not grind. Chinese foil, by the way, is not so bad - the adhesion of the glue is a bit smaller and the size range is limited to integers. Given that the founding father, Comrade Tiffany, glued strips of foil with beeswax, we conclude that the people today are simply spoiled. Sample immediately after soldering.

Yes, I want to say that the key elements to the success of the procedure are time and thorough removal of flux (acid) residues. Everything is clear with the residuals - not thoroughly removing them leads to ugly spots instead of smooth color transitions, but time is not only necessary to move around, but it is important to solder the stained-glass window at a time and so that there is little time for patination. You cannot postpone. We solder, immediately wash and wipe. We take out in the sun and a draft, as soon as it is completely dry, apply a patina, wash off the residues, wipe, dry, apply a protective varnish. Not distracted.

To wash the flux, you need to choose a dishwashing detergent more generously - whatever Fairy is. We immediately bred it in a plastic soft bottle pierced with an awl stopper. So it turns out much more convenient than if pouring on a stained glass window is not diluted. We arm ourselves with a brush with hard plastic bristles - if this is a larger stained glass window than mine, you can try to pick up a shoe brush or whatever. In his case, he managed with an old toothbrush. To make it more convenient for her to wield, he molded her handle slightly at an angle, softening the base, with hot air from a hair dryer. Do not forget about rubber gloves. Water must be hot. Especially when using solder grease.

Well, nothing out of the ordinary — pour hot water and a diluted detergent on our sample, carefully wipe it with a brush. Rinse thoroughly and wipe dry with a clean cotton rag. In the summer, in the sun and the breeze, our glass dries quickly. In winter, you should probably put it on a warm stove or use a hair dryer.

Patina. Home-made patina is made from copper sulfate. Aqueous solution 3: 1. It dissolves without much desire, so you have to warm up. It is recommended to add soda ~ 1 teaspoon per 5 l of solution. A small portion of the finished solution is applied to the area of the treated seam and rubbed well with the same toothbrush.Yes, there is a moment - after washing off the solder fat, there is a good chance that its remnants stick on the brush - you should not use it further, for patination.

After complete processing of the stained-glass window, it is washed off from the chemical residues, slightly wiped with a cloth and dried. Above is a coating with a factory chemical, purchased in the same place as the other materials for the manufacture of stained glass. Such a coating, initially somewhat darker, but after light grinding, there is almost no difference.

Perhaps you can leave it like that, but much more elegantly, it turns out if the seams are sanded a little. However, it is strongly said - it is quite enough to rub it with a rough rag. Of course, all the irregularities of the soldering immediately become visible, but the general appearance and impression, which are much more, hmm, authentic. Yes, about the clumsiness of rations - an unsuccessful patina can be stained either mechanically (with steel wool or wool) or by re-soldering the stained-glass window anew. When soldering, the oxides of the old patina form some kind of difficult-to-remove islands, they are very in the way and the soldering turns out to be much more clumsy than if done right away. I had to taste these charms to the fullest - the sample had to be re-soldered several times to prepare it for the next experiment, the stained glass window also had to be redone due to an unsuccessful attempt.

After giving the patina authenticity, we protect the seams with a special varnish. Stained glass artists call it "antioxidant" - apparently a literal "machine" translation of the great and mighty English. Sold in the same place as colored glass. In principle, this is the only useful special - stained glass chemical. It gives color saturation, protects against further oxidation, repels dust somewhat. It is applied with a thin brush along the treated seams, then rubbed thoroughly with a clean cloth. I saw tips for using car wax polishes instead of such varnish, and even WD-40.

Below, finished seams on the pattern. The foil at the edges of the glass is not tinned; look only in the middle.

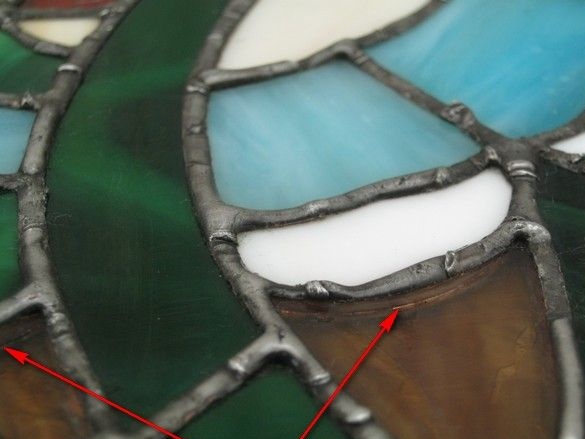

Well, the lampshade itself is a stained glass window, for which everything was started. Untreated seams and finished patina. The arrows indicate a mistake - for the version with a black patina and transparent glasses, you should pre-select the black foil from the inside, it looks more beautiful.