Good day to all fishing and homemade.

Today I will show and talk about the process of manufacturing a mold for casting silicone baits. I think everyone understands that the manufacture of bait itself significantly reduces the cost of the bait itself and this form is the most important in this process.

Materials and tools:

1. alabaster

2. water

3. vibrotail which we will copy

4. laundry soap

5. stir stick

6. kneading capacity

7. tassel

8. knife

9. thin drill

10. foam

11. plasticine

Step 1

Determine the size of the form. The shape should be such that our bait fits comfortably and the walls have a thickness of at least 5 mm.

Step 2

According to these sizes, we make foam formwork and glue it with glue and tape. Then we stick it on the base and coat everything with plasticine.

Step 3

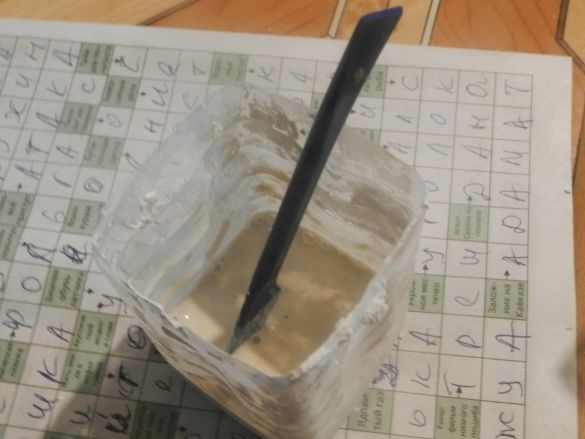

Knead the solution. To do this, mix the alabaster with water until the consistency of thick sour cream.

Step 4

We pour the solution into the formwork exactly to half and lay the bait to half as well and wait until the solution hardens.

Step 5

After the solution has hardened, we make indentations along the edges of the mold with a knife so that the mold remains even during casting, grease everything with a solution of laundry soap in water and fill the second layer to the top. We are waiting for the solution to solidify.

Step 6

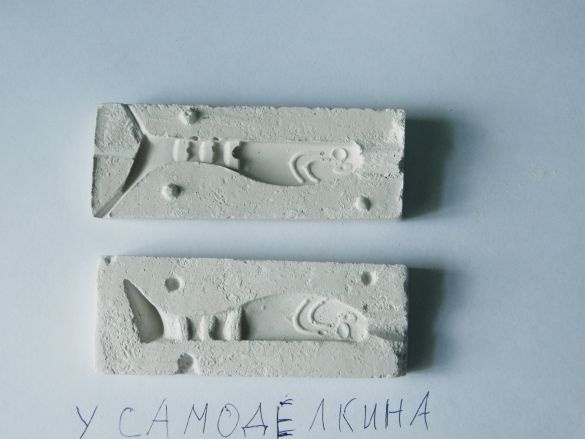

Final processing. Separate the form, get the bait. We make passages for air exit, drill a hole for pouring silicone with a drill and the whole form is ready.